$10.00

Language

EnglishModel of Truck

BR580JG-1Region

JapanType of Document

Field Assembly ManualType of Truck

Mobile CrusherIllustrated factory Field Assembly Manual for Komatsu Mobile Crushers Models BR580JG-1.

This manual will assist you in for your mobile crusher.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

BR580JG-1 (SN: 01001-)

Format: PDF, 155 pages

Language: English

Table of Contents:

PREFACE

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

OUTLINE OF WORK PROCESS

FLOW OF ASSEMBLY PROCEDURE

KIT LAYOUT DRAWING

PACKING POSTURE FOR TRANSPORTATION

LIST OF TOOLS FOR FIELD ASSEMBLING

TIGHTENING TORQUE

COATING MATERIALS LIST

LIST OF SEPARATELY SHIPPED PARTS

A. ASSEMBLY PROCEDURE

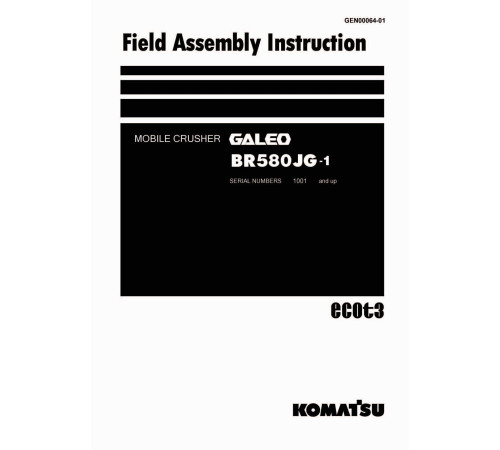

A- 1. PREPARATION FOR INSTALLATION OF CRUSHER ASSEMBLY

A- 2. INSTALLATION OF CRUSHER ASSEMBLY

A- 3. INSTALLATION OF STEPS

A- 4. INSTALLATION OF HANDRAILS

A- 5. INSTALLATION OF FLOOR

A- 6. INSTALLATION OF CRUSHER MOTOR HOSES

A- 7. INSTALLATION OF LOCK CYLINDER HOSES

A- 8. INSTALLATION OF CRUSHER WIRING

A- 9. INSTALLATION OF CRUSHER COVERS

A-10. INSTALLATION OF GUARD ASSEMBLY

A-11. INSTALLATION OF DUST PLATE ASSEMBLY

A-12. INSTALLATION OF SECOND CHUTES

A-13. INSTALLATION OF FEEDER MOTOR

A-14. POSTURE OF OPEN/CLOSE HOPPER

A-15. INSTALLATION OF HOPPER (R.H.)

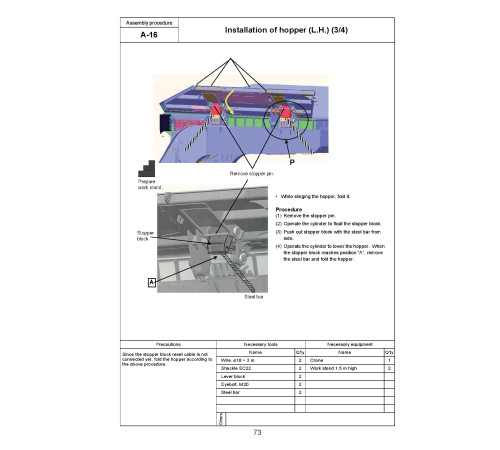

A-16. INSTALLATION OF HOPPER (L.H.)

A-17. INSTALLATION OF HOPPER (REAR)

A-18. INSTALLATION OF HOPPER PINS

A-19. TIGHTENING OF HOPPER MOUNTING BOLTS

A-20. GREASING OF HOPPER

A-21. INSTALLATION OF FIXED HOPPER (IF EQUIPPED)

A-22. INSTALLATION OF CONVEYOR

A-23. INSTALLATION OF CONVEYOR PIPING

A-24. POSTURE OF CONVEYOR

A-25. ADJUSTMENT OF CONVEYOR TENSION

A-26. ADJUSTMENT OF CONVEYOR SNAKING

A-27. ADJUSTMENT OF CONVEYOR SCRAPER

A-28. ADJUSTMENT OF INSTALLATION OF RETURN ROLLER GUARD

A-29. ADJUSTMENT OF MUCK DISCHARGE CONVEYOR SCRAPER (IF EQUIPPED)

A-30. INSTALLATION OF MAGNETIC SEPARATOR ASSEMBLY

A-31. INSTALLATION OF REAR COVER FLOOR

A-32. INSTALLATION OF TAIL PIPE

A-33. INSTALLATION OF ROTARY LAMP AND WORKING LAMP ASSEMBLY

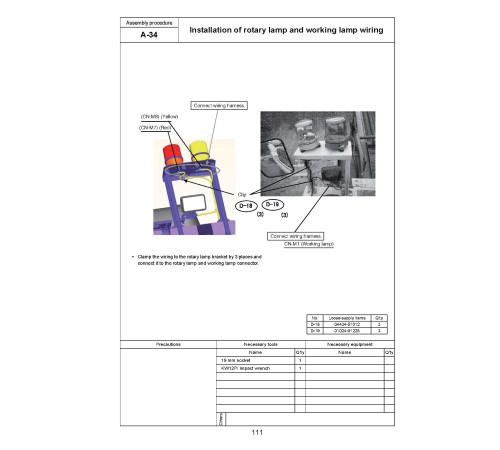

A-34. INSTALLATION OF ROTARY LAMP AND WORKING LAMP WIRING

A-35. ADJUSTMENT OF MIRRORS

A-36. INSTALLATION OF RESERVOIR TANK COVER

A-37. INSTALLATION OF FUEL TANK COVER

M. CHECK AND MAINTENANCE PROCEDURES AFTER COMPLETION OF ASSEMBLY

M-1. CHECK FUEL, COOLANT AND LUBRICANTS

M-2. AIR BLEEDING FROM HYDRAULIC CIRCUITS

M-3. REPLACEMENT OF RETURN FILTER (STANDARD FILTER TO FLUSHING FILTER)

M-4. FLUSHING OF HYDRAULIC CIRCUIT

FIELD ASSEMBLY INSPECTION REPORT

This manual will assist you in for your mobile crusher.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

BR580JG-1 (SN: 01001-)

Format: PDF, 155 pages

Language: English

Table of Contents:

PREFACE

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

OUTLINE OF WORK PROCESS

FLOW OF ASSEMBLY PROCEDURE

KIT LAYOUT DRAWING

PACKING POSTURE FOR TRANSPORTATION

LIST OF TOOLS FOR FIELD ASSEMBLING

TIGHTENING TORQUE

COATING MATERIALS LIST

LIST OF SEPARATELY SHIPPED PARTS

A. ASSEMBLY PROCEDURE

A- 1. PREPARATION FOR INSTALLATION OF CRUSHER ASSEMBLY

A- 2. INSTALLATION OF CRUSHER ASSEMBLY

A- 3. INSTALLATION OF STEPS

A- 4. INSTALLATION OF HANDRAILS

A- 5. INSTALLATION OF FLOOR

A- 6. INSTALLATION OF CRUSHER MOTOR HOSES

A- 7. INSTALLATION OF LOCK CYLINDER HOSES

A- 8. INSTALLATION OF CRUSHER WIRING

A- 9. INSTALLATION OF CRUSHER COVERS

A-10. INSTALLATION OF GUARD ASSEMBLY

A-11. INSTALLATION OF DUST PLATE ASSEMBLY

A-12. INSTALLATION OF SECOND CHUTES

A-13. INSTALLATION OF FEEDER MOTOR

A-14. POSTURE OF OPEN/CLOSE HOPPER

A-15. INSTALLATION OF HOPPER (R.H.)

A-16. INSTALLATION OF HOPPER (L.H.)

A-17. INSTALLATION OF HOPPER (REAR)

A-18. INSTALLATION OF HOPPER PINS

A-19. TIGHTENING OF HOPPER MOUNTING BOLTS

A-20. GREASING OF HOPPER

A-21. INSTALLATION OF FIXED HOPPER (IF EQUIPPED)

A-22. INSTALLATION OF CONVEYOR

A-23. INSTALLATION OF CONVEYOR PIPING

A-24. POSTURE OF CONVEYOR

A-25. ADJUSTMENT OF CONVEYOR TENSION

A-26. ADJUSTMENT OF CONVEYOR SNAKING

A-27. ADJUSTMENT OF CONVEYOR SCRAPER

A-28. ADJUSTMENT OF INSTALLATION OF RETURN ROLLER GUARD

A-29. ADJUSTMENT OF MUCK DISCHARGE CONVEYOR SCRAPER (IF EQUIPPED)

A-30. INSTALLATION OF MAGNETIC SEPARATOR ASSEMBLY

A-31. INSTALLATION OF REAR COVER FLOOR

A-32. INSTALLATION OF TAIL PIPE

A-33. INSTALLATION OF ROTARY LAMP AND WORKING LAMP ASSEMBLY

A-34. INSTALLATION OF ROTARY LAMP AND WORKING LAMP WIRING

A-35. ADJUSTMENT OF MIRRORS

A-36. INSTALLATION OF RESERVOIR TANK COVER

A-37. INSTALLATION OF FUEL TANK COVER

M. CHECK AND MAINTENANCE PROCEDURES AFTER COMPLETION OF ASSEMBLY

M-1. CHECK FUEL, COOLANT AND LUBRICANTS

M-2. AIR BLEEDING FROM HYDRAULIC CIRCUITS

M-3. REPLACEMENT OF RETURN FILTER (STANDARD FILTER TO FLUSHING FILTER)

M-4. FLUSHING OF HYDRAULIC CIRCUIT

FIELD ASSEMBLY INSPECTION REPORT

General

Language

EnglishModel of Truck

BR580JG-1Region

JapanType of Document

Field Assembly ManualType of Truck

Mobile CrusherReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.