$15.00

Language

EnglishModel of Truck

960E-1-KRegion

USAType of Document

Operate and Maintenance manualType of Truck

Electric Dump TruckIllustrated factory Operate and Maintenance manual for Komatsu Electric Dump Trucks Models 960E-1-K.

This manual will assist you in operating, and maintaining for your electric dump truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

960E-1-K (SN: A50003-)

Format: PDF, 174 pages

Language: English

Table of Contents:

STANDARD CHARTS AND TABLES

EFFECT OF SPECIAL LUBRICANTS On Fasteners and Standard Torque Values

STANDARD ASSEMBLY TORQUES For 12-Point, Grade 9 Cap screws (SAE)

STANDARD ASSEMBLY TORQUES For Class 10.9 Cap screws & Class 10 Nuts

SAFETY

GENERAL

PRECAUTIONS BEFORE OPERATION

OPERATING THE TRUCK

TOWING

WORKING NEAR BATTERIES

BEFORE PERFORMING MAINTENANCE

WHILE PERFORMING MAINTENANCE

TIRES

WHEN REPAIRS ARE NECESSARY

SPECIAL PRECAUTIONS FOR WORKING ON AC DRIVE TRUCKS

ADDITIONAL JOB SITE RULES

WARNINGS AND CAUTIONS

GRADE/SPEED CHART

INSTRUMENT PANEL

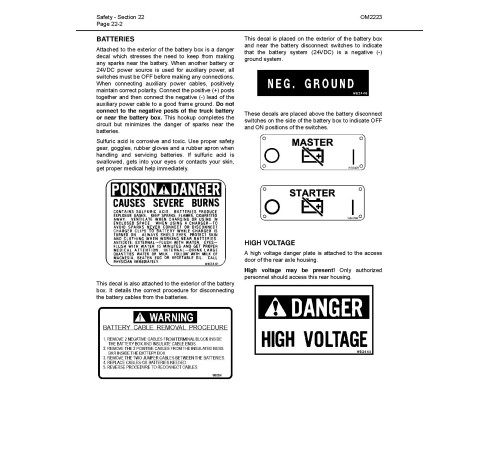

BATTERIES

HIGH VOLTAGE

RADIATOR

CRUSHING HAZARD

CYLINDER PRESSURE

FILLING THE HYDRAULIC TANK

HYDRAULIC OIL PRESSURE

EMERGENCY TOWING PROCEDURE

EMERGENCY DUMP PROCEDURE

GREASE POINT

WELDING

EMERGENCY SHUTDOWN

SPRING PRESSURE

ROPS/FOPS

EMERGENCEY EGRESS

PRODUCT IDENTIFICATION PLATE

LUBRICATION CHART

OPERATING INSTRUCTIONS

PREPARING FOR OPERATION

WALK AROUND INSPECTION

ENGINE START-UP

AFTER ENGINE START-UP

EMERGENCY STEERING SYSTEM

PRECAUTIONS DURING TRUCK OPERATION

OPERATING ON A HAUL ROAD

STARTING ON A GRADE WITH A LOADED TRUCK

LOADING THE DUMP BODY

DUMPING A LOAD

USING THE SPEED CONTROL FEATURE

SAFE PARKING PROCEDURE

NORMAL ENGINE SHUTDOWN PROCEDURE

SUDDEN LOSS OF ENGINE POWER

FUEL DEPLETION

TOWING

DISABLED TRUCK OPERATION

DISABLED TRUCK DUMPING PROCEDURE

RESERVE ENGINE OIL SYSTEM

OPERATOR CAB AND CONTROLS

STEERING WHEEL AND CONTROLS

PEDALS

GRADE/SPEED CHART

OVERHEAD PANEL COMPONENTS

CENTER CONSOLE

DIAGNOSTIC PORTS

OPERATOR’S SEAT

HEATER/AIR CONDITIONER COMPARTMENT AND CONTROLS

INSTRUMENT PANEL

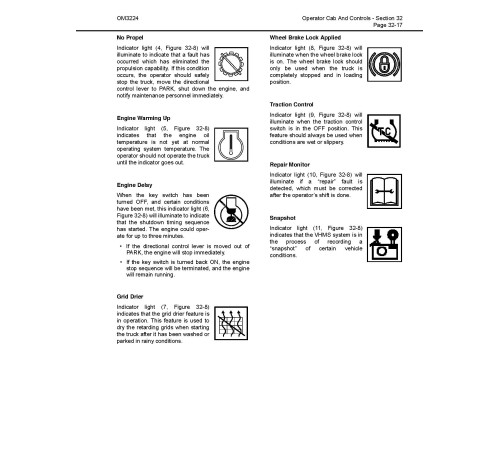

STATUS INDICATOR LIGHTS

DIGITAL DISPLAY OPERATION

VEHICLE HEALTH MONITORING SYSTEM (VHMS)

FUSES AND CIRCUIT BREAKERS

LUBRICATION AND SERVICE

960E-1K SERVICE CAPACITIES

HYDRAULIC TANK SERVICE

COOLING SYSTEM SERVICE

WHEEL MOTOR SERVICE

RESERVE OIL TANK SERVICE

AIR CLEANER SERVICE

LUBRICATION CHART

10 HOUR (DAILY) INSPECTION

10 HOUR (DAILY) INSPECTION (cont.)

INITIAL 50 HOUR LUBRICATION AND MAINTENANCE CHECKS

INITIAL 100 HOUR LUBRICATION AND MAINTENANCE CHECKS

INITIAL 250 HOUR LUBRICATION AND MAINTENANCE CHECKS

250 HOUR LUBRICATION AND MAINTENANCE CHECKS

500 HOUR LUBRICATION AND MAINTENANCE CHECKS

1000 HOUR LUBRICATION AND MAINTENANCE CHECKS

2000 HOUR LUBRICATION AND MAINTENANCE CHECKS

5000 HOUR LUBRICATION AND MAINTENANCE CHECKS

6000 HOUR LUBRICATION AND MAINTENANCE CHECKS

AUTOMATIC LUBRICATION SYSTEM

GENERAL DESCRIPTION

SYSTEM COMPONENTS

SYSTEM OPERATION

GENERAL INSTRUCTIONS

LUBRICANT PUMP

INJECTORS (SL-1 Series “H”)

PREVENTIVE MAINTENANCE PROCEDURES

SYSTEM CHECKOUT

SYSTEM TROUBLESHOOTING CHART

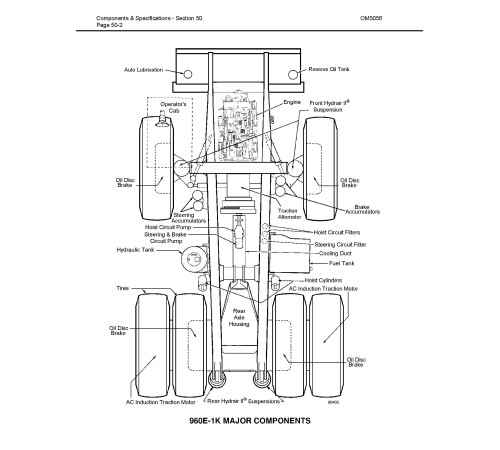

COMPONENTS & SPECIFICATIONS

MAJOR COMPONENT DESCRIPTIONS

SPECIFICATIONS

PAYLOAD METER III™

Introduction

COMPONENT DESCRIPTION

LOAD DISPLAY AND OPERATOR SWITCHES

PAYLOAD OPERATION & CALCULATION

SOURCES FOR PAYLOAD ERROR

HAUL CYCLE DATA

PDM SOFTWARE OVERVIEW

DOWNLOADING DATA

PLM III SYSTEM CONFIGURATION

DATA ANALYSIS

AM/FM RADIO / CD / MP3 / USB / iPOD™ / AUX PLAYER

OPERATING INSTRUCTIONS

This manual will assist you in operating, and maintaining for your electric dump truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

960E-1-K (SN: A50003-)

Format: PDF, 174 pages

Language: English

Table of Contents:

STANDARD CHARTS AND TABLES

EFFECT OF SPECIAL LUBRICANTS On Fasteners and Standard Torque Values

STANDARD ASSEMBLY TORQUES For 12-Point, Grade 9 Cap screws (SAE)

STANDARD ASSEMBLY TORQUES For Class 10.9 Cap screws & Class 10 Nuts

SAFETY

GENERAL

PRECAUTIONS BEFORE OPERATION

OPERATING THE TRUCK

TOWING

WORKING NEAR BATTERIES

BEFORE PERFORMING MAINTENANCE

WHILE PERFORMING MAINTENANCE

TIRES

WHEN REPAIRS ARE NECESSARY

SPECIAL PRECAUTIONS FOR WORKING ON AC DRIVE TRUCKS

ADDITIONAL JOB SITE RULES

WARNINGS AND CAUTIONS

GRADE/SPEED CHART

INSTRUMENT PANEL

BATTERIES

HIGH VOLTAGE

RADIATOR

CRUSHING HAZARD

CYLINDER PRESSURE

FILLING THE HYDRAULIC TANK

HYDRAULIC OIL PRESSURE

EMERGENCY TOWING PROCEDURE

EMERGENCY DUMP PROCEDURE

GREASE POINT

WELDING

EMERGENCY SHUTDOWN

SPRING PRESSURE

ROPS/FOPS

EMERGENCEY EGRESS

PRODUCT IDENTIFICATION PLATE

LUBRICATION CHART

OPERATING INSTRUCTIONS

PREPARING FOR OPERATION

WALK AROUND INSPECTION

ENGINE START-UP

AFTER ENGINE START-UP

EMERGENCY STEERING SYSTEM

PRECAUTIONS DURING TRUCK OPERATION

OPERATING ON A HAUL ROAD

STARTING ON A GRADE WITH A LOADED TRUCK

LOADING THE DUMP BODY

DUMPING A LOAD

USING THE SPEED CONTROL FEATURE

SAFE PARKING PROCEDURE

NORMAL ENGINE SHUTDOWN PROCEDURE

SUDDEN LOSS OF ENGINE POWER

FUEL DEPLETION

TOWING

DISABLED TRUCK OPERATION

DISABLED TRUCK DUMPING PROCEDURE

RESERVE ENGINE OIL SYSTEM

OPERATOR CAB AND CONTROLS

STEERING WHEEL AND CONTROLS

PEDALS

GRADE/SPEED CHART

OVERHEAD PANEL COMPONENTS

CENTER CONSOLE

DIAGNOSTIC PORTS

OPERATOR’S SEAT

HEATER/AIR CONDITIONER COMPARTMENT AND CONTROLS

INSTRUMENT PANEL

STATUS INDICATOR LIGHTS

DIGITAL DISPLAY OPERATION

VEHICLE HEALTH MONITORING SYSTEM (VHMS)

FUSES AND CIRCUIT BREAKERS

LUBRICATION AND SERVICE

960E-1K SERVICE CAPACITIES

HYDRAULIC TANK SERVICE

COOLING SYSTEM SERVICE

WHEEL MOTOR SERVICE

RESERVE OIL TANK SERVICE

AIR CLEANER SERVICE

LUBRICATION CHART

10 HOUR (DAILY) INSPECTION

10 HOUR (DAILY) INSPECTION (cont.)

INITIAL 50 HOUR LUBRICATION AND MAINTENANCE CHECKS

INITIAL 100 HOUR LUBRICATION AND MAINTENANCE CHECKS

INITIAL 250 HOUR LUBRICATION AND MAINTENANCE CHECKS

250 HOUR LUBRICATION AND MAINTENANCE CHECKS

500 HOUR LUBRICATION AND MAINTENANCE CHECKS

1000 HOUR LUBRICATION AND MAINTENANCE CHECKS

2000 HOUR LUBRICATION AND MAINTENANCE CHECKS

5000 HOUR LUBRICATION AND MAINTENANCE CHECKS

6000 HOUR LUBRICATION AND MAINTENANCE CHECKS

AUTOMATIC LUBRICATION SYSTEM

GENERAL DESCRIPTION

SYSTEM COMPONENTS

SYSTEM OPERATION

GENERAL INSTRUCTIONS

LUBRICANT PUMP

INJECTORS (SL-1 Series “H”)

PREVENTIVE MAINTENANCE PROCEDURES

SYSTEM CHECKOUT

SYSTEM TROUBLESHOOTING CHART

COMPONENTS & SPECIFICATIONS

MAJOR COMPONENT DESCRIPTIONS

SPECIFICATIONS

PAYLOAD METER III™

Introduction

COMPONENT DESCRIPTION

LOAD DISPLAY AND OPERATOR SWITCHES

PAYLOAD OPERATION & CALCULATION

SOURCES FOR PAYLOAD ERROR

HAUL CYCLE DATA

PDM SOFTWARE OVERVIEW

DOWNLOADING DATA

PLM III SYSTEM CONFIGURATION

DATA ANALYSIS

AM/FM RADIO / CD / MP3 / USB / iPOD™ / AUX PLAYER

OPERATING INSTRUCTIONS

General

Language

EnglishModel of Truck

960E-1-KRegion

USAType of Document

Operate and Maintenance manualType of Truck

Electric Dump TruckReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.