$10.00

Language

EnglishModel of Truck

D475A-3Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler DozerIllustrated factory Field Assembly Manual for Komatsu Crawler Dozers Models D475A-3.

This manual will assist you in for your crawler dozer.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

D475A-3 (SN: 10601-)

Format: PDF, 155 pages

Language: English

Table of Contents:

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

ASSEMBLY PROCEDURE, NECESSARY EQUIPMENT, AND SCHEDULE

LAYOUT OF KIT

STYLE FOR TRANSPORTATION

TOOLS LIST FOR FIELD ASSEMBLY

TIGHTENING TORQUE

COATING MATERIALS

A. ASSEMBLY PROCEDURE

A-1 INSTALLATION OF UNDERCARRIAGE

A-2 INSTALLATION OF RIPPER

A-3 INSTALLATION OF TRACKS

A-4 ADDING OIL TO PIVOT CHAMBER

A-5 INSTALLATION OF RIPPER SHANK

A-6 INSTALLATION OF BLADE LIFT CYLINDER

A-7 INSTALLATION OF TILT HOSES AND TRUNNION

A-8 ASSEMBLY OF BLADE

A-9 ADJUSTMENT OF ARM JOINT (U-BLADE)

A-10 INSTALLATION OF BLADE

A-11 INSTALLATION OF COUNTERWEIGHT

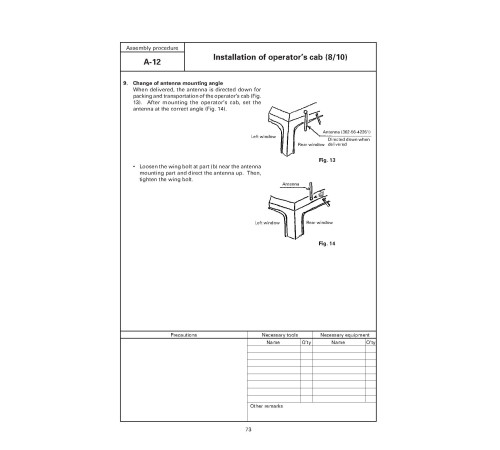

A-12 INSTALLATION OF OPERATOR'S CAB

A-13 INSTALLATION OF ROPS

A-14 ADJUSTMENT OF POTENTIOMETER ROD

A-15 PROCEDURE FOR ADJUSTING BLADE TILT LIMIT ANGLE

A-16 METHOD OF CHECKING AUTO-RESET SYSTEM (SUPERDOZER)

A-17 CHECK TRACK TENSION

A-18 CHECK OF OIL/COOLANT LEVEL IN EACH PART

A-19 GREASING OF GREASING POINT

A-20 INSTALLATION OF ORBCOMM ANTENNA AND WIRING HARNESS

A-21 REPLACEMENT OF RETURN FILTER (REPLACEMENT OF STANDARD FILTER WITH FLUSHING FILTER)

A-22 INSTALLING DIRECTION OF EXHAUST PIPE

A-23 BLEEDING AIR FROM HYDRAULIC CYLINDERS

M. CHECK AND MAINTENANCE PROCEDURES AFTER COMPLETION OF ASSEMBLY

M-1 TESTING AND ADJUSTING OPERATOR'S CAB

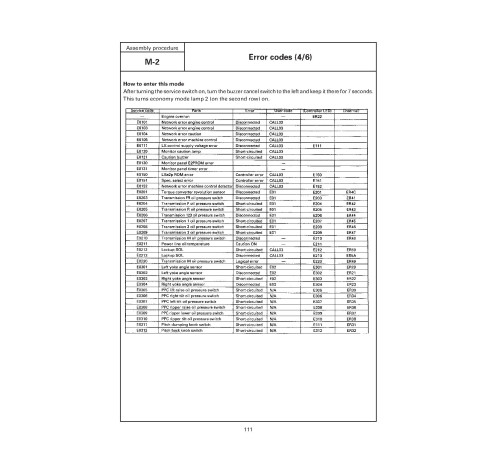

M-2 ERROR CODE

M-3 FLUSHING HYDRAULIC CIRCUIT

INSTALLATION OF SPILL GUARD

1. INTRODUCTION

2. ADDITIONAL PARTS

3. MANUFACUTURE DRAWING FOR SPILL GUARD

4. INSTALLATION PROCEDURE

FIELD ASSEMBLY INSPECTION REPORT [FOR U OR SEMI U TILT DOZER]

FIELD ASSEMBLY INSPECTION REPORT [FOR SUPER DOZER]

This manual will assist you in for your crawler dozer.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

D475A-3 (SN: 10601-)

Format: PDF, 155 pages

Language: English

Table of Contents:

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

ASSEMBLY PROCEDURE, NECESSARY EQUIPMENT, AND SCHEDULE

LAYOUT OF KIT

STYLE FOR TRANSPORTATION

TOOLS LIST FOR FIELD ASSEMBLY

TIGHTENING TORQUE

COATING MATERIALS

A. ASSEMBLY PROCEDURE

A-1 INSTALLATION OF UNDERCARRIAGE

A-2 INSTALLATION OF RIPPER

A-3 INSTALLATION OF TRACKS

A-4 ADDING OIL TO PIVOT CHAMBER

A-5 INSTALLATION OF RIPPER SHANK

A-6 INSTALLATION OF BLADE LIFT CYLINDER

A-7 INSTALLATION OF TILT HOSES AND TRUNNION

A-8 ASSEMBLY OF BLADE

A-9 ADJUSTMENT OF ARM JOINT (U-BLADE)

A-10 INSTALLATION OF BLADE

A-11 INSTALLATION OF COUNTERWEIGHT

A-12 INSTALLATION OF OPERATOR'S CAB

A-13 INSTALLATION OF ROPS

A-14 ADJUSTMENT OF POTENTIOMETER ROD

A-15 PROCEDURE FOR ADJUSTING BLADE TILT LIMIT ANGLE

A-16 METHOD OF CHECKING AUTO-RESET SYSTEM (SUPERDOZER)

A-17 CHECK TRACK TENSION

A-18 CHECK OF OIL/COOLANT LEVEL IN EACH PART

A-19 GREASING OF GREASING POINT

A-20 INSTALLATION OF ORBCOMM ANTENNA AND WIRING HARNESS

A-21 REPLACEMENT OF RETURN FILTER (REPLACEMENT OF STANDARD FILTER WITH FLUSHING FILTER)

A-22 INSTALLING DIRECTION OF EXHAUST PIPE

A-23 BLEEDING AIR FROM HYDRAULIC CYLINDERS

M. CHECK AND MAINTENANCE PROCEDURES AFTER COMPLETION OF ASSEMBLY

M-1 TESTING AND ADJUSTING OPERATOR'S CAB

M-2 ERROR CODE

M-3 FLUSHING HYDRAULIC CIRCUIT

INSTALLATION OF SPILL GUARD

1. INTRODUCTION

2. ADDITIONAL PARTS

3. MANUFACUTURE DRAWING FOR SPILL GUARD

4. INSTALLATION PROCEDURE

FIELD ASSEMBLY INSPECTION REPORT [FOR U OR SEMI U TILT DOZER]

FIELD ASSEMBLY INSPECTION REPORT [FOR SUPER DOZER]

General

Language

EnglishModel of Truck

D475A-3Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler DozerReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.