$20.00

Language

EnglishModel of Truck

N14Region

WorldWideType of Truck

Diesel EngineWorkshop Manual

1Diagnostic and Repair Manual

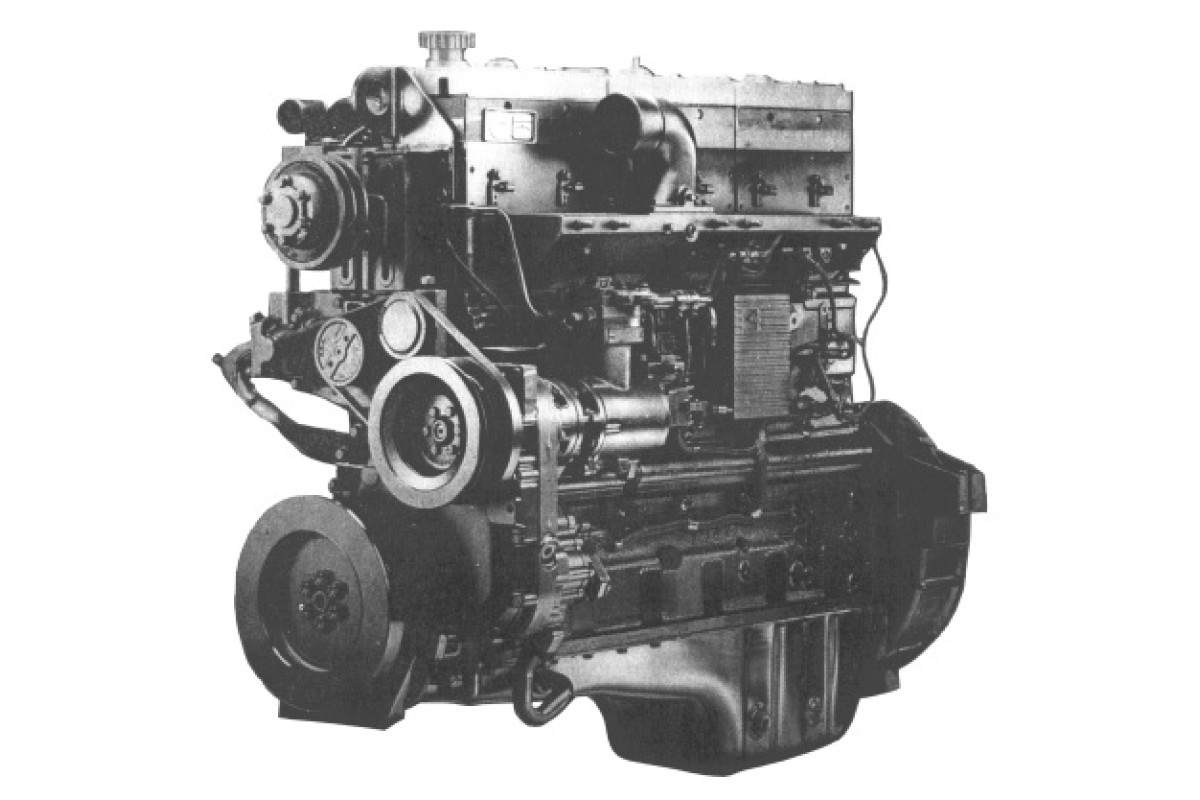

1Illustrated factory set of Service Manuals for Cummins Diesel Engines Models N14.

This manuals will assist you in diagnosing, repairing, adjusting, troubleshooting, assembling, and disassembling for your diesel engine.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

N14

The manual comprises 2 documents, including the Workshop Manual, and Diagnostic and Repair Manual

1. Workshop Manual (3810487)

Format: PDF, 587 pages

Language: English

Table of Contents:

INTRODUCTION

MANUAL ORGANIZATION

GENERAL REPAIR INSTRUCTIONS

GENERAL SAFETY INSTRUCTIONS

SYMBOLS USED IN THIS MANUAL

SIMBOLOS USADOS EN ESTE MANUAL

SYMBOLES UTILISES DANS CE MANUEL

SYMBOLE

ILLUSTRATIONS

GLOSSARY OF TERMS

ENGINE IDENTIFICATION

ENGINE DIAGRAMS

GENERAL CLEANING INSTRUCTIONS

GROUP 0 - ENGINE DISASSEMBLY AND ASSEMBLY

COOLANT - DRAINAGE

ENGINE DISASSEMBLY AND ASSEMBLY - SERVICE TOOLS

ENGINE DISASSEMBLY AND ASSEMBLY - GENERAL INFORMATION

ENGINE - PREPARATION FOR CLEANING

COOLANT FILTER - REMOVAL

LUBRICATING OIL FILTER - REMOVAL

CRANKCASE BREATHER - REMOVAL

TURBOCHARGER - REMOVAL

EXHAUST MANIFOLD - REMOVAL

STARTING MOTOR - REMOVAL

FAN AND FAN SPACER - REMOVAL

ALTERNATOR BELTS - REMOVAL

ALTERNATOR - REMOVAL

ALTERNATOR MOUNTING BRACKET - REMOVAL

LUBRICATING OIL COOLER ASSEMBLY - REMOVAL

COOLANT INLET TRANSFER CONNECTION - REMOVAL

DIPSTICK TUBE AND HOUSING - REMOVAL

PISTON COOLING NOZZLES - REMOVAL

WATER HEADER COVERS - REMOVAL

ENGINE - INSTALLATION ON THE REBUILD STAND

FLYWHEEL - REMOVAL

FLYWHEEL HOUSING - REMOVAL

REAR COVER - REMOVAL

CRANKSHAFT SEAL, REAR - REMOVAL

FAN BELTS - REMOVAL

FAN HUB AND FAN HUB SUPPORT BRACKET - REMOVAL

WATER PUMP BELT - REMOVAL

CELECT™ COOLANT TEMPERATURE SENSOR - REMOVAL

THERMOSTAT HOUSING - REMOVAL

AIR COMPRESSOR COOLANT INLET AND OUTLET TUBES - REMOVAL

WATER PUMP - REMOVAL

ACCESSORY DRIVE PULLEY - REMOVAL

VIBRATION DAMPER - REMOVAL

ENGINE SUPPORT BRACKET, FRONT - REMOVAL

STC EXTERNAL OIL PLUMBING - REMOVAL

STC OIL CONTROL VALVE - REMOVAL

CELECT™ ACTUATOR HARNESS - REMOVAL

CELECT™ SENSOR HARNESS - REMOVAL

CELECT™ ELECTRONIC CONTROL MODULE (ECM) - REMOVAL

CELECT™ AMBIENT AIR PRESSURE SENSOR -REMOVAL

CELECT™ LUBRICATING OIL PRESSURE SENSOR - REMOVAL

CELECT™ ECM COOLING PLATE - REMOVAL

FUEL PUMP - REMOVAL

AIR COMPRESSOR - REMOVAL

ACCESSORY DRIVE - REMOVAL

FUEL TUBING - REMOVAL

CELECT™ ENGINE POSITION SENSOR (EPS) - REMOVAL

LUBRICATING OIL TRANFER TUBE - REMOVAL

LUBRICATING OIL PUMP SIGNAL LINE - REMOVAL

LUBRICATING OIL PUMP - REMOVAL

VISCOSITY SENSOR - REMOVAL

CELECT™ BOOST PRESSURE SENSOR - REMOVAL

CELECT™ INTAKE AIR TEMPERATURE SENSOR - REMOVAL

INTAKE MANIFOLD - REMOVAL

ROCKER HOUSING COVERS - REMOVAL

ENGINE BRAKES - REMOVAL

ROCKER LEVER SHAFT ASSEMBLIES - REMOVAL

VALVE CROSSHEADS - REMOVAL

PUSH TUBES - REMOVAL

INJECTORS - REMOVAL

ROCKER LEVER HOUSING - REMOVAL

FUEL CROSSOVERS - REMOVAL

CYLINDER HEADS - REMOVAL

CAM FOLLOWER ASSEMBLIES - REMOVAL

CAMSHAFT BEARING SUPPORT - REMOVAL

LUBRICATING OIL PAN - REMOVAL

GEAR COVER - REMOVAL

CRANKSHAFT SEAL, FRONT - REMOVAL

ACCESSORY DRIVE SEAL - REMOVAL

CAMSHAFT - REMOVAL

PISTON AND CONNECTING ROD ASSEMBLIES - REMOVAL

CYLINDER LINERS - REMOVAL

CRANKSHAFT - REMOVAL

CYLINDER BLOCK - REMOVAL FROM THE REBUILD STAND

CYLINDER BLOCK - INSTALLATION ON THE REBUILD STAND

CRANKSHAFT - INSTALLATION

CYLINDERS LINERS - INSTALLATION

PISTON AND CONNECTING ROD ASSEMBLIES - ASSEMBLY AND INSTALLATION

REAR COVER - INSTALLATION

CRANKSHAFT SEAL, REAR - INSTALLATION

FLYWHEEL HOUSING - INSTALLATION

FLYWHEEL - INSTALLATION

CYLINDER HEADS - INSTALLATION

CAMSHAFT INSTALLATION

CAM FOLLOWER ASSEMBLIES - INSTALLATION

INJECTION TIMING - GENERAL INFORMATION

ACCESSORY DRIVE - INSTALLATION

CELECT™ ENGINE POSITION SENSOR (EPS) - INSTALLATION

LUBRICATING OIL PUMP - INSTALLATION

GEAR COVER - INSTALLATION

CRANKSHAFT SEAL, FRONT - INSTALLATION

CAMSHAFT BEARING SUPPORT - INSTALLATION

ACCESSORY DRIVE SEAL - INSTALLATION

ACCESSORY DRIVE PULLEY - INSTALLATION

LUBRICATING OIL PAN - INSTALLATION

FUEL CROSSOVERS - INSTALLATION

ROCKER LEVER HOUSING - INSTALLATION

INJECTORS - INSTALLATION

PUSH TUBES - INSTALLATION

VALVE CROSSHEADS - INSTALLATION

ROCKER LEVER SHAFT ASSEMBLIES - INSTALLATION

INJECTOR AND VALVE ADJUSTMENT

ENGINE BRAKE - INSTALLATION

ENGINE BRAKE ADJUSTMENT

ROCKER HOUSING COVERS - INSTALLATION

INTAKE MANIFOLD - INSTALLATION

CELECT™ INTAKE AIR TEMPERATURE SENSOR - INSTALLATION

CELECT™ BOOST PRESSURE SENSOR - INSTALLATION

VISCOSITY SENSOR - INSTALLATION

LUBRICATING OIL PUMP SIGNAL - INSTALLATION

LUBRICATING OIL TRANSFER TUBE - INSTALLATION

FUEL TUBING - INSTALLATION

AIR COMPRESSOR - INSTALLATION

FUEL PUMP - INSTALLATION

CELECT™ ECM COOLING PLATE - INSTALLATION

CELECT™ LUBRICATING OIL PRESSURE SENSOR - INSTALLATION

CELECT™ AMBIENT AIR PRESSURE SENSOR - INSTALLATION

CELECT™ ELECTRONIC CONTROL MODULE (ecm) - INSTALLATION

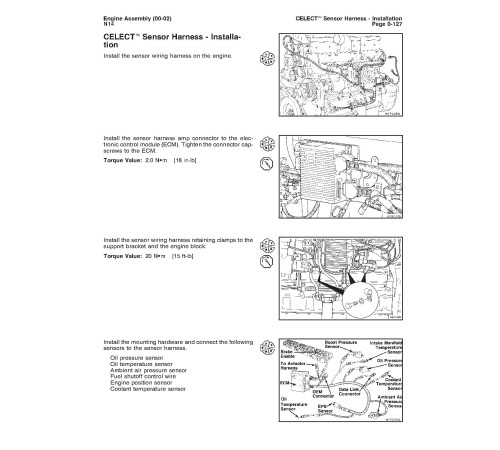

CELECT™ SENSOR HARNESS - INSTALLATION

CELECT™ ACTUATOR HARNESS - INSTALLATION

STC OIL CONTROL VALVE - INSTALLATION

STC EXTERNAL OIL PLUMBING - INSTALLATIONing - Installa-tion

ENGINE SUPPORT BRACKET, FRONT - INSTALLATION

VIBRATION DAMPER - INSTALLATION

WATER PUMP - INSTALLATION

WATER PUMP BELT - INSTALLATION AND ADJUSTMENT

THERMOSTAT HOUSING - INSTALLATION

CELECT™ COOLANT TEMPERATURE SENSOR - INSTALLATION

AIR COMPRESSOR COOLANT INLET AND OUTLET TUBES - INSTALLATION

FAN HUB AND FAN HUB SUPPORT - INSTALLATION

FAN BELTS - INSTALLATION AND ADJUSTMENT

ENGINE - REMOVAL FROM THE REBUILD STAND

PISTON COOLING NOZZLES - INSTALLATION

DIPSTICK TUBE AND HOUSING - INSTALLATION

WATER HEADER COVERS - INSTALLATION

COOLANT INLET TRANSFER CONNECTION - INSTALLATION

LUBRICATING OIL COOLER ASSEMBLY - INSTALLATION

ALTERNATOR MOUNTING BRACKET - INSTALLATION

ALTERNATOR - INSTALLATION

ALTERNATOR BELTS - INSTALLATION AND ADJUSTMENT

FAN AND FAN SPACER - INSTALLATION

STARTING MOTOR - INSTALLATION

EXHAUST MANIFOLD - INSTALLATION

TURBOCHARGER - INSTALLATION

CRANKCASE BREATHER TUBE - INSTALLATION

LUBRICATING OIL FILTER - INSTALLATION

COOLANT FILTER - INSTALLATION

ENGINE - COVERING ALL OPENINGS

GROUP 1 - CYLINDER BLOCK

CYLINDER BLOCK - SERVICE TOOLS

CYLINDER BLOCK - EXPLODED VIEW

CYLINDER BLOCK - GENERAL INFORMATION

CYLINDER BLOCK - DISASSEMBLY

CYLINDER BLOCK - CEANING AND INPECTION

CYLINDER BLOCK - MACHINING

CYLINDER BLOCK COUNTERBORE - INSPECTION AND MACHINING

CYLINDER BLOCK - ASSEMBLY

CYLINDER LINERS - CLEANING AND INSPECTION

PISTONS - CLEANING AND INSPECTION

CONNECTING ROD ASSEMBLIES - CLEANING AND INSPECTION

CONNECTING RODS - BEND AND TWIST INSPECTION

CONNECTING ROD BEARINGS - CLEANING AND INSPECTION

CRANKSHAFT ADAPTER - CLEANING AND INSPECTION

CRANKSHAFT PULLEY - CLEANING AND INSPECTION

VIBRATION DAMPER - CLEANING AND INSPECTION

CRANKSHAFT - CLEANING AND INSPECTION

CRANKSHAFT GEAR - REPLACEMENT

CRANKSHAFT BEARINGS - CLEANING AND INSPECTION

CAMSHAFT - CLEANING AND INSPECTION

CAMSHAFT GEAR - REPLACEMENT

GEAR COVER - CLEANING AND INSPECTION

REAR COVER - CLEANING AND INSPECTION

MAGNETIC CRACK INSPECTION

GROUP 2 - CYLINDER HEAD

CYLINDER HEAD - SERVICE TOOLS

CYLINDER HEA D - EXPLODED VIEW

CYLINDER HEAD - GENERAL INFORMATION

CYLINDER HEAD - CLEANING AND INSPECTION FOR REUSE

CYLINDER HEAD - REBUILD

CYLINDER HEAD - REPLACING THE VALVE GUIDES

CYLINDER HEAD - RING DOWEL REPLACEMENT

CYLINDER HEAD - REPLACING THE VALVE SEAT INSERTS

CYLINDER HEAD - GRINDING THE VALVES

CYLINDER HEAD - REPLACING THE INJECTOR SLEEVES

CYLINDER HEAD - PRESSURE TESTING

CYLINDER HEAD - MAGNETIC PARTICLE CHECKING

CYLINDER HEAD - VACUUM TESTING VALVE SEATING FOR REUSE

CYLINDER HEAD - VALVES - MAGNETIC CRACK INSPECTION

VALVE CROSSHEAD - CLEANING AND CHECKING FOR REUSE

VALVE CROSSHEAD - MAGNETIC CRACK INSPECTION

GROUP 3 - ROCKER LEVER HOUSING ASSEMBLY

ROCKER LEVER HOUSING ASSEMBLY - SERVICE TOOLS

ROCKER LEVER HOUSING COVER - EXPLODED VIEW

ROCKER LEVER HOUSING ASSEMBLY - EXPLODED VIEW

WATER MANIFOLD PLUMBING - EXPLODED VIEW

ROCKER LEVER HOUSING ASSEMBLY - GENERAL INFORMATION

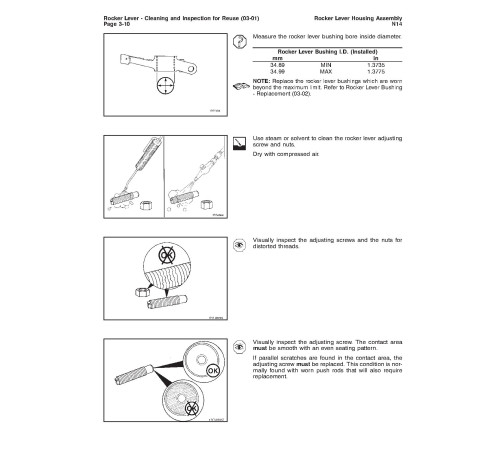

ROCKER LEVER - CLEANING AND INSPECTION FOR REUSE

ROCKER LEVER BUSHING - REPLACEMENT

ROCKER LEVER - MAGNETIC CRACK INSPECTION

ROCKER HOUSING COVERS - CLEANING AND INSPECTION FOR REUSE

ROCKER LEVER HOUSING ASSEMBLY - CLEANING AND INSPECTION FOR REUSE

STC OIL PLUMBING - CLEANING AND INSPECTION FOR REUSE

RING AND PIN DOWEL - REPLACEMENT

METRI-PACK PASS THROUGH CONNECTOR - REPLACEMENT

GROUP 4 - CAM FOLLOWER ASSEMBLY

CAM FOLLOWER ASSEMBLY - SERVICE TOOLS

CAM FOLLOWER ASSEMBLY - EXPLODED VIEW

CAM FOLLOWER ASSEMBLY - GENERAL INFORMATION

CAM FOLLOWER ASSEMBLY - CLEANING AND INSPECTION FOR REUSE

CAM FOLLOWER ASSEMBLY - REBUILD

CAM FOLLOWER LEVER - ROLLER REPLACEMENT

CAM FOLLOWER SOCKET - REPLACEMENT

PUSH ROD - CLEANING AND INSPECTION FOR REUSE

GROUP 5 - FUEL SYSTEM

FUEL PUMP - GENERAL INFORMATION

FUEL PUMP - CLEANING AND INSPECTION FOR REUSE

FUEL PUMP - REBUILD

FUEL PUMP - CALIBRATION

GROUP 6 - INJECTORS AND FUEL LINES

INJECTOR - PT (TYPE D) STEP TIMING CONTROL - EXPLODED VIEW

INJECTOR - CELECT - EXPLODED VIEW

INJECTORS - PT (TYPE D) STEP TIMING CONTROL (STC) GENERAL INFORMATION

INJECTORS - CELECT - GENERAL INFORMATION

STEP TIMING CONTROL (STC) OIL CONTROL VALVE - GENERAL INFORMATION

INJECTORS - CLEANING THE EXTERIOR AND INSPECTION FOR REUSE

INJECTORS - REBUILD

INJECTORS - CALIBRATION

STC OIL CONTROL VALVE - CLEANING

FUEL TUBES, FITTINGS, AND MOUNTING PARTS - CLEANING AND INSPECTION FOR REUSE

GROUP 7 - LUBRICATING OIL SYSTEM

LUBRICATING OIL SYSTEM - SERVICE TOOLS

LUBRICATING OIL SYSTEM - EXPLODED VIEW

LUBRICATING OIL PUMP ASSEMBLY - EXPLODED VIEW

LUBRICATING OIL COOLER - EXPLODED VIEW

LUBRICATING OIL SYSTEM - GENERAL INFORMATION

LUBRICATING OIL PAN - CLEANING AND INSPECTION FOR REUSE

LUBRICATING OIL TRANSFER TUBE - CLEANING AND INSPECTION FOR REUSE

LUBRICATING OIL DIPSTICK AND DIPSTICK TUBE - CLEANING AND INSPECTION FOR REUSE

LUBRICATING OIL DIPSTICK - CALIBRATION

LUBRICATING OIL PUMP - CLEANING AND INSPECTION FOR REUSE

LUBRICATING OIL PUMP - REBUILD

LUBRICATING OIL PUMP BODY AND COVER BUSHING - REPLACEMENT

LUBRICATING OIL PUMP DRIVEN GEAR BUSHING - REPLACEMENT

LUBRICATING OIL PUMP DRIVE GEAR OR SHAFT - REPLACEMENT

LUBRICATING OIL PUMP DRIVEN SHAFT - REPLACEMENT

LUBRICATING OIL COOLER ASSEMBLY REBUILD

GROUP 8 - COOLING SYSTEM

COOLING SYSTEM - SERVICE TOOLS

N14 WATER PUMP AND IDLER ASSEMBLY - EXPLODED VIEW

WATER PUMP AND IDLER ASSEMBLY - GENERAL INFORMATION

WATER PUMP ASSEMBLY

WATER PUMP ASSEMBLY - REBUILD

WATER PUMP IDLER ASSEMBLY - CLEANING AND INSPECTION

WATER PUMP IDLER ASSEMBLY - REBUILD

THERMOSTAT HOUSING - CLEANING AND INSPECTION

COOLANT FILTER HEAD INSERT

COOLANT FILTER SHUTOFF VALVE

FAN - CLEANING AND INSPECTION

WATER TRANSFER TUBES - CLEANING AND INSPECTION

GROUP 9 - DRIVE UNITS

DRIVE UNITS - SERVICE TOOLS

ACCESSORY DRIVE - EXPLODED VIEW

DRIVE UNITS - GENERAL INFORMATION

ACCESSORY DRIVE - CLEANING AND INSPECTION FOR REUSE

ACCESSORY DRIVE - REBUILD

ACCESSORY DRIVE GEAR - REPLACEMENT

ACCESSORY DRIVE PULLEY - CLEANING AND INSPECTION FOR REUSE

ACCESSORY DRIVE PULLEY WEAR SLEEVE - REPLACEMENT

GROUP 10 - INTAKE AIR SYSTEM

SERVICE TOOLS

INTAKE AIR SYSTEM - EXPLODED VIEW

INTAKE AIR SYSTEM - GENERAL INFORMATION

TURBOCHARGER - CLEANING AND INSPECTION

TURBOCHARGER SHAFT AXIAL CLEARANCE CHECKING

TURBOCHARGER BEARING RADIAL CLEARANCE - CHECKING

INTAKE AIR PIPING - ELBOWS

INTAKE MANIFOLD - CLEANING AND INSPECTION

GROUP 11 - EXHAUST SYSTEM

EXHAUST SYSTEM - EXPLODED VIEW

EXHAUST SYSTEM - GENERAL INFORMATION

EXHAUST MANIFOLD - CLEANING AND INSPECTION FOR REUSE

EXHAUST MANIFOLD TURBOCHARGER MOUNTING STUD - REPLACEMENT (11-02)

GROUP 12 - AIR EQUIPMENT

AIR EQUIPMENT - GENERAL INFORMATION

AIR COMPRESSOR - CLEANING AND INSPECTION FOR REUSE

GROUP 13 - ELECTRICAL EQUIPMENT

ELECTRICAL EQUIPMENT - GENERAL INFORMATION

ALTERNATOR BRACKET - CLEANING AND INSPECTION FOR REUSE

ALTERNATOR ADJUSTING LINK - CLEANING AND INSPECTION FOR REUSE

STARTING MOTOR - CLEANING AND INSPECTION FOR REUSE

GROUP 14 - ENGINE TESTING

GENERAL INFORMATION

DEFINITION OF TERMS ON ENGINE PERFORMANCE CURVE

GENERAL RUN-IN PROCEDURES

GENERAL ENGINE TEST/RUN-IN SPECIFICATIONS

ENGINE TESTING - SERVICE TOOLS

ENGINE DYNAMOMETER - INSTALL ENGINE

PRIMING THE LUBRICATING OIL AND FUEL SYSTEMS

ENGINE RUN-IN PROCEDURE - ENGINE DYNAMOMETER

CHASSIS DYNAMOMETER OPERATION

GENERAL TEST PROCEDURE - CHASSIS DYNAMOMETER

ENGINE RUN-IN PROCEDURE - CHASSIS DYNAMOMETER

ENGINE RUN-IN PROCEDURE WITHOUT DYNAMOMETER

ENGINE PAINTING

ENGINE STORAGE - SHORT TERM

ENGINE STORAGE - LONG TERM

GROUP 15 - INSTRUMENTS AND CONTROLS

INSTRUMENTS AND CONTROLS - GENERAL INFORMATION

GROUP 16 - MOUNTING ADAPTATIONS

MOUNTING ADAPTATIONS

FLYWHEEL

FLYWHEEL RING GEAR

FLYWHEEL HOUSING - CLEANING AND INSPECTION FOR REUSE

FRONT ENGINE SUPPORT BRACKET - CLEANING AND INSPECTION FOR REUSE

GROUP 18 - SPECIFICATIONS

GENERAL ENGINE SPECIFICATIONS

CAPSCREW MARKINGS AND TORQUE VALUES

PIPE PLUG TORQUE VALUES

DECIMAL AND METRIC EQUIVALENTS

SPECIFICATIONS - GENERAL INFORMATION

ENGINE ASSEMBLY

CYLINDER BLOCK

CYLINDER HEAD

ROCKER LEVER HOUSING ASEMBLY

CAM FOLLOWER ASSEMBLY

FUEL PUMP - REBUILD SPECIFICATIONS

INJECTORS - REBUILD SPECIFICATIONS

LUBRICATING OIL SYSTEM

LUBRICATING OIL PUMP - INSPECTION SPECIFICATIONS

WATER PUMP ASSEMBLY - REBUILD SPECIFICATIONS

FAN HUB - INSPECTION SPECIFICATIONS

THERMOSTAT HOUSING ASSEMBLY - REBUILD SPECIFICATIONS

THERMOSTAT (RESERVE FLOW COOLING) - OPERATING TEMPERATURE

COOLING SYSTEM - TORQUE VALUES

FUEL PUMP AND COMPRESSOR DRIVE

TURBOCHARGER - INSPECTION SPECIFICATIONS

AIR COMPRESSOR - INSPECTION SPECIFICATIONS

ENGINE TESTING - TEST SPECIFICATIONS

VEHICLE BRAKING - REBUILD SPECIFICATIONS

GROUP 20 - VEHICLE BRAKING

VEHICLE BRAKING - GENERAL INFORMATION

COMPONENTS MANUFACTURERS: NAMES AND ADDRESSES

SERVICE LITERATURE

ADDITIONAL SERVICE LITERATURE

SERVICE LITERATURE ORDERING LOCATION

SERVICE PUBLICATIONS ORDER FORM

INDEX

LITERATURE SURVEY FORM

2. Diagnostic and Repair Manual (3810456)

Format: PDF, 812 pages

Language: English

Table of Contents:

SECTION I - INTRODUCTION

ABOUT THE MANUAL

HOW TO USE THE MANUAL

SYMBOLS

SIMBOLOS

SYMBOLE

SYMBOLES

ILLUSTRATIONS

GENERAL SAFETY INSTRUCTIONS

GENERAL REPAIR INSTRUCTIONS

GENERAL CLEANING INSTRUCTIONS

DEFINITION OF TERMS

SECTION E - ENGINE IDENTIFICATION

CUMMINS MODEL NAME

ENGINE DATAPLATE

FUEL PUMP DATAPLATE

ENGINE SPECIFICATIONS

ENGINE DIAGRAMS

SECTION T - TROUBLESHOOTING

PROCEDURES AND TECHNIQUES

TROUBLESHOOTING SYMPTOMS CHART

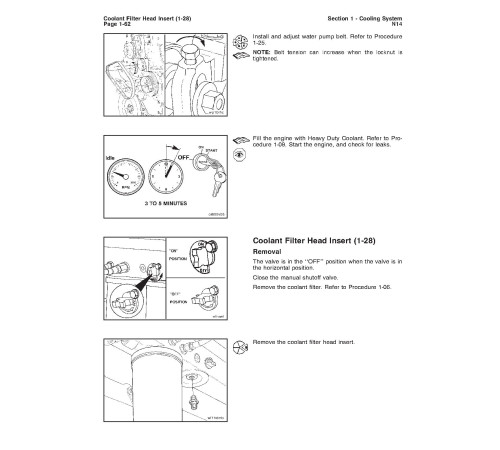

SECTION 1 - COOLING SYSTEM

COOLING SYSTEM GENERAL INFORMATION

COOLANT FLOW DIAGRAM

COOLING SYSTEM SPECIFICATIONS

THERMAL CONTROL SETTINGS

HEAVY DUTY COOLANT

SUPPLEMENTAL COOLANT ADDITIVES (SCA'S)

COOLING SYSTEM SERVICE TOOLS

COOLING SYSTEM WATER

ANTIFREEZE

COOLING SYSTEM SEALING ADDITIVES

COOLING SYSTEM SOLUBLE OILS

COOLANT ADDITIVE REQUIREMENT

COOLANT FILTER

DRAINING THE COOLING SYSTEM

CLEANING THE COOLING SYSTEM

FILLING THE COOLING SYSTEM

COOLING SYSTEM - TESTING FOR AIR OR COMBUSTION GASES

COOLING SYSTEM PRESSURE TESTING

HOSES - INSPECTION

COOLANT TEMPERATURE GAUGE - CHECKING

VENTING THE COOLING SYSTEM

RADIATOR PRESSURE CAP

RADIATOR AND CHARGE AIR COOLED FINS

RADIATOR SHUTTER OPERATION

FAN INSPECTION

FAN SHROUD INSPECTION

FAN SPACER AND PULLEY INSPECTION

FAN BELTS

FAN AND FAN HUB

VISCOUS FAN CLUTCH

ON-OFF THERMATIC FAN CLUTCH

WATER PUMP BELTS

WATER PUMP IDLER PULLEY

WATER PUMP

COOLANT FILTER HEAD INSERT

COOLANT FILTER SHUTOFF VALVE

THERMOSTAT HOUSING

THERMOSTAT SEAL

THERMOSTAT

SECTION 2 - LUBRICATING SYSTEM

LUBRICATING SYSTEM GENERAL INFORMATON

LUBRICATING OIL SYSTEM FLOW DIAGRAM

LUBRICATING OIL SYSTEM FLOW DIAGRAM

LUBRICATING OIL SYSTEM FLOW DIAGRAM - VISCOSITY SENSOR AND STC VALVE

LUBRICATING OIL SYSTEM SPECIFICATIONS

LUBRICATING OIL SYSTEM SERVICE TOOLS

LUBRICATING OIL SYSTEM DIAGNOSTIC CHECKING

LUBRICATING OIL AND FILTER ANALYSIS

LUBRICATING OIL FILTER

LUBRICATING OIL LEAKS

CRANKCASE BREATHER

DRAINING THE LUBRICATING OIL SYSTEM

FILLING THE LUBRICATING OIL SYSTEM

PRIMING THE LUBRICATING OIL SYSTEM

DIPSTICK TUBE AND HOUSING

DIPSTICK CALIBRATION

LUBRICATING OIL TRANSFER TUBE

LUBRICATING OIL PAN

LUBRICATING OIL PUMP

HIGH LUBRICATING OIL PRESSURE RELIEF VALVE

MAIN LUBRICATING OIL PRESSURE REGULATOR

LUBRICATING OIL PUMP SIGNAL LINE

LUBRICATING OIL PUMP SIGNAL LINE ORIFICE (IN CHASSIS)

VISCOSITY SENSOR - STC ENGINES

LUBRICATING OIL COOLER ASSEMBLY

PISTON COOLING NOZZLES

LUBRICATING OIL PRESSURE GAUGE

LUBRICATING OIL TEMPERATURE GAUGE

SECTION 3 - COMBUSTION AIR SYSTEM

COMBUSTION AIR SYSTEM GENERAL INFORMATION

AIR INTAKE SYSTEM FLOW DIAGRAM

EXHAUST SYSTEM FLOW DIAGRAM

COMBUSTION AIR SYSTEM SPECIFICATIONS

COMBUSTION AIR SYSTEM SERVICE TOOLS

AIR LEAKS - TESTING

TURBOCHARGER SEAL LEAK - TESTING

TURBOCHARGER - VERIFYING CORRECT PART NUMBER

INTAKE AIR RESTRICTION

EXHAUST RESTRICTION

TURBOCHARGER BLADE DAMAGE

TURBOCHARGER AXIAL AND RADIAL CLEARANCE

TURBOCHARGER REPLACEMENT

EXHAUST MANIFOLD

INTAKE MANIFOLD

CHARGE AIR COOLER

SECTION 4 - COMPRESSED AIR SYSTEM

COMPRESSED AIR SYSTEM GENERAL INFORMATION

COMPRESSED AIR SYSTEM FLOW DIAGRAMS

COMPRESSED AIR SYSTEM SPECIFICATIONS

COMPRESSED AIR SYSTEM SERVICE TOOLS

CARBON BUILDUP, AIR COMPRESSOR

GASKET LEAKS, AIR COMPRESSOR

COMPRESSOR UNLOADER VALVE

AIR GOVERNOR (AIR COMPRESSOR WILL NOT PUMP)

AIR GOVERNOR

AIR COMPRESSOR, CYLINDER HEAD

AIR COMPRESSOR

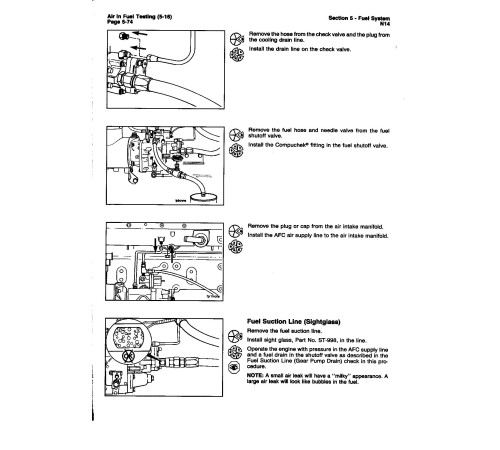

SECTION 5 - FUEL SYSTEM

FUEL SYSTEM GENERAL INFORMATION

FUEL SYSTEM FLOW DIAGRAMS

FUEL SYSTEM SPECIFICATIONS

FUEL SYSTEM - SERVICE TOOLS

FUEL SYSTEM MISCELLANEOUS INFORMATION

FUEL SYSTEM MAINTENANCE

FUEL PUMP

FUEL PUMP FLOW CHECKING, ROTATION AND PRIMING

FUEL PUMP SHUTOFF VALVE

FUEL PUMP ON-ENGINE ADJUSTMENT

AIR ACTUATED ROAD SPEED GOVERNOR

VS THROTTLE SHAFT

VS GOVERNOR ADJUSTING SCREW SEALING JAM NUTS

VS GOVERNOR IDLE SPRING

FUEL GEAR PUMP CHECK VALVE

INJECTORS

STC OIL CONTROL VALVE

STC OIL DELIVERY SYSTEM DIAGNOSTIC TESTING

STC OIL DELIVERY SYSTEM BLOCKAGE - OIL RIFLE TO OIL MANIFOLD

STC OIL DELIVERY SYSTEM BLOCKAGE/LEAKAGE - OIL MANIFOLD TO INJECTORS

CYLINDER MISFIRING/SMOKING LOCATION

AIR IN FUEL TESTING

LUBRICATING OIL DILUTION BY FUEL TESTING

FUEL PUMP INLET RESTRICTION

FUEL PUMP DRAIN LINE RESTRICTION

AFC NO-AIR CHECK

POWER CHECK

FUEL CONSUMPTION CHECK

THROTTLE RESPONSE TEST

STALL SPEED TESTING

OPERATING IN NORMAL TIMING

STALL SPEED CHECK LIST

VE/VMS - ROAD TEST - THROTTLE RESPONSE TEST WORKSHEET

SECTION 6 - ELECTRICAL SYSTEM

ELECTRICAL SYSTEM GENERAL INFORMATION

STARTING SYSTEM SPECIFICATIONS

ELECTRICAL SYSTEM SERVICE TOOLS

BATTERIES

BATTERY CABLES AND CONNECTIONS

STARTER CONNECTIONS

ALTERNATOR BELT

ALTERNATOR REPLACEMENT

STARTING MOTOR REPLACEMENT

SECTION 7 - BASE ENGINE COMPONENTS

BASE ENGINE COMPONENTS GENERAL INFORMATION

BASE ENGINE COMPONENTS SERVICE TOOLS

ROCKER HOUSING COVERS

ENGINE LIFTING BRACKETS

ENGINE LIFTING BRACKET - SERVICE BRACKET

OVERHEAD ADJUSTMENT

ENGINE BRAKE ADJUSTMENT

ENGINE BRAKE REPLACE

PUSH RODS REPLACE

STC OIL PLUMBING

ROCKER LEVERS REPLACE

ROCKER LEVER HOUSINGS REPLACEMENT

CYLINDER BLOCK COUNTERBORE LEAK

CYLINDER BLOCK DECK SURFACE

CYLINDER BLOCK COUNTERBORE - LEAK TESTING

CYLINDER HEAD CAPSCREW HOLES

CYLINDER HEAD CAPSCREW HOLE

CYLINDER LINER PROTRUSION

CYLINDER HEAD GASKET(S) REPLACEMENT

CYLINDER HEADS REPLACE

CYLINDER HEAD PRESSURE TESTING

CAM FOLLOWERS REPLACE

INJECTION TIMING (GENERAL INFORMATION)

INJECTION TIMING

MAIN AND THRUST BEARINGS REPLACE

CONNECTING ROD BEARINGS REPLACEMENT

PISTONS AND RINGS REPLACEMENT

CONNECTING RODS REPLACEMENT

CYLINDER LINERS REPLACEMENT

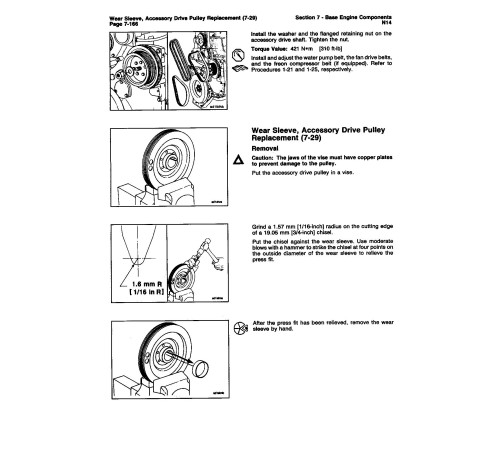

ACCESSORY DRIVE PULLEY REPLACEMENT

WEAR SLEEVE, ACCESSORY DRIVE PULLEY REPLACEMENT

SEAL, ACCESSORY DRIVE REPLACEMENT

ACCESSORY DRIVE REPLACEMENT

VIBRATION DAMPER

CRANKSHAFT PULLEY REPLACEMENT

SEAL, FRONT CRANKSHAFT REPLACEMENT

CAMSHAFT BEARING SUPPORT REPLACEMENT

FRONT ENGINE SUPPORT BRACKET REPLACEMENT

GEAR COVER REPLACEMENT

CRANKSHAFT GEAR REPLACEMENT

CAMSHAFT REPLACEMENT

CAMSHAFT GEAR REPLACEMENT

CAMSHAFT BUSHING REPLACEMENT

FLYWHEEL REPLACEMENT

SEAL, REAR CRANKSHAFT REPLACEMENT

FLYWHEEL HOUSING REPLACEMENT

FLYWHEEL HOUSING REDOWEL TO CYLINDER BLOCK

STRAIGHT THREAD PLUGS, PIPE PLUGS AND CUP PLUGS REPLACEMENT

SECTION 8 - ENGINE TESTING

ENGINE TESTING GENERAL INFORMATION

DEFINITIONS OF TERMS ON ENGINE PERFORMANCE CURVE

GENERAL RUN-IN PROCEDURES

GENERAL ENGINE TEST/RUN-IN SPECIFICATIONS

ENGINE TESTING - SERVICE TOOLS

ENGINE DYNAMOMETER - INSTALL ENGINE

FUEL FLOW MEASUREMENT ON ENGINE OR CHASSIS DYNAMOMETER

INTAKE MANIFOLD BOOST PRESSURE CORRECTION FACTORS

ENGINE RUN-IN PROCEDURE - ENGINE DYNAMOMETER

DYNAMOMETER WORKSHEET

CHASSIS DYNAMOMETER OPERATION

GENERAL TEST PROCEDURE - CHASSIS DYNAMOMETER

ENGINE RUN-IN PROCEDURE - CHASSIS DYNAMOMETER

ENGINE RUN-IN PROCEDURE WITHOUT DYNAMOMETER

SECTION 9 - ENGINE REMOVE AND INSTALL

ENGINE REMOVE AND INSTALL GENERAL INFORMATION

ENGINE REMOVE AND INSTALL SERVICE TOOLS

ENGINE REMOVAL

ENGINE MOUNTS INSPECTION

ENGINE INSTALLATION

SECTION V - ENGINE COMPONENT SPECIFICATIONS

ENGINE COMPONENT SPECIFICATIONS GENERAL INFORMATION

COMPONENT SPECIFICATIONS AND TORQUE VALUES

DRIVE BELT TENSION

FRACTION, DECIMAL, MILLIMETER CONVERSIONS

WEIGHT AND MEASURES - CONVERSION FACTORS

NEWTON-METER TO FOOT POUND CONVERSION CHART

CAPSCREW MARKINGS AND TORQUE VALUES

PIPE PLUG TORQUE VALUES

TORQUE VALUES FOR STRAIGHT THREAD FITTINGS AND PLUGS

TAP-DRILL CHART - U.S. CUSTOMARY & METRIC

SECTION L - SERVICE LITERATURE

ADDITIONAL SERVICE LITERATURE

SERVICE LITERATURE ORDERING LOCATION

LITERATURE ORDER FORM

SECTION C - COMPONENT MANUFACTURERS

COMPONENT MANUFACTURERS' ADDRESSES

INDEX

This manuals will assist you in diagnosing, repairing, adjusting, troubleshooting, assembling, and disassembling for your diesel engine.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

N14

The manual comprises 2 documents, including the Workshop Manual, and Diagnostic and Repair Manual

1. Workshop Manual (3810487)

Format: PDF, 587 pages

Language: English

Table of Contents:

INTRODUCTION

MANUAL ORGANIZATION

GENERAL REPAIR INSTRUCTIONS

GENERAL SAFETY INSTRUCTIONS

SYMBOLS USED IN THIS MANUAL

SIMBOLOS USADOS EN ESTE MANUAL

SYMBOLES UTILISES DANS CE MANUEL

SYMBOLE

ILLUSTRATIONS

GLOSSARY OF TERMS

ENGINE IDENTIFICATION

ENGINE DIAGRAMS

GENERAL CLEANING INSTRUCTIONS

GROUP 0 - ENGINE DISASSEMBLY AND ASSEMBLY

COOLANT - DRAINAGE

ENGINE DISASSEMBLY AND ASSEMBLY - SERVICE TOOLS

ENGINE DISASSEMBLY AND ASSEMBLY - GENERAL INFORMATION

ENGINE - PREPARATION FOR CLEANING

COOLANT FILTER - REMOVAL

LUBRICATING OIL FILTER - REMOVAL

CRANKCASE BREATHER - REMOVAL

TURBOCHARGER - REMOVAL

EXHAUST MANIFOLD - REMOVAL

STARTING MOTOR - REMOVAL

FAN AND FAN SPACER - REMOVAL

ALTERNATOR BELTS - REMOVAL

ALTERNATOR - REMOVAL

ALTERNATOR MOUNTING BRACKET - REMOVAL

LUBRICATING OIL COOLER ASSEMBLY - REMOVAL

COOLANT INLET TRANSFER CONNECTION - REMOVAL

DIPSTICK TUBE AND HOUSING - REMOVAL

PISTON COOLING NOZZLES - REMOVAL

WATER HEADER COVERS - REMOVAL

ENGINE - INSTALLATION ON THE REBUILD STAND

FLYWHEEL - REMOVAL

FLYWHEEL HOUSING - REMOVAL

REAR COVER - REMOVAL

CRANKSHAFT SEAL, REAR - REMOVAL

FAN BELTS - REMOVAL

FAN HUB AND FAN HUB SUPPORT BRACKET - REMOVAL

WATER PUMP BELT - REMOVAL

CELECT™ COOLANT TEMPERATURE SENSOR - REMOVAL

THERMOSTAT HOUSING - REMOVAL

AIR COMPRESSOR COOLANT INLET AND OUTLET TUBES - REMOVAL

WATER PUMP - REMOVAL

ACCESSORY DRIVE PULLEY - REMOVAL

VIBRATION DAMPER - REMOVAL

ENGINE SUPPORT BRACKET, FRONT - REMOVAL

STC EXTERNAL OIL PLUMBING - REMOVAL

STC OIL CONTROL VALVE - REMOVAL

CELECT™ ACTUATOR HARNESS - REMOVAL

CELECT™ SENSOR HARNESS - REMOVAL

CELECT™ ELECTRONIC CONTROL MODULE (ECM) - REMOVAL

CELECT™ AMBIENT AIR PRESSURE SENSOR -REMOVAL

CELECT™ LUBRICATING OIL PRESSURE SENSOR - REMOVAL

CELECT™ ECM COOLING PLATE - REMOVAL

FUEL PUMP - REMOVAL

AIR COMPRESSOR - REMOVAL

ACCESSORY DRIVE - REMOVAL

FUEL TUBING - REMOVAL

CELECT™ ENGINE POSITION SENSOR (EPS) - REMOVAL

LUBRICATING OIL TRANFER TUBE - REMOVAL

LUBRICATING OIL PUMP SIGNAL LINE - REMOVAL

LUBRICATING OIL PUMP - REMOVAL

VISCOSITY SENSOR - REMOVAL

CELECT™ BOOST PRESSURE SENSOR - REMOVAL

CELECT™ INTAKE AIR TEMPERATURE SENSOR - REMOVAL

INTAKE MANIFOLD - REMOVAL

ROCKER HOUSING COVERS - REMOVAL

ENGINE BRAKES - REMOVAL

ROCKER LEVER SHAFT ASSEMBLIES - REMOVAL

VALVE CROSSHEADS - REMOVAL

PUSH TUBES - REMOVAL

INJECTORS - REMOVAL

ROCKER LEVER HOUSING - REMOVAL

FUEL CROSSOVERS - REMOVAL

CYLINDER HEADS - REMOVAL

CAM FOLLOWER ASSEMBLIES - REMOVAL

CAMSHAFT BEARING SUPPORT - REMOVAL

LUBRICATING OIL PAN - REMOVAL

GEAR COVER - REMOVAL

CRANKSHAFT SEAL, FRONT - REMOVAL

ACCESSORY DRIVE SEAL - REMOVAL

CAMSHAFT - REMOVAL

PISTON AND CONNECTING ROD ASSEMBLIES - REMOVAL

CYLINDER LINERS - REMOVAL

CRANKSHAFT - REMOVAL

CYLINDER BLOCK - REMOVAL FROM THE REBUILD STAND

CYLINDER BLOCK - INSTALLATION ON THE REBUILD STAND

CRANKSHAFT - INSTALLATION

CYLINDERS LINERS - INSTALLATION

PISTON AND CONNECTING ROD ASSEMBLIES - ASSEMBLY AND INSTALLATION

REAR COVER - INSTALLATION

CRANKSHAFT SEAL, REAR - INSTALLATION

FLYWHEEL HOUSING - INSTALLATION

FLYWHEEL - INSTALLATION

CYLINDER HEADS - INSTALLATION

CAMSHAFT INSTALLATION

CAM FOLLOWER ASSEMBLIES - INSTALLATION

INJECTION TIMING - GENERAL INFORMATION

ACCESSORY DRIVE - INSTALLATION

CELECT™ ENGINE POSITION SENSOR (EPS) - INSTALLATION

LUBRICATING OIL PUMP - INSTALLATION

GEAR COVER - INSTALLATION

CRANKSHAFT SEAL, FRONT - INSTALLATION

CAMSHAFT BEARING SUPPORT - INSTALLATION

ACCESSORY DRIVE SEAL - INSTALLATION

ACCESSORY DRIVE PULLEY - INSTALLATION

LUBRICATING OIL PAN - INSTALLATION

FUEL CROSSOVERS - INSTALLATION

ROCKER LEVER HOUSING - INSTALLATION

INJECTORS - INSTALLATION

PUSH TUBES - INSTALLATION

VALVE CROSSHEADS - INSTALLATION

ROCKER LEVER SHAFT ASSEMBLIES - INSTALLATION

INJECTOR AND VALVE ADJUSTMENT

ENGINE BRAKE - INSTALLATION

ENGINE BRAKE ADJUSTMENT

ROCKER HOUSING COVERS - INSTALLATION

INTAKE MANIFOLD - INSTALLATION

CELECT™ INTAKE AIR TEMPERATURE SENSOR - INSTALLATION

CELECT™ BOOST PRESSURE SENSOR - INSTALLATION

VISCOSITY SENSOR - INSTALLATION

LUBRICATING OIL PUMP SIGNAL - INSTALLATION

LUBRICATING OIL TRANSFER TUBE - INSTALLATION

FUEL TUBING - INSTALLATION

AIR COMPRESSOR - INSTALLATION

FUEL PUMP - INSTALLATION

CELECT™ ECM COOLING PLATE - INSTALLATION

CELECT™ LUBRICATING OIL PRESSURE SENSOR - INSTALLATION

CELECT™ AMBIENT AIR PRESSURE SENSOR - INSTALLATION

CELECT™ ELECTRONIC CONTROL MODULE (ecm) - INSTALLATION

CELECT™ SENSOR HARNESS - INSTALLATION

CELECT™ ACTUATOR HARNESS - INSTALLATION

STC OIL CONTROL VALVE - INSTALLATION

STC EXTERNAL OIL PLUMBING - INSTALLATIONing - Installa-tion

ENGINE SUPPORT BRACKET, FRONT - INSTALLATION

VIBRATION DAMPER - INSTALLATION

WATER PUMP - INSTALLATION

WATER PUMP BELT - INSTALLATION AND ADJUSTMENT

THERMOSTAT HOUSING - INSTALLATION

CELECT™ COOLANT TEMPERATURE SENSOR - INSTALLATION

AIR COMPRESSOR COOLANT INLET AND OUTLET TUBES - INSTALLATION

FAN HUB AND FAN HUB SUPPORT - INSTALLATION

FAN BELTS - INSTALLATION AND ADJUSTMENT

ENGINE - REMOVAL FROM THE REBUILD STAND

PISTON COOLING NOZZLES - INSTALLATION

DIPSTICK TUBE AND HOUSING - INSTALLATION

WATER HEADER COVERS - INSTALLATION

COOLANT INLET TRANSFER CONNECTION - INSTALLATION

LUBRICATING OIL COOLER ASSEMBLY - INSTALLATION

ALTERNATOR MOUNTING BRACKET - INSTALLATION

ALTERNATOR - INSTALLATION

ALTERNATOR BELTS - INSTALLATION AND ADJUSTMENT

FAN AND FAN SPACER - INSTALLATION

STARTING MOTOR - INSTALLATION

EXHAUST MANIFOLD - INSTALLATION

TURBOCHARGER - INSTALLATION

CRANKCASE BREATHER TUBE - INSTALLATION

LUBRICATING OIL FILTER - INSTALLATION

COOLANT FILTER - INSTALLATION

ENGINE - COVERING ALL OPENINGS

GROUP 1 - CYLINDER BLOCK

CYLINDER BLOCK - SERVICE TOOLS

CYLINDER BLOCK - EXPLODED VIEW

CYLINDER BLOCK - GENERAL INFORMATION

CYLINDER BLOCK - DISASSEMBLY

CYLINDER BLOCK - CEANING AND INPECTION

CYLINDER BLOCK - MACHINING

CYLINDER BLOCK COUNTERBORE - INSPECTION AND MACHINING

CYLINDER BLOCK - ASSEMBLY

CYLINDER LINERS - CLEANING AND INSPECTION

PISTONS - CLEANING AND INSPECTION

CONNECTING ROD ASSEMBLIES - CLEANING AND INSPECTION

CONNECTING RODS - BEND AND TWIST INSPECTION

CONNECTING ROD BEARINGS - CLEANING AND INSPECTION

CRANKSHAFT ADAPTER - CLEANING AND INSPECTION

CRANKSHAFT PULLEY - CLEANING AND INSPECTION

VIBRATION DAMPER - CLEANING AND INSPECTION

CRANKSHAFT - CLEANING AND INSPECTION

CRANKSHAFT GEAR - REPLACEMENT

CRANKSHAFT BEARINGS - CLEANING AND INSPECTION

CAMSHAFT - CLEANING AND INSPECTION

CAMSHAFT GEAR - REPLACEMENT

GEAR COVER - CLEANING AND INSPECTION

REAR COVER - CLEANING AND INSPECTION

MAGNETIC CRACK INSPECTION

GROUP 2 - CYLINDER HEAD

CYLINDER HEAD - SERVICE TOOLS

CYLINDER HEA D - EXPLODED VIEW

CYLINDER HEAD - GENERAL INFORMATION

CYLINDER HEAD - CLEANING AND INSPECTION FOR REUSE

CYLINDER HEAD - REBUILD

CYLINDER HEAD - REPLACING THE VALVE GUIDES

CYLINDER HEAD - RING DOWEL REPLACEMENT

CYLINDER HEAD - REPLACING THE VALVE SEAT INSERTS

CYLINDER HEAD - GRINDING THE VALVES

CYLINDER HEAD - REPLACING THE INJECTOR SLEEVES

CYLINDER HEAD - PRESSURE TESTING

CYLINDER HEAD - MAGNETIC PARTICLE CHECKING

CYLINDER HEAD - VACUUM TESTING VALVE SEATING FOR REUSE

CYLINDER HEAD - VALVES - MAGNETIC CRACK INSPECTION

VALVE CROSSHEAD - CLEANING AND CHECKING FOR REUSE

VALVE CROSSHEAD - MAGNETIC CRACK INSPECTION

GROUP 3 - ROCKER LEVER HOUSING ASSEMBLY

ROCKER LEVER HOUSING ASSEMBLY - SERVICE TOOLS

ROCKER LEVER HOUSING COVER - EXPLODED VIEW

ROCKER LEVER HOUSING ASSEMBLY - EXPLODED VIEW

WATER MANIFOLD PLUMBING - EXPLODED VIEW

ROCKER LEVER HOUSING ASSEMBLY - GENERAL INFORMATION

ROCKER LEVER - CLEANING AND INSPECTION FOR REUSE

ROCKER LEVER BUSHING - REPLACEMENT

ROCKER LEVER - MAGNETIC CRACK INSPECTION

ROCKER HOUSING COVERS - CLEANING AND INSPECTION FOR REUSE

ROCKER LEVER HOUSING ASSEMBLY - CLEANING AND INSPECTION FOR REUSE

STC OIL PLUMBING - CLEANING AND INSPECTION FOR REUSE

RING AND PIN DOWEL - REPLACEMENT

METRI-PACK PASS THROUGH CONNECTOR - REPLACEMENT

GROUP 4 - CAM FOLLOWER ASSEMBLY

