$15.00

Language

EnglishModel of Truck

HD1500-5Region

USAType of Document

Operate and Maintenance manualType of Truck

Rigid Dump TruckIllustrated factory Operate and Maintenance manual for Komatsu Rigid Dump Trucks Models HD1500-5.

This manual will assist you in operating, and maintaining for your rigid dump truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

HD1500-5 (SN: A30070-30071; A30077-30077)

Format: PDF, 178 pages

Language: English

Table of Contents:

Truck Model Illustration

ABOUT THIS MANUAL

STANDARD CHARTS AND TABLES

SAFETY

Safety Rules

Safety Features

Clothing And Personal Items

Unauthorized Modification

Leaving The Operators Seat

Mounting And Dismounting

Fire Prevention For Fuel And Oil

Precautions With High Temperature Fluids

Asbestos Dust Hazard Prevention

Prevention Of Injury By Work Equipment

Fire Extinguisher And First Aid Kit

Precautions For ROPS

Precautions For Attachments

HAUL ROADS

BEFORE STARTING THE ENGINE

Fire Prevention

Preparing For Operation

Ventilation In Enclosed Areas

In Operators Cab - Before Starting The Engine

Mirrors, Windows, And Lights

OPERATING THE MACHINE

When Starting The Engine

Precautions For Starting Machine

Truck Operation - General

Traveling

Traveling In Reverse

Traveling On Slopes

Ensure Good Visibility

Operate Carefully On Snow

Avoid Damage To Dump Body

TABLE OF CONTENTS

Driving Near High Voltage Cables

When Dumping

Working On Loose Ground

Loading The Body

Parking The Machine

TOWING

WORKING NEAR BATTERIES

Battery Hazard Prevention

Starting With Booster Cables

PRECAUTIONS FOR MAINTENANCE

BEFORE PERFORMING MAINTENANCE

Warning Tag

Proper Tools

Stopping The Engine Before Service

Securing The Dump Body

DURING MAINTENANCE

Personnel

Attachments

Working Under The Machine

Keep The Machine Clean

Rules To Follow When Adding Fuel Or Oil

Radiator Water Level

Use Of Lighting

Precautions With The Battery

Handling High Pressure Hoses

Precautions With High PressureOil

Precautions When Performing Maintenance Near High Temperature Or High Pressure

Rotating Fan And Belts

Waste Materials

TIRES

Handling Tires

Storing Tires After Removal

WHEN REPAIRS ARE NECESSARY

ADDITIONAL JOB SITE RULES

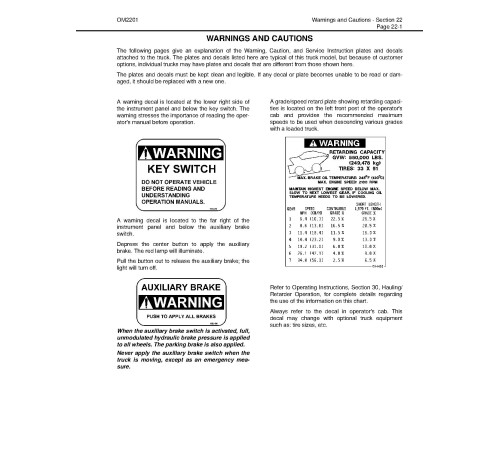

WARNINGS AND CAUTIONS

OPERATING INSTRUCTIONS

PREPARING FOR OPERATION

Safety Is Thinking Ahead

At The Truck - Ground Level Walk Around Inspection

ENGINE START-UP SAFETY PRACTICES

EMERGENCY STEERING SYSTEM

Operation

Pre-Operation Testing

AFTER THE ENGINE HAS STARTED

MACHINE OPERATION SAFETY PRECAUTIONS

LOADING

HAULING

RETARDER OPERATION

PASSING

DUMPING

Raising the Dump Body

Lowering The Dump Body

SAFE PARKING

SHUTDOWN PROCEDURE

SUDDEN LOSS OF ENGINE POWER

Emergency Steering And Braking

DISABLED TRUCK DUMPING

Hookup

Raising the Body

Lowering the Body

DISABLED TRUCK STEERING AND BRAKING

TOWING

OPERATOR CAB AND CONTROLS

STEERING WHEEL AND CONTROLS

Horn Button

Telescope Lock Ring

Tilt Wheel Lever

Turn Signal / Headlight Dimmer

Windshield Wiper / Washer Control

RETARDER CONTROL LEVER

SERVICE BRAKE PEDAL

ACCELERATOR (THROTTLE) PEDAL

INSTRUMENT PANEL

HEATER / AIR CONDITIONER COMPARTMENT AND CONTROLS

Defroster Vent Control Switch

Heat Vent Control Switch

Fan Control Knob

Temperature Control Knob

Air Conditioner Control Switch

Heater/Air Conditioner Vents

RETARDING CAPACITY CHART

Radio Speakers

MOM Display Screen

MOM Dimmer Switch

Warning Alarm Buzzer

Cab Radio

PMC Interface Connector

Air Cleaner Vacuum Gauges

Payload Meter

Windshield Wipers

CENTER CONSOLE

Transmission Range Selector

Control Switches

Shift Limiter Switch

F1 Start Switch

Hoist Control Lever

Parking Brake Switch

Brake Lock Switch

LH Window Control Switch

RH Window Control Switch

Ash Tray

Lighter

Passenger Seat w/Safety Belt

OPERATOR SEAT

Adjustment

INSTRUMENT PANEL AND INDICATORS

Keyswitch

Auxiliary Brake Switch

RH Control/Indicator Panel (Pod)

Center Display Panel

LH Control/Indicator Panel (Pod)

Ladder Light Switch

Head Light Switch

BackUp/Deck Light Switch

RH Control/Indicator Panel (Pod)

Cold Weather Starting Aid (Ether Injection) Switch

Hazard Warning Lights Switch

Automatic Idle Selector Switch (AISS)

Air Conditioner and Heater Vent

ASR Cut (Traction Control) Switch (Option)

Center Display Panel

Air Pressure Monitor (Not Used)

Air Pressure Gauge (Not Used)

Coolant Temperature Monitor

Engine Cooling Water Temperature Gauge

Torque Converter Oil Temperature Monitor

Torque Converter Oil Temperature Gauge

Retