Model

SEBM0170A07RSKU

41575Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: S6D155-4A, S6D155-4D: SEBE6120A05

$25.00

Language

EnglishModel of Truck

D150A-1, D155A-1Region

WorldWideType of Document

Workshop ManualType of Truck

Crawler DozerIllustrated factory Workshop Manual for Komatsu Crawler Dozers Models D150A-1 and D155A-1.

This manual will assist you in diagnosing, repairing, and adjusting for your crawler dozer.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

D150A-1 (SN: 08408-)

D155A-1 (SN: 15001-)

Format: PDF, 1110 pages

Language: English

Table of Contents:

Safety

How to read the shop manual

Hoisting instructions

Standard tightening torque

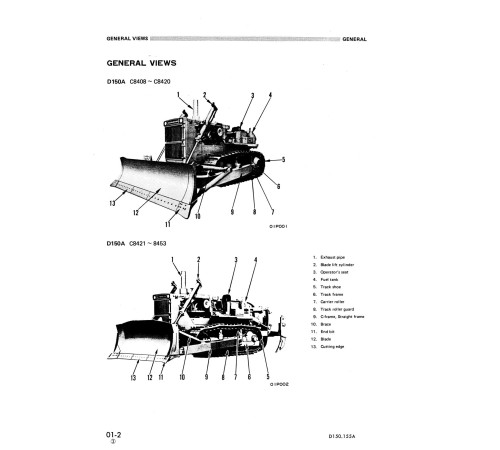

General

Specifications

General assembly drawing

Engine specifications

Weight table

Position of serial numbers (Engine)

Position of serial numbers (body)