CAM FOLLOWER ASSEMBLY - SERVICE TOOLS

CAM FOLLOWER ASSEMBLY - EXPLODED VIEW

CAM FOLLOWER ASSEMBLY - GENERAL INFORMATION

CAM FOLLOWER ASSEMBLY - CLEANING AND INSPECTION FOR REUSE

CAM FOLLOWER ASSEMBLY - REBUILD

CAM FOLLOWER LEVER - ROLLER REPLACEMENT

CAM FOLLOWER SOCKET - REPLACEMENT

PUSH ROD - CLEANING AND INSPECTION FOR REUSE

GROUP 5 - FUEL SYSTEM

FUEL PUMP - GENERAL INFORMATION

FUEL PUMP - CLEANING AND INSPECTION FOR REUSE

FUEL PUMP - REBUILD

FUEL PUMP - CALIBRATION

GROUP 6 - INJECTORS AND FUEL LINES

INJECTOR - PT (TYPE D) STEP TIMING CONTROL - EXPLODED VIEW

INJECTOR - CELECT - EXPLODED VIEW

INJECTORS - PT (TYPE D) STEP TIMING CONTROL (STC) GENERAL INFORMATION

INJECTORS - CELECT - GENERAL INFORMATION

STEP TIMING CONTROL (STC) OIL CONTROL VALVE - GENERAL INFORMATION

INJECTORS - CLEANING THE EXTERIOR AND INSPECTION FOR REUSE

INJECTORS - REBUILD

INJECTORS - CALIBRATION

STC OIL CONTROL VALVE - CLEANING

FUEL TUBES, FITTINGS, AND MOUNTING PARTS - CLEANING AND INSPECTION FOR REUSE

GROUP 7 - LUBRICATING OIL SYSTEM

LUBRICATING OIL SYSTEM - SERVICE TOOLS

LUBRICATING OIL SYSTEM - EXPLODED VIEW

LUBRICATING OIL PUMP ASSEMBLY - EXPLODED VIEW

LUBRICATING OIL COOLER - EXPLODED VIEW

LUBRICATING OIL SYSTEM - GENERAL INFORMATION

LUBRICATING OIL PAN - CLEANING AND INSPECTION FOR REUSE

LUBRICATING OIL TRANSFER TUBE - CLEANING AND INSPECTION FOR REUSE

LUBRICATING OIL DIPSTICK AND DIPSTICK TUBE - CLEANING AND INSPECTION FOR REUSE

LUBRICATING OIL DIPSTICK - CALIBRATION

LUBRICATING OIL PUMP - CLEANING AND INSPECTION FOR REUSE

LUBRICATING OIL PUMP - REBUILD

LUBRICATING OIL PUMP BODY AND COVER BUSHING - REPLACEMENT

LUBRICATING OIL PUMP DRIVEN GEAR BUSHING - REPLACEMENT

LUBRICATING OIL PUMP DRIVE GEAR OR SHAFT - REPLACEMENT

LUBRICATING OIL PUMP DRIVEN SHAFT - REPLACEMENT

LUBRICATING OIL COOLER ASSEMBLY REBUILD

GROUP 8 - COOLING SYSTEM

COOLING SYSTEM - SERVICE TOOLS

N14 WATER PUMP AND IDLER ASSEMBLY - EXPLODED VIEW

WATER PUMP AND IDLER ASSEMBLY - GENERAL INFORMATION

WATER PUMP ASSEMBLY

WATER PUMP ASSEMBLY - REBUILD

WATER PUMP IDLER ASSEMBLY - CLEANING AND INSPECTION

WATER PUMP IDLER ASSEMBLY - REBUILD

THERMOSTAT HOUSING - CLEANING AND INSPECTION

COOLANT FILTER HEAD INSERT

COOLANT FILTER SHUTOFF VALVE

FAN - CLEANING AND INSPECTION

WATER TRANSFER TUBES - CLEANING AND INSPECTION

GROUP 9 - DRIVE UNITS

DRIVE UNITS - SERVICE TOOLS

ACCESSORY DRIVE - EXPLODED VIEW

DRIVE UNITS - GENERAL INFORMATION

ACCESSORY DRIVE - CLEANING AND INSPECTION FOR REUSE

ACCESSORY DRIVE - REBUILD

ACCESSORY DRIVE GEAR - REPLACEMENT

ACCESSORY DRIVE PULLEY - CLEANING AND INSPECTION FOR REUSE

ACCESSORY DRIVE PULLEY WEAR SLEEVE - REPLACEMENT

GROUP 10 - INTAKE AIR SYSTEM

SERVICE TOOLS

INTAKE AIR SYSTEM - EXPLODED VIEW

INTAKE AIR SYSTEM - GENERAL INFORMATION

TURBOCHARGER - CLEANING AND INSPECTION

TURBOCHARGER SHAFT AXIAL CLEARANCE CHECKING

TURBOCHARGER BEARING RADIAL CLEARANCE - CHECKING

INTAKE AIR PIPING - ELBOWS

INTAKE MANIFOLD - CLEANING AND INSPECTION

GROUP 11 - EXHAUST SYSTEM

EXHAUST SYSTEM - EXPLODED VIEW

EXHAUST SYSTEM - GENERAL INFORMATION

EXHAUST MANIFOLD - CLEANING AND INSPECTION FOR REUSE

EXHAUST MANIFOLD TURBOCHARGER MOUNTING STUD - REPLACEMENT (11-02)

GROUP 12 - AIR EQUIPMENT

AIR EQUIPMENT - GENERAL INFORMATION

AIR COMPRESSOR - CLEANING AND INSPECTION FOR REUSE

GROUP 13 - ELECTRICAL EQUIPMENT

ELECTRICAL EQUIPMENT - GENERAL INFORMATION

ALTERNATOR BRACKET - CLEANING AND INSPECTION FOR REUSE

ALTERNATOR ADJUSTING LINK - CLEANING AND INSPECTION FOR REUSE

STARTING MOTOR - CLEANING AND INSPECTION FOR REUSE

GROUP 14 - ENGINE TESTING

GENERAL INFORMATION

DEFINITION OF TERMS ON ENGINE PERFORMANCE CURVE

GENERAL RUN-IN PROCEDURES

GENERAL ENGINE TEST/RUN-IN SPECIFICATIONS

ENGINE TESTING - SERVICE TOOLS

ENGINE DYNAMOMETER - INSTALL ENGINE

PRIMING THE LUBRICATING OIL AND FUEL SYSTEMS

ENGINE RUN-IN PROCEDURE - ENGINE DYNAMOMETER

CHASSIS DYNAMOMETER OPERATION

GENERAL TEST PROCEDURE - CHASSIS DYNAMOMETER

ENGINE RUN-IN PROCEDURE - CHASSIS DYNAMOMETER

ENGINE RUN-IN PROCEDURE WITHOUT DYNAMOMETER

ENGINE PAINTING

ENGINE STORAGE - SHORT TERM

ENGINE STORAGE - LONG TERM

GROUP 15 - INSTRUMENTS AND CONTROLS

INSTRUMENTS AND CONTROLS - GENERAL INFORMATION

GROUP 16 - MOUNTING ADAPTATIONS

MOUNTING ADAPTATIONS

FLYWHEEL

FLYWHEEL RING GEAR

FLYWHEEL HOUSING - CLEANING AND INSPECTION FOR REUSE

FRONT ENGINE SUPPORT BRACKET - CLEANING AND INSPECTION FOR REUSE

GROUP 18 - SPECIFICATIONS

GENERAL ENGINE SPECIFICATIONS

CAPSCREW MARKINGS AND TORQUE VALUES

PIPE PLUG TORQUE VALUES

DECIMAL AND METRIC EQUIVALENTS

SPECIFICATIONS - GENERAL INFORMATION

ENGINE ASSEMBLY

CYLINDER BLOCK

CYLINDER HEAD

ROCKER LEVER HOUSING ASEMBLY

CAM FOLLOWER ASSEMBLY

FUEL PUMP - REBUILD SPECIFICATIONS

INJECTORS - REBUILD SPECIFICATIONS

LUBRICATING OIL SYSTEM

LUBRICATING OIL PUMP - INSPECTION SPECIFICATIONS

WATER PUMP ASSEMBLY - REBUILD SPECIFICATIONS

FAN HUB - INSPECTION SPECIFICATIONS

THERMOSTAT HOUSING ASSEMBLY - REBUILD SPECIFICATIONS

THERMOSTAT (RESERVE FLOW COOLING) - OPERATING TEMPERATURE

COOLING SYSTEM - TORQUE VALUES

FUEL PUMP AND COMPRESSOR DRIVE

TURBOCHARGER - INSPECTION SPECIFICATIONS

AIR COMPRESSOR - INSPECTION SPECIFICATIONS

ENGINE TESTING - TEST SPECIFICATIONS

VEHICLE BRAKING - REBUILD SPECIFICATIONS

GROUP 20 - VEHICLE BRAKING

VEHICLE BRAKING - GENERAL INFORMATION

COMPONENTS MANUFACTURERS: NAMES AND ADDRESSES

SERVICE LITERATURE

ADDITIONAL SERVICE LITERATURE

SERVICE LITERATURE ORDERING LOCATION

SERVICE PUBLICATIONS ORDER FORM

INDEX

LITERATURE SURVEY FORM

2. Diagnostic and Repair Manual (3810456)

Format: PDF, 812 pages

Language: English

Table of Contents:

SECTION I - INTRODUCTION

ABOUT THE MANUAL

HOW TO USE THE MANUAL

SYMBOLS

SIMBOLOS

SYMBOLE

SYMBOLES

ILLUSTRATIONS

GENERAL SAFETY INSTRUCTIONS

GENERAL REPAIR INSTRUCTIONS

GENERAL CLEANING INSTRUCTIONS

DEFINITION OF TERMS

SECTION E - ENGINE IDENTIFICATION

CUMMINS MODEL NAME

ENGINE DATAPLATE

FUEL PUMP DATAPLATE

ENGINE SPECIFICATIONS

ENGINE DIAGRAMS

SECTION T - TROUBLESHOOTING

PROCEDURES AND TECHNIQUES

TROUBLESHOOTING SYMPTOMS CHART

SECTION 1 - COOLING SYSTEM

COOLING SYSTEM GENERAL INFORMATION

COOLANT FLOW DIAGRAM

COOLING SYSTEM SPECIFICATIONS

THERMAL CONTROL SETTINGS

HEAVY DUTY COOLANT

SUPPLEMENTAL COOLANT ADDITIVES (SCA'S)

COOLING SYSTEM SERVICE TOOLS

COOLING SYSTEM WATER

ANTIFREEZE

COOLING SYSTEM SEALING ADDITIVES

COOLING SYSTEM SOLUBLE OILS

COOLANT ADDITIVE REQUIREMENT

COOLANT FILTER

DRAINING THE COOLING SYSTEM

CLEANING THE COOLING SYSTEM

FILLING THE COOLING SYSTEM

COOLING SYSTEM - TESTING FOR AIR OR COMBUSTION GASES

COOLING SYSTEM PRESSURE TESTING

HOSES - INSPECTION

COOLANT TEMPERATURE GAUGE - CHECKING

VENTING THE COOLING SYSTEM

RADIATOR PRESSURE CAP

RADIATOR AND CHARGE AIR COOLED FINS

RADIATOR SHUTTER OPERATION

FAN INSPECTION

FAN SHROUD INSPECTION

FAN SPACER AND PULLEY INSPECTION

FAN BELTS

FAN AND FAN HUB

VISCOUS FAN CLUTCH

ON-OFF THERMATIC FAN CLUTCH

WATER PUMP BELTS

WATER PUMP IDLER PULLEY

WATER PUMP

COOLANT FILTER HEAD INSERT

COOLANT FILTER SHUTOFF VALVE

THERMOSTAT HOUSING

THERMOSTAT SEAL

THERMOSTAT

SECTION 2 - LUBRICATING SYSTEM

LUBRICATING SYSTEM GENERAL INFORMATON

LUBRICATING OIL SYSTEM FLOW DIAGRAM

LUBRICATING OIL SYSTEM FLOW DIAGRAM

LUBRICATING OIL SYSTEM FLOW DIAGRAM - VISCOSITY SENSOR AND STC VALVE

LUBRICATING OIL SYSTEM SPECIFICATIONS

LUBRICATING OIL SYSTEM SERVICE TOOLS

LUBRICATING OIL SYSTEM DIAGNOSTIC CHECKING

LUBRICATING OIL AND FILTER ANALYSIS

LUBRICATING OIL FILTER

LUBRICATING OIL LEAKS

CRANKCASE BREATHER

DRAINING THE LUBRICATING OIL SYSTEM

FILLING THE LUBRICATING OIL SYSTEM

PRIMING THE LUBRICATING OIL SYSTEM

DIPSTICK TUBE AND HOUSING

DIPSTICK CALIBRATION

LUBRICATING OIL TRANSFER TUBE

LUBRICATING OIL PAN

LUBRICATING OIL PUMP

HIGH LUBRICATING OIL PRESSURE RELIEF VALVE

MAIN LUBRICATING OIL PRESSURE REGULATOR

LUBRICATING OIL PUMP SIGNAL LINE

LUBRICATING OIL PUMP SIGNAL LINE ORIFICE (IN CHASSIS)

VISCOSITY SENSOR - STC ENGINES

LUBRICATING OIL COOLER ASSEMBLY

PISTON COOLING NOZZLES

LUBRICATING OIL PRESSURE GAUGE

LUBRICATING OIL TEMPERATURE GAUGE

SECTION 3 - COMBUSTION AIR SYSTEM

COMBUSTION AIR SYSTEM GENERAL INFORMATION

AIR INTAKE SYSTEM FLOW DIAGRAM

EXHAUST SYSTEM FLOW DIAGRAM

COMBUSTION AIR SYSTEM SPECIFICATIONS

COMBUSTION AIR SYSTEM SERVICE TOOLS

AIR LEAKS - TESTING

TURBOCHARGER SEAL LEAK - TESTING

TURBOCHARGER - VERIFYING CORRECT PART NUMBER

INTAKE AIR RESTRICTION

EXHAUST RESTRICTION

TURBOCHARGER BLADE DAMAGE

TURBOCHARGER AXIAL AND RADIAL CLEARANCE

TURBOCHARGER REPLACEMENT

EXHAUST MANIFOLD

INTAKE MANIFOLD

CHARGE AIR COOLER

SECTION 4 - COMPRESSED AIR SYSTEM

COMPRESSED AIR SYSTEM GENERAL INFORMATION

COMPRESSED AIR SYSTEM FLOW DIAGRAMS

COMPRESSED AIR SYSTEM SPECIFICATIONS

COMPRESSED AIR SYSTEM SERVICE TOOLS

CARBON BUILDUP, AIR COMPRESSOR

GASKET LEAKS, AIR COMPRESSOR

COMPRESSOR UNLOADER VALVE

AIR GOVERNOR (AIR COMPRESSOR WILL NOT PUMP)

AIR GOVERNOR

AIR COMPRESSOR, CYLINDER HEAD

AIR COMPRESSOR

SECTION 5 - FUEL SYSTEM

FUEL SYSTEM GENERAL INFORMATION

FUEL SYSTEM FLOW DIAGRAMS

FUEL SYSTEM SPECIFICATIONS

FUEL SYSTEM - SERVICE TOOLS

FUEL SYSTEM MISCELLANEOUS INFORMATION

FUEL SYSTEM MAINTENANCE

FUEL PUMP

FUEL PUMP FLOW CHECKING, ROTATION AND PRIMING

FUEL PUMP SHUTOFF VALVE

FUEL PUMP ON-ENGINE ADJUSTMENT

AIR ACTUATED ROAD SPEED GOVERNOR

VS THROTTLE SHAFT

VS GOVERNOR ADJUSTING SCREW SEALING JAM NUTS

VS GOVERNOR IDLE SPRING

FUEL GEAR PUMP CHECK VALVE

INJECTORS

STC OIL CONTROL VALVE

STC OIL DELIVERY SYSTEM DIAGNOSTIC TESTING

STC OIL DELIVERY SYSTEM BLOCKAGE - OIL RIFLE TO OIL MANIFOLD

STC OIL DELIVERY SYSTEM BLOCKAGE/LEAKAGE - OIL MANIFOLD TO INJECTORS

CYLINDER MISFIRING/SMOKING LOCATION

AIR IN FUEL TESTING

LUBRICATING OIL DILUTION BY FUEL TESTING

FUEL PUMP INLET RESTRICTION

FUEL PUMP DRAIN LINE RESTRICTION

AFC NO-AIR CHECK

POWER CHECK

FUEL CONSUMPTION CHECK

THROTTLE RESPONSE TEST

STALL SPEED TESTING

OPERATING IN NORMAL TIMING

STALL SPEED CHECK LIST

VE/VMS - ROAD TEST - THROTTLE RESPONSE TEST WORKSHEET

SECTION 6 - ELECTRICAL SYSTEM

ELECTRICAL SYSTEM GENERAL INFORMATION

STARTING SYSTEM SPECIFICATIONS

ELECTRICAL SYSTEM SERVICE TOOLS

BATTERIES

BATTERY CABLES AND CONNECTIONS

STARTER CONNECTIONS

ALTERNATOR BELT

ALTERNATOR REPLACEMENT

STARTING MOTOR REPLACEMENT

SECTION 7 - BASE ENGINE COMPONENTS

BASE ENGINE COMPONENTS GENERAL INFORMATION

BASE ENGINE COMPONENTS SERVICE TOOLS

ROCKER HOUSING COVERS

ENGINE LIFTING BRACKETS

ENGINE LIFTING BRACKET - SERVICE BRACKET

OVERHEAD ADJUSTMENT

ENGINE BRAKE ADJUSTMENT

ENGINE BRAKE REPLACE

PUSH RODS REPLACE

STC OIL PLUMBING

ROCKER LEVERS REPLACE

ROCKER LEVER HOUSINGS REPLACEMENT

CYLINDER BLOCK COUNTERBORE LEAK

CYLINDER BLOCK DECK SURFACE

CYLINDER BLOCK COUNTERBORE - LEAK TESTING

CYLINDER HEAD CAPSCREW HOLES

CYLINDER HEAD CAPSCREW HOLE

CYLINDER LINER PROTRUSION

CYLINDER HEAD GASKET(S) REPLACEMENT

CYLINDER HEADS REPLACE

CYLINDER HEAD PRESSURE TESTING

CAM FOLLOWERS REPLACE

INJECTION TIMING (GENERAL INFORMATION)

INJECTION TIMING

MAIN AND THRUST BEARINGS REPLACE

CONNECTING ROD BEARINGS REPLACEMENT

PISTONS AND RINGS REPLACEMENT

CONNECTING RODS REPLACEMENT

CYLINDER LINERS REPLACEMENT

ACCESSORY DRIVE PULLEY REPLACEMENT

WEAR SLEEVE, ACCESSORY DRIVE PULLEY REPLACEMENT

SEAL, ACCESSORY DRIVE REPLACEMENT

ACCESSORY DRIVE REPLACEMENT

VIBRATION DAMPER

CRANKSHAFT PULLEY REPLACEMENT

SEAL, FRONT CRANKSHAFT REPLACEMENT

CAMSHAFT BEARING SUPPORT REPLACEMENT

FRONT ENGINE SUPPORT BRACKET REPLACEMENT

GEAR COVER REPLACEMENT

CRANKSHAFT GEAR REPLACEMENT

CAMSHAFT REPLACEMENT

CAMSHAFT GEAR REPLACEMENT

CAMSHAFT BUSHING REPLACEMENT

FLYWHEEL REPLACEMENT

SEAL, REAR CRANKSHAFT REPLACEMENT

FLYWHEEL HOUSING REPLACEMENT

FLYWHEEL HOUSING REDOWEL TO CYLINDER BLOCK

STRAIGHT THREAD PLUGS, PIPE PLUGS AND CUP PLUGS REPLACEMENT

SECTION 8 - ENGINE TESTING

ENGINE TESTING GENERAL INFORMATION

DEFINITIONS OF TERMS ON ENGINE PERFORMANCE CURVE

GENERAL RUN-IN PROCEDURES

GENERAL ENGINE TEST/RUN-IN SPECIFICATIONS

ENGINE TESTING - SERVICE TOOLS

ENGINE DYNAMOMETER - INSTALL ENGINE

FUEL FLOW MEASUREMENT ON ENGINE OR CHASSIS DYNAMOMETER

INTAKE MANIFOLD BOOST PRESSURE CORRECTION FACTORS

ENGINE RUN-IN PROCEDURE - ENGINE DYNAMOMETER

DYNAMOMETER WORKSHEET

CHASSIS DYNAMOMETER OPERATION

GENERAL TEST PROCEDURE - CHASSIS DYNAMOMETER

ENGINE RUN-IN PROCEDURE - CHASSIS DYNAMOMETER

ENGINE RUN-IN PROCEDURE WITHOUT DYNAMOMETER

SECTION 9 - ENGINE REMOVE AND INSTALL

ENGINE REMOVE AND INSTALL GENERAL INFORMATION

ENGINE REMOVE AND INSTALL SERVICE TOOLS

ENGINE REMOVAL

ENGINE MOUNTS INSPECTION

ENGINE INSTALLATION

SECTION V - ENGINE COMPONENT SPECIFICATIONS

ENGINE COMPONENT SPECIFICATIONS GENERAL INFORMATION

COMPONENT SPECIFICATIONS AND TORQUE VALUES

DRIVE BELT TENSION

FRACTION, DECIMAL, MILLIMETER CONVERSIONS

WEIGHT AND MEASURES - CONVERSION FACTORS

NEWTON-METER TO FOOT POUND CONVERSION CHART

CAPSCREW MARKINGS AND TORQUE VALUES

PIPE PLUG TORQUE VALUES

TORQUE VALUES FOR STRAIGHT THREAD FITTINGS AND PLUGS

TAP-DRILL CHART - U.S. CUSTOMARY & METRIC

SECTION L - SERVICE LITERATURE

ADDITIONAL SERVICE LITERATURE

SERVICE LITERATURE ORDERING LOCATION

LITERATURE ORDER FORM

SECTION C - COMPONENT MANUFACTURERS

COMPONENT MANUFACTURERS' ADDRESSES

INDEX

General

Language

EnglishModel of Truck

N14Region

WorldWideType of Truck

Diesel EngineIncluded

Workshop Manual

1Diagnostic and Repair Manual

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.