$20.00

Language

EnglishModel of Truck

SA6D114E-2, SAA6D114E-2Region

JapanType of Document

Workshop ManualType of Truck

Diesel EngineIllustrated factory Workshop Manual for Komatsu Diesel Engines Models SA6D114E-2 and SAA6D114E-2.

This manual will assist you in diagnosing, repairing, and adjusting for your diesel engine.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

SA6D114E-2

SAA6D114E-2

Format: PDF, 442 pages

Language: English

Table of Contents:

GENERAL

APPLICABLE MACHINE

SPECIFICATION

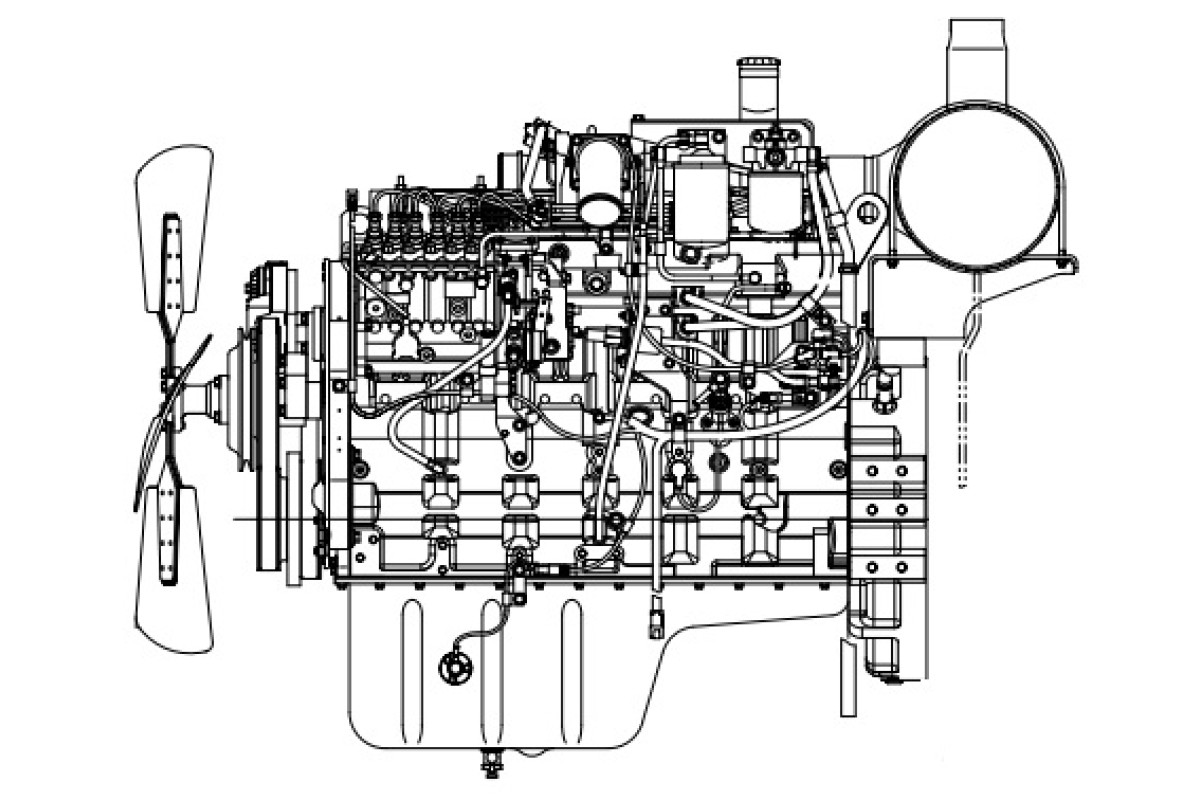

OVERALL DRAWING

WEIGHT TABLE

ENGINE PERFORMANCE CURVE

STRACTURE AND FUNCTION

AIR INTAKE DEVICE

EXHAUST MANIFOLD

AIR CLEANER

TURBOCHARGER

AFTERCOOLER

CYLINDER HEAD

CYLINDER BLOCK

CYLINDER LINER

MAIN CIRCULATION PART

CRANK SHAFT

PISTON・PISTON RING・PISTON PIN

CONNECTING ROD

VIBRATION DAMPER

TIMING GEAR PORTION

FRONT GEAR COVER

CAMSHAFT TIMING PIN

TIMING GEAR

CAM SHAFT

VALVE MECHANISM

VALVE, VALVE GUIDE

ROCKER-ARM SHAFT・PUSH ROD・TAPPET

OIL PAN

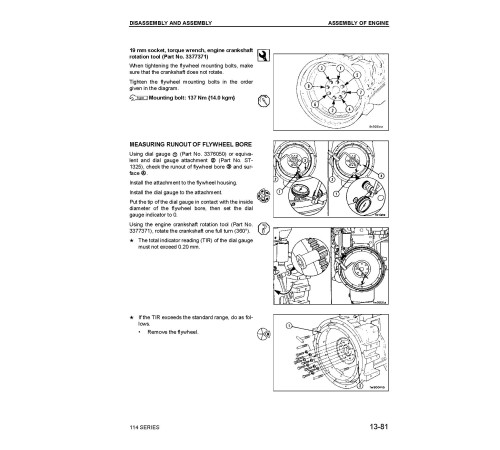

FLYWHEEL, FLYWHEEL HOUSING

LUBRICATION SYSTEM DIAGRAM

OIL PUMP

OIL FILTER, OIL COOLER

REGULATOR VALVE, SAFETY VALVE

FUEL SYSTEM DIAGRAM

FUEL INJECTION PUMP

TIMING LOCK PIN OF FUEL INJECTION PUMP

FUEL FILTER

FUEL INJECTION NOZZLE

FUEL CUT SOLENOID

