$20.00

Language

EnglishModel of Truck

4D95LWE-5, S4D95LWE-5Region

GermanyType of Document

Workshop ManualType of Truck

Diesel EngineIllustrated factory Workshop Manual for Komatsu Diesel Engines Models 4D95LWE-5 and S4D95LWE-5.

This manual will assist you in diagnosing, repairing, and adjusting for your diesel engine.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

4D95LWE-5

S4D95LWE-5

Format: PDF, 198 pages

Language: English

Table of Contents:

SEN04408-00 WA65-6, WA70-6, WA80-6

SAFETY

FOREWORD

GENERAL

General

General view

4D95LWE-5

S4D95LWE-5

Specifications

General assembly drawing

4D95LWE-5 LEFT SIDE VIEW (WA65HH-6)

4D95LWE-5 RIGHT SIDE VIEW (WA65HH-6)

4D95LWE-5 FRONT VIEW (WA65HH-6)

4D95LWE-5 REAR VIEW (WA65HH-6)

S4D95LWE-5 LEFT SIDE VIEW (WA80HH-6)

S4D95LWE-5 RIGHT SIDE VIEW (WA80HH-6)

S4D95LWE-5 FRONT VIEW (WA80HH-6)

S4D95LWE-5 REAR VIEW (WA80HH-6)

DIMENSION TABLE

Engine performance curve

4D95LWE-5 [Applicable machine: WA65-HH-6]

4D95LWE-5 [Applicable machine: WA70-HH-6]

4D95LWE-5 [Applicable machine: WA80-HH-6]

Weight table

STRUCTURE AND FUNCTION

General structure

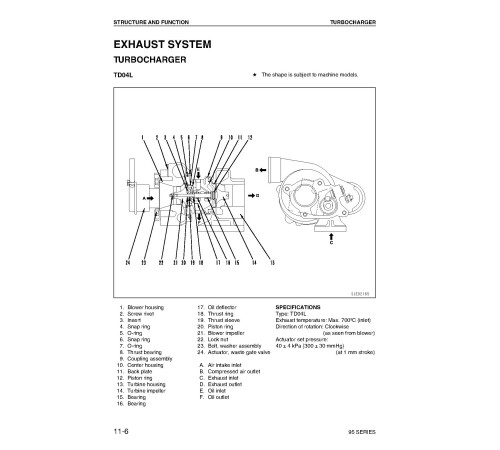

EXHAUST SYSTEM

ENGINE BODY

LUBRICATION SYSTEM

FUEL SYSTEM

COOLING STSTEM

ELECTRICAL SYSTEM

TESTING AND ADJUSTING

Performance test

Run-in standard

Performance test criteria

Testing and adjusting data

Testing and adjusting tools list

Intake and exhaust system

Adjusting valve clearance

Engine body

Measuring compression pressure

Fuel system

Adjusting fuel injection pressure (Cracking pressure)

Shim data for adjusting injection pressure

Testing and adjusting fuel injection timing

Table of injection pumps using plunger with stepped lead

Adjusting fuel injection rate

Governor adjustment standard

Troubleshooting

Method of using troubleshooting charts

Points on troubleshooting

S-1 Starting performance is poor (Starting always takes time)

S-2 Engine does not start

S-3 Engine does not pick up smoothly (Follow-up is poor)

S-4 Engine stops during operations

S-5 Engine does not rotate smoothly

S-6 Engine lacks output (no power)

S-7 Exhaust gas is black (incomplete combustion)

S-8 Oil consumption is excessive (or exhaust gas is blue)

S-9 Oil becomes contaminated quickly

S-10 Fuel consumption is excessive

S-11 Oil is in coolant, or coolant spurts back, or coolant level goes down

S-12 Oil pressure lamp lights up (drop in oil pressure)

S-13 Oil level rises

S-14 Coolant temperature becomes too high (overheating)

S-15 Abnormal noise is made

S-16 Vibration is excessive

DISASSEMLY AND ASSEMBLY

General disassembly

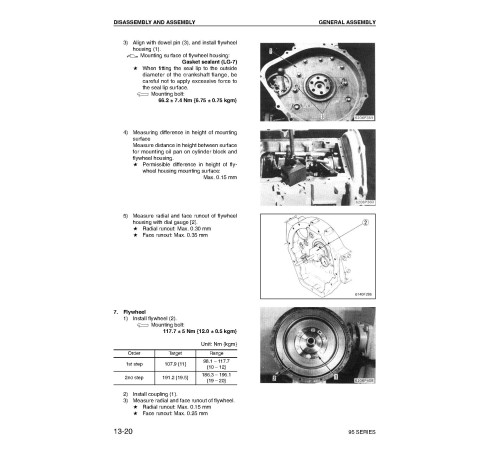

General assembly

MAINTENANCE STANDARD

Turbocharger

Cylinder head

Valve, valve guide

Rocker arm shaft, push rod and tappet

Cylinder block

Cylinder

Crankshaft

Camshaft

Timing gear (Helical gear)