Table of oil and coolant

Engine structure and function

Radiator, fan

Oil cooler

P.T.O

Engine control

Fuel piping

Engine Testing and adjusting

Tool list

Trouble shooting criteria

General instructions

Intake ans exhaust system

Engine body

Lubrication system

Fuel system

Engine disassembly and assembly

Dismounting turbocharger

mounting turbocharger

Dismounting engine oil cooler

Mounting engine oil cooler

torque convertor oil cooler

Nozzle holder

Fuel injection pump

Fan belt

Water pump

Starting motor

Alternator

Cylinder head

Fuel tank

Radiator guard

Radiator

Engine

Power traing Structure and functions

General

Main clutch

Inertia brake

Transmisssion D150A

Double mesh preventive device

Torque convertor

Transmission D155A

Torqflow

Transmission lubrication relief vanlve

Transmission control valve

Transmission pump

Bevel gear shaft and steering clutch

Steering and brake piping

steering hydraulic system

Brake hydraulic system

Steering brake and booster D150A AND D155A

Steering brake and booster D155A 25001

Steering control valve d155a 25001

Steering pump

Final drive

power train testing and adjusting

Main clutch hydraulic control

Torqflow hydraulic control

Steering hydraulic control

Brake hydraulic control

Table of oil pressure measuring points

Procedure for measuring oil pressure and temperature

Procedure for measurment of lever and pedal travel

Adjustment procedure for strokes

Adjusting main clutch

Table of maintenance standerds

Power train disassembly and assembly

pto and flywheel

Main clutch

Transmission assembly

Torque convertor

Torque convertor relief valve

Torque converter regulator valve

Torqflow transmission D155 15001 - 25000

Torqflow transmission D155A Sn 25001

Bevel gear and bevel gear shaft

Final drive

Steering control valve

Steering brake interlocking valve

Brake safety valve

Brake booster

Final drive

Torqflow pump

Steering pump

Torque converter oil cooler

Floor frame

Rops cab

Fuel tank

Radiator

Radiator guard

Power Train Maintenance standard

Transmission

Bevel gear shaft and steering system

Final drive

Undercarriage Structure and function

Track

Track group

Recail spring

Idler

Track roller, carrier roller

Suspension

undercarriage Testing and adjusting

indercarriage Disassembly and assembly

track

Carrier roller

Track roller

Idler

Recoil spring

Track frame

Undercarriage maintenance standard

Undercarriage

Hydraulic system structure and function

Hydraulic control

Hydraulic tank

Hydraulic control valve

Ripper selector valve and pilot check valve

Pin puller valve

Pilot valve

Rotary servo valve

Servo valve hydralic control/valve

Safety valve

Cylinders

Piston valve

Hydraulic control

Hydraulic system testing and adjusting

General description

Hydraulic control

Pin puller control

Measurment of oil pressure and temperature

Measurment of operating force

Table of maintance standard

Hydraulic control sysyem Disassembly and assembly

Disassembly and assembly

Hydraulic pump

Hydraulic tank

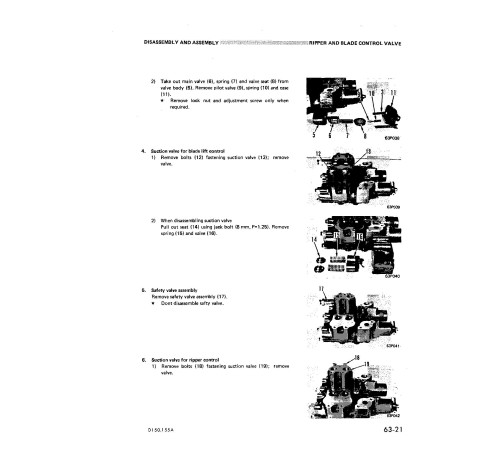

Ripper & blade control valve

Blade tilt control valve

Blade tilt servo valve

Ripper servo valve

Ripper pin puller valve

Ripper selector valve

Blade lift cylinder

Blade tilt cylinder

Ripper lift & Tilt cylinder

Ripper pin puller cylinder

Hydraulic system Maintance standard

Torque specifications for nuts and bolts

Hydraulic control valve

Cylinders

Work equipment structure and function

Multi ripper

Giant ripper

Work equipment testing and adjustment

Straight tilt dozer

work equipment disassembly & assembly

Blade

Ripper

Work equipment Maintenance standard

Torque specifications

Straight tilt dozer

Multi ripper

Giant ripper

Others Electrical system

Electical circuit diagram

Electical wiring diagram

Warning module

Automatic priming system

This manual will assist you in diagnosing, repairing, and adjusting for your crawler dozer.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

D150A-1 (SN: 08408-)

D155A-1 (SN: 15001-)

Format: PDF, 1110 pages

Language: English

Table of Contents:

Safety

How to read the shop manual

Hoisting instructions

Standard tightening torque

General

Specifications

General assembly drawing

Engine specifications

Weight table

Position of serial numbers (Engine)

Position of serial numbers (body)

Table of oil and coolant

Engine structure and function

Radiator, fan

Oil cooler

P.T.O

Engine control

Fuel piping

Engine Testing and adjusting

Tool list

Trouble shooting criteria

General instructions

Intake ans exhaust system

Engine body

Lubrication system

Fuel system

Engine disassembly and assembly

Dismounting turbocharger

mounting turbocharger

Dismounting engine oil cooler

Mounting engine oil cooler

torque convertor oil cooler

Nozzle holder

Fuel injection pump

Fan belt

Water pump

Starting motor

Alternator

Cylinder head

Fuel tank

Radiator guard

Radiator

Engine

Power traing Structure and functions

General

Main clutch

Inertia brake

Transmisssion D150A

Double mesh preventive device

Torque convertor

Transmission D155A

Torqflow

Transmission lubrication relief vanlve

Transmission control valve

Transmission pump

Bevel gear shaft and steering clutch

Steering and brake piping

steering hydraulic system

Brake hydraulic system

Steering brake and booster D150A AND D155A

Steering brake and booster D155A 25001

Steering control valve d155a 25001

Steering pump

Final drive

power train testing and adjusting

Main clutch hydraulic control

Torqflow hydraulic control

Steering hydraulic control

Brake hydraulic control

Table of oil pressure measuring points

Procedure for measuring oil pressure and temperature

Procedure for measurment of lever and pedal travel

Adjustment procedure for strokes

Adjusting main clutch

Table of maintenance standerds

Power train disassembly and assembly

pto and flywheel

Main clutch

Transmission assembly

Torque convertor

Torque convertor relief valve

Torque converter regulator valve

Torqflow transmission D155 15001 - 25000

Torqflow transmission D155A Sn 25001

Bevel gear and bevel gear shaft

Final drive

Steering control valve

Steering brake interlocking valve

Brake safety valve

Brake booster

Final drive

Torqflow pump

Steering pump

Torque converter oil cooler

Floor frame

Rops cab

Fuel tank

Radiator

Radiator guard

Power Train Maintenance standard

Transmission

Bevel gear shaft and steering system

Final drive

Undercarriage Structure and function

Track

Track group

Recail spring

Idler

Track roller, carrier roller

Suspension

undercarriage Testing and adjusting

indercarriage Disassembly and assembly

track

Carrier roller

Track roller

Idler

Recoil spring

Track frame

Undercarriage maintenance standard

Undercarriage

Hydraulic system structure and function

Hydraulic control

Hydraulic tank

Hydraulic control valve

Ripper selector valve and pilot check valve

Pin puller valve

Pilot valve

Rotary servo valve

Servo valve hydralic control/valve

Safety valve

Cylinders

Piston valve

Hydraulic control

Hydraulic system testing and adjusting

General description

Hydraulic control

Pin puller control

Measurment of oil pressure and temperature

Measurment of operating force

Table of maintance standard

Hydraulic control sysyem Disassembly and assembly

Disassembly and assembly

Hydraulic pump

Hydraulic tank

Ripper & blade control valve

Blade tilt control valve

Blade tilt servo valve

Ripper servo valve

Ripper pin puller valve

Ripper selector valve

Blade lift cylinder

Blade tilt cylinder

Ripper lift & Tilt cylinder

Ripper pin puller cylinder

Hydraulic system Maintance standard

Torque specifications for nuts and bolts

Hydraulic control valve

Cylinders

Work equipment structure and function

Multi ripper

Giant ripper

Work equipment testing and adjustment

Straight tilt dozer

work equipment disassembly & assembly

Blade

Ripper

Work equipment Maintenance standard

Torque specifications

Straight tilt dozer

Multi ripper

Giant ripper

Others Electrical system

Electical circuit diagram

Electical wiring diagram

Warning module

Automatic priming system

General

Language

EnglishModel of Truck

D150A-1, D155A-1Region

WorldWideType of Document

Workshop ManualType of Truck

Crawler DozerReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.