$10.00

Language

EnglishModel of Truck

D155AX-6Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler DozerIllustrated factory Field Assembly Manual for Komatsu Crawler Dozers Models D155AX-6.

This manual will assist you in for your crawler dozer.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

D155AX-6 (SN: 80001-)

Format: PDF, 126 pages

Language: English

Table of Contents:

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

ASSEMBLY PROCEDURE, NECESSARY EQUIPMENT, AND SCHEDULE

LAYOUT OF KIT

STYLE FOR TRANSPORTATION

LIST OF TOOLS FOR FIELD ASSEMBLING

TIGHTENING TORQUE

COATING MATERIALS LIST

Selection of wire ropes used for assembly

A. Assembly

A-1. Unloading and installing tractor

A-2. Installing track shoes

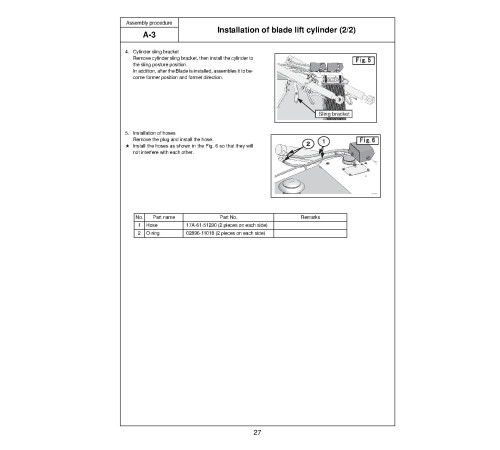

A-3. Installation of blade lift cylinder

A-4. Assembly of blade

A-5. Installation of full roller guard

A-6. Installation of blade

A-7. Installation of ripper assembly

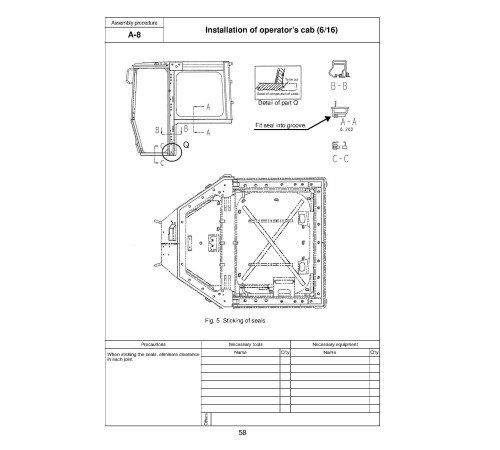

A-8. Installation of operator’s cab

A-9. Check track tension

A-10. Check of oil and coolant levels

A-11. Lubricating

A-12. Bleeding air from hydraulic cylinders

A-13. Installation of additional working lamps

A-14. Installation of KOMTRAX parts

A-15. Installation of KOMTRAX antenna

A-16. Installation of fire extinguisher

M. CHECK AND MAINTENANCE PROCEDURES AFTER COMPLETION OF ASSEMBLY

M-1. Testing and adjusting operator’s cab

M-2. Replacement of return filter (Standard filter to flushing filter)

M-3. Flushing of hydraulic circuit, and bleeding air from hydraulic cylinders (Part 1)

M-4. Replacement of return filter (Flushing filter to standard filter)

M-5. Bleeding air from hydraulic cylinders (Part 2)

FIELD ASSEMBLY INSPECTION REPORT

This manual will assist you in for your crawler dozer.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

D155AX-6 (SN: 80001-)

Format: PDF, 126 pages

Language: English

Table of Contents:

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

ASSEMBLY PROCEDURE, NECESSARY EQUIPMENT, AND SCHEDULE

LAYOUT OF KIT

STYLE FOR TRANSPORTATION

LIST OF TOOLS FOR FIELD ASSEMBLING

TIGHTENING TORQUE

COATING MATERIALS LIST

Selection of wire ropes used for assembly

A. Assembly

A-1. Unloading and installing tractor

A-2. Installing track shoes

A-3. Installation of blade lift cylinder

A-4. Assembly of blade

A-5. Installation of full roller guard

A-6. Installation of blade

A-7. Installation of ripper assembly

A-8. Installation of operator’s cab

A-9. Check track tension

A-10. Check of oil and coolant levels

A-11. Lubricating

A-12. Bleeding air from hydraulic cylinders

A-13. Installation of additional working lamps

A-14. Installation of KOMTRAX parts

A-15. Installation of KOMTRAX antenna

A-16. Installation of fire extinguisher

M. CHECK AND MAINTENANCE PROCEDURES AFTER COMPLETION OF ASSEMBLY

M-1. Testing and adjusting operator’s cab

M-2. Replacement of return filter (Standard filter to flushing filter)

M-3. Flushing of hydraulic circuit, and bleeding air from hydraulic cylinders (Part 1)

M-4. Replacement of return filter (Flushing filter to standard filter)

M-5. Bleeding air from hydraulic cylinders (Part 2)

FIELD ASSEMBLY INSPECTION REPORT

General

Language

EnglishModel of Truck

D155AX-6Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler DozerReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.