Flywheel and flywheel housing

Piston, piston ring and piston pin

Connecting rod

Regulator valve

Water pump and thermostat

REPAIR AND REPLACEMENT OF PARTS

Grinding cylinder head mounting surface

Replacing valve guide

Grinding valve

Replacing camshaft bushing

Replacing crankshaft gear

Testing and adjusting fuel injection timing

Replacing flywheel ring gear

Procedure for pressure test

Cylinder liner

(special restoration part)

Machining drawing for cylinder block bore

Additional machining of cam journal

Grinding crankshaft

Replacing connecting rod small end bushing

This manual will assist you in diagnosing, repairing, and adjusting for your diesel engine.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

4D95LWE-5

S4D95LWE-5

Format: PDF, 198 pages

Language: English

Table of Contents:

SEN04408-00 WA65-6, WA70-6, WA80-6

SAFETY

FOREWORD

GENERAL

General

General view

4D95LWE-5

S4D95LWE-5

Specifications

General assembly drawing

4D95LWE-5 LEFT SIDE VIEW (WA65HH-6)

4D95LWE-5 RIGHT SIDE VIEW (WA65HH-6)

4D95LWE-5 FRONT VIEW (WA65HH-6)

4D95LWE-5 REAR VIEW (WA65HH-6)

S4D95LWE-5 LEFT SIDE VIEW (WA80HH-6)

S4D95LWE-5 RIGHT SIDE VIEW (WA80HH-6)

S4D95LWE-5 FRONT VIEW (WA80HH-6)

S4D95LWE-5 REAR VIEW (WA80HH-6)

DIMENSION TABLE

Engine performance curve

4D95LWE-5 [Applicable machine: WA65-HH-6]

4D95LWE-5 [Applicable machine: WA70-HH-6]

4D95LWE-5 [Applicable machine: WA80-HH-6]

Weight table

STRUCTURE AND FUNCTION

General structure

EXHAUST SYSTEM

ENGINE BODY

LUBRICATION SYSTEM

FUEL SYSTEM

COOLING STSTEM

ELECTRICAL SYSTEM

TESTING AND ADJUSTING

Performance test

Run-in standard

Performance test criteria

Testing and adjusting data

Testing and adjusting tools list

Intake and exhaust system

Adjusting valve clearance

Engine body

Measuring compression pressure

Fuel system

Adjusting fuel injection pressure (Cracking pressure)

Shim data for adjusting injection pressure

Testing and adjusting fuel injection timing

Table of injection pumps using plunger with stepped lead

Adjusting fuel injection rate

Governor adjustment standard

Troubleshooting

Method of using troubleshooting charts

Points on troubleshooting

S-1 Starting performance is poor (Starting always takes time)

S-2 Engine does not start

S-3 Engine does not pick up smoothly (Follow-up is poor)

S-4 Engine stops during operations

S-5 Engine does not rotate smoothly

S-6 Engine lacks output (no power)

S-7 Exhaust gas is black (incomplete combustion)

S-8 Oil consumption is excessive (or exhaust gas is blue)

S-9 Oil becomes contaminated quickly

S-10 Fuel consumption is excessive

S-11 Oil is in coolant, or coolant spurts back, or coolant level goes down

S-12 Oil pressure lamp lights up (drop in oil pressure)

S-13 Oil level rises

S-14 Coolant temperature becomes too high (overheating)

S-15 Abnormal noise is made

S-16 Vibration is excessive

DISASSEMLY AND ASSEMBLY

General disassembly

General assembly

MAINTENANCE STANDARD

Turbocharger

Cylinder head

Valve, valve guide

Rocker arm shaft, push rod and tappet

Cylinder block

Cylinder

Crankshaft

Camshaft

Timing gear (Helical gear)

Flywheel and flywheel housing

Piston, piston ring and piston pin

Connecting rod

Regulator valve

Water pump and thermostat

REPAIR AND REPLACEMENT OF PARTS

Grinding cylinder head mounting surface

Replacing valve guide

Grinding valve

Replacing camshaft bushing

Replacing crankshaft gear

Testing and adjusting fuel injection timing

Replacing flywheel ring gear

Procedure for pressure test

Cylinder liner

(special restoration part)

Machining drawing for cylinder block bore

Additional machining of cam journal

Grinding crankshaft

Replacing connecting rod small end bushing

General

Language

EnglishModel of Truck

4D95LWE-5, S4D95LWE-5Region

GermanyType of Document

Workshop ManualType of Truck

Diesel EngineReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.