COOLING SYSTEM DIAGRAM

WATER PUMP DRIVE

WATER PUMP (WITH ONE-PIECE BEARING, SHAFT, ONE-PIECE WATER SEAL)

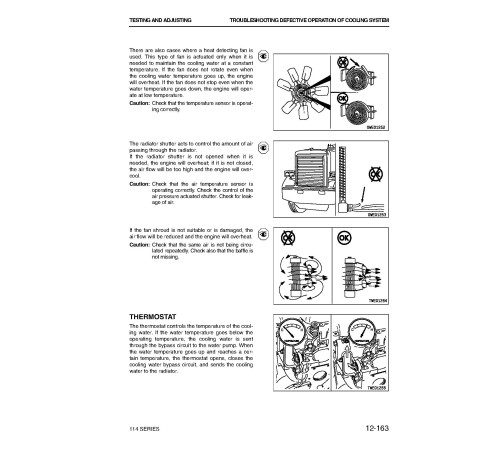

THERMOSTAT

FAN DRIVE

ALTERNATOR

STARTING MOTOR

STARTING AID

TESTING AND ADJUSTING

SPECIAL TOOL LIST

TROUBLESHOOTING DEFECTIVE ACTUATION OF INTAKE AND EXHAUST SYSTEM

MEASURING PLAY OF TURBOCHARGER ROTOR IN AXIAL AND RADIAL DIRECTION

TESTING TURBOCHARGER WESTGATE VALVE

TESTING TURBOCHARGER WESTGATE CAPSULE

TESTING ACTUATION OF TURBOCHARGER WESTGATE

REPLACING TURBOCHARGER WESTGATE ACTUATOR BOOST CAPSULE

ADJUSTING TURBOCHARGER WESTGATE ACTUATOR

MEASURING EXHAUST RESISTANCE

REPLACING TURBOCHARGER

TROUBLESHOOTING DEFECTIVE ACTUATION OF ENGINE

ADJUSTING VALVE CLEARANCE

TROUBLESHOOTING DEFECTIVE ACTUATION OF LUBRICATING SYSTEM

FUEL INJECTION PUMP CALIBRATION DATA

RUNNING IN STANDARD

PERFORMANCE TEST CRITERIA

TESTING FUEL FEED PUMP

ADJUSTING FUEL CUT-OFF SOLENOID

TESTING FOR AIR INSIDE THE FUEL SYSTEM

TESTING WATER SEPARATOR, FUEL FILTER

TESTING HIGH-PRESSURE FUEL PIPING

TESTING FUEL INJECTION NOZZLE

TESTING FUEL DRAIN PIPING

BLEEDING AIR FROM FUEL SYSTEM

ADJUSTING TIMING OF FUEL INJECTION PUMP

TROUBLESHOOTING DEFECTIVE OPERATION OF COOLING SYSTEM

STANDARD VALUE TABLE FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

TROUBLESHOOTING OF ENGINE (S MODE)

DISASSEMBLY AND ASSEMBLY

SPECIAL TOOL LIST

OUTLINE OF DISASSEMBLY AND ASSEMBLY OF ENGINE

OVERALL DISASSEMBLY OF ENGINE

ASSEMBLY OF ENGINE

REPAIR AND REPLACEMENT OF PARTS

OUTLINE

REPAIR METHODS FOR SCREWS USING COIL THREAD INSERT

METHOD FOR USING TAPER THREAD PLUGS TO SEAL POCKETS AND SMALL HOLES IN CASTINGS

METHOD FOR REPAIRING TAPER THREAD PLUG HOLES WORN BY LARGE SIZE COPPER PLATED PLUGS

METHOD OF USING FILLER METAL IN EMERGENCY REPAIRS

INSPECTION FOR REUSE OF CYLINDER BLOCK

INSTALLATION OF EXPANSION PLUGS

INSTALLATION OF EXPANSION PLUG TO CAMSHAFT HOLE

REMOVAL OF CAMSHAFT BUSHING

INSTALLATION OF CAMSHAFT BUSHING

CLEANING AND INSPECTION OF CYLINDER LINERS BEFORE REUSING THEM

CLEANING AND INSPECTION OF PISTON BEFORE REUSING IT

CLEANING AND INSPECTION OF CRANKSHAFT BEFORE REUSING IT

REPLACEMENT OF CRANKSHAFT GEAR

CLEANING AND INSPECTION OF MAIN BEARINGS BEFORE REUSING THEM

CLEANING AND INSPECTION OF MAIN BEARING CAPS AND MOUNTING BOLTS BEFORE REUSING THEM

CLEANING AND INSPECTION OF CONNECTING ROD BEARINGS BEFORE REUSING THEM

CLEANING AND INSPECTION OF CONNECTING RODS BEFORE REUSING THEM

INSPECTION OF CONNECTING RODS FOR BEND AND TORSION

REPLACEMENT OF CONNECTING ROD BUSHINGS

REPLACEMENT OF VALVE INSERTS OF CYLINDER HEAD

REPLACEMENT OF VALVE GUIDES OF CYLINDER HEAD

CYLINDER HEAD-PRESSURE TEST

VACUUM TEST ON VALVE SEATS OF CYLINDER HEAD

CLEANING AND INSPECTION OF CYLINDER HEAD BOLTS

This manual will assist you in diagnosing, repairing, and adjusting for your diesel engine.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

SA6D114E-2

SAA6D114E-2

Format: PDF, 442 pages

Language: English

Table of Contents:

GENERAL

APPLICABLE MACHINE

SPECIFICATION

OVERALL DRAWING

WEIGHT TABLE

ENGINE PERFORMANCE CURVE

STRACTURE AND FUNCTION

AIR INTAKE DEVICE

EXHAUST MANIFOLD

AIR CLEANER

TURBOCHARGER

AFTERCOOLER

CYLINDER HEAD

CYLINDER BLOCK

CYLINDER LINER

MAIN CIRCULATION PART

CRANK SHAFT

PISTON・PISTON RING・PISTON PIN

CONNECTING ROD

VIBRATION DAMPER

TIMING GEAR PORTION

FRONT GEAR COVER

CAMSHAFT TIMING PIN

TIMING GEAR

CAM SHAFT

VALVE MECHANISM

VALVE, VALVE GUIDE

ROCKER-ARM SHAFT・PUSH ROD・TAPPET

OIL PAN

FLYWHEEL, FLYWHEEL HOUSING

LUBRICATION SYSTEM DIAGRAM

OIL PUMP

OIL FILTER, OIL COOLER

REGULATOR VALVE, SAFETY VALVE

FUEL SYSTEM DIAGRAM

FUEL INJECTION PUMP

TIMING LOCK PIN OF FUEL INJECTION PUMP

FUEL FILTER

FUEL INJECTION NOZZLE

FUEL CUT SOLENOID

COOLING SYSTEM DIAGRAM

WATER PUMP DRIVE

WATER PUMP (WITH ONE-PIECE BEARING, SHAFT, ONE-PIECE WATER SEAL)

THERMOSTAT

FAN DRIVE

ALTERNATOR

STARTING MOTOR

STARTING AID

TESTING AND ADJUSTING

SPECIAL TOOL LIST

TROUBLESHOOTING DEFECTIVE ACTUATION OF INTAKE AND EXHAUST SYSTEM

MEASURING PLAY OF TURBOCHARGER ROTOR IN AXIAL AND RADIAL DIRECTION

TESTING TURBOCHARGER WESTGATE VALVE

TESTING TURBOCHARGER WESTGATE CAPSULE

TESTING ACTUATION OF TURBOCHARGER WESTGATE

REPLACING TURBOCHARGER WESTGATE ACTUATOR BOOST CAPSULE

ADJUSTING TURBOCHARGER WESTGATE ACTUATOR

MEASURING EXHAUST RESISTANCE

REPLACING TURBOCHARGER

TROUBLESHOOTING DEFECTIVE ACTUATION OF ENGINE

ADJUSTING VALVE CLEARANCE

TROUBLESHOOTING DEFECTIVE ACTUATION OF LUBRICATING SYSTEM

FUEL INJECTION PUMP CALIBRATION DATA

RUNNING IN STANDARD

PERFORMANCE TEST CRITERIA

TESTING FUEL FEED PUMP

ADJUSTING FUEL CUT-OFF SOLENOID

TESTING FOR AIR INSIDE THE FUEL SYSTEM

TESTING WATER SEPARATOR, FUEL FILTER

TESTING HIGH-PRESSURE FUEL PIPING

TESTING FUEL INJECTION NOZZLE

TESTING FUEL DRAIN PIPING

BLEEDING AIR FROM FUEL SYSTEM

ADJUSTING TIMING OF FUEL INJECTION PUMP

TROUBLESHOOTING DEFECTIVE OPERATION OF COOLING SYSTEM

STANDARD VALUE TABLE FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

TROUBLESHOOTING OF ENGINE (S MODE)

DISASSEMBLY AND ASSEMBLY

SPECIAL TOOL LIST

OUTLINE OF DISASSEMBLY AND ASSEMBLY OF ENGINE

OVERALL DISASSEMBLY OF ENGINE

ASSEMBLY OF ENGINE

REPAIR AND REPLACEMENT OF PARTS

OUTLINE

REPAIR METHODS FOR SCREWS USING COIL THREAD INSERT

METHOD FOR USING TAPER THREAD PLUGS TO SEAL POCKETS AND SMALL HOLES IN CASTINGS

METHOD FOR REPAIRING TAPER THREAD PLUG HOLES WORN BY LARGE SIZE COPPER PLATED PLUGS

METHOD OF USING FILLER METAL IN EMERGENCY REPAIRS

INSPECTION FOR REUSE OF CYLINDER BLOCK

INSTALLATION OF EXPANSION PLUGS

INSTALLATION OF EXPANSION PLUG TO CAMSHAFT HOLE

REMOVAL OF CAMSHAFT BUSHING

INSTALLATION OF CAMSHAFT BUSHING

CLEANING AND INSPECTION OF CYLINDER LINERS BEFORE REUSING THEM

CLEANING AND INSPECTION OF PISTON BEFORE REUSING IT

CLEANING AND INSPECTION OF CRANKSHAFT BEFORE REUSING IT

REPLACEMENT OF CRANKSHAFT GEAR

CLEANING AND INSPECTION OF MAIN BEARINGS BEFORE REUSING THEM

CLEANING AND INSPECTION OF MAIN BEARING CAPS AND MOUNTING BOLTS BEFORE REUSING THEM

CLEANING AND INSPECTION OF CONNECTING ROD BEARINGS BEFORE REUSING THEM

CLEANING AND INSPECTION OF CONNECTING RODS BEFORE REUSING THEM

INSPECTION OF CONNECTING RODS FOR BEND AND TORSION

REPLACEMENT OF CONNECTING ROD BUSHINGS

REPLACEMENT OF VALVE INSERTS OF CYLINDER HEAD

REPLACEMENT OF VALVE GUIDES OF CYLINDER HEAD

CYLINDER HEAD-PRESSURE TEST

VACUUM TEST ON VALVE SEATS OF CYLINDER HEAD

CLEANING AND INSPECTION OF CYLINDER HEAD BOLTS

General

Language

EnglishModel of Truck

SA6D114E-2, SAA6D114E-2Region

JapanType of Document

Workshop ManualType of Truck

Diesel EngineReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.