$10.00

Language

EnglishModel of Truck

D475A-5, D475ASD-5Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler DozerIllustrated factory Field Assembly Manual for Komatsu Crawler Dozers Models D475A-5 and D475ASD-5.

This manual will assist you in for your crawler dozer.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

D475A-5 (SN: 30001-)

D475ASD-5 (SN: 30001-)

Format: PDF, 244 pages

Language: English

Table of Contents:

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

DISPOSAL OF REMOVED PARTS

ASSEMBLY PROCEDURE, NECESSARY EQUIPMENT, AND SCHEDULE

KIT LAYOUT DIAGRAM

STYLE FOR TRANSPORTATION

TOOLS LIST FOR FIELD ASSEMBLY

SKETCH OF TOOLS

TIGHTENING TORQUE

COATING MATERIALS

A. Assembly

A- 1. Setting of track shoe

A- 2. Setting of the machine

A- 3. Installation of blade lift hydraulic cylinder

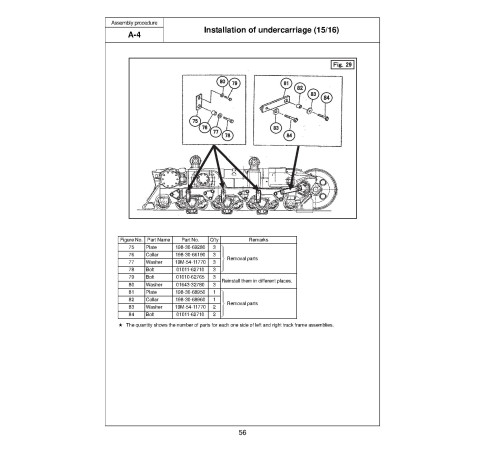

A- 4. Installation of undercarriage

A- 5. Adding oil to pivot chamber

A- 6. Check of oil and coolant levels

A- 7. Installation of ripper

A- 8. Installation of trunnion

A- 9. Installation of track shoe

A-10. Check track tension

A-11. Assembly of blade

A-12. Installation of blade

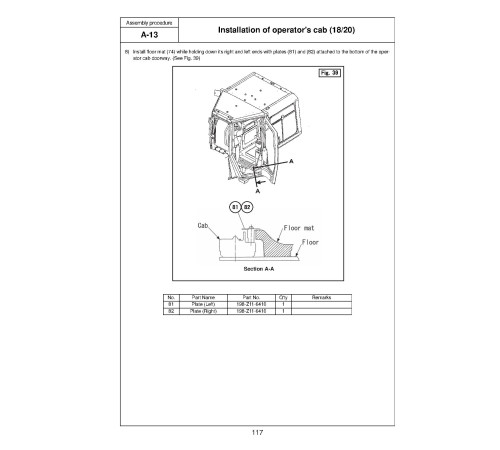

A-13. Installation of operator's cab

A-14. Installation of ROPS

A-15. Installing direction of exhaust pipe

A-16. Installation of giant ripper shank

A-17. Adjustment of arm joint (U-blade)

A-18. Installation of counterweight

A-19. Procedure for adjusting blade tilt angle limit

A-20. Method of checking auto-reset system (Superdozer)

A-21. Installation of ORBCOMM antenna and wiring harness

A-22. Installing lunchbox band (if equipped)

A-23. Greasing each part of work equipment

A-24. Bleeding air from hydraulic cylinders

A-25. Air bleeding from work equipment pump and fan pump

M. CHECK AND MAINTENANCE PROCEDURES AFTER COMPLETION OF ASSEMBLY

M- 1. Check and adjustment of operator’s cab

M- 2. Inspection of machine monitor

M- 3. No-injection cranking of engine

M- 4. Setting procedure of user adjust mode

M- 5. Replacement of return filter (Replacement of standard filter -> special flushing parts)

M- 6. Flushing of hydraulic circuit, and bleeding air from hydraulic cylinders (Part 1)

M- 7. Replacement of return filter (Replacement of special flushing parts -> standard filter)

M- 8. Bleeding air from hydraulic cylinders (Part 2)

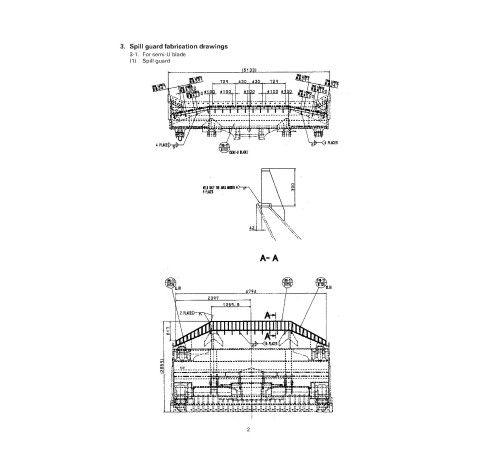

APPENDIX 1. INSTALLATION OF SPILL GUARDS

APPENDIX 2. PRECAUTIONS FOR INITIALIZATION PROCEDURES FOR VHMS CONTROLLER

FIELD ASSEMBLY INSPECTION REPORT (U-DOZER SPECIFICATION)

FIELD ASSEMBLY INSPECTION REPORT (SUPERDOZER SPECIFICATION)

This manual will assist you in for your crawler dozer.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

D475A-5 (SN: 30001-)

D475ASD-5 (SN: 30001-)

Format: PDF, 244 pages

Language: English

Table of Contents:

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

DISPOSAL OF REMOVED PARTS

ASSEMBLY PROCEDURE, NECESSARY EQUIPMENT, AND SCHEDULE

KIT LAYOUT DIAGRAM

STYLE FOR TRANSPORTATION

TOOLS LIST FOR FIELD ASSEMBLY

SKETCH OF TOOLS

TIGHTENING TORQUE

COATING MATERIALS

A. Assembly

A- 1. Setting of track shoe

A- 2. Setting of the machine

A- 3. Installation of blade lift hydraulic cylinder

A- 4. Installation of undercarriage

A- 5. Adding oil to pivot chamber

A- 6. Check of oil and coolant levels

A- 7. Installation of ripper

A- 8. Installation of trunnion

A- 9. Installation of track shoe

A-10. Check track tension

A-11. Assembly of blade

A-12. Installation of blade

A-13. Installation of operator's cab

A-14. Installation of ROPS

A-15. Installing direction of exhaust pipe

A-16. Installation of giant ripper shank

A-17. Adjustment of arm joint (U-blade)

A-18. Installation of counterweight

A-19. Procedure for adjusting blade tilt angle limit

A-20. Method of checking auto-reset system (Superdozer)

A-21. Installation of ORBCOMM antenna and wiring harness

A-22. Installing lunchbox band (if equipped)

A-23. Greasing each part of work equipment

A-24. Bleeding air from hydraulic cylinders

A-25. Air bleeding from work equipment pump and fan pump

M. CHECK AND MAINTENANCE PROCEDURES AFTER COMPLETION OF ASSEMBLY

M- 1. Check and adjustment of operator’s cab

M- 2. Inspection of machine monitor

M- 3. No-injection cranking of engine

M- 4. Setting procedure of user adjust mode

M- 5. Replacement of return filter (Replacement of standard filter -> special flushing parts)

M- 6. Flushing of hydraulic circuit, and bleeding air from hydraulic cylinders (Part 1)

M- 7. Replacement of return filter (Replacement of special flushing parts -> standard filter)

M- 8. Bleeding air from hydraulic cylinders (Part 2)

APPENDIX 1. INSTALLATION OF SPILL GUARDS

APPENDIX 2. PRECAUTIONS FOR INITIALIZATION PROCEDURES FOR VHMS CONTROLLER

FIELD ASSEMBLY INSPECTION REPORT (U-DOZER SPECIFICATION)

FIELD ASSEMBLY INSPECTION REPORT (SUPERDOZER SPECIFICATION)

General

Language

EnglishModel of Truck

D475A-5, D475ASD-5Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler DozerReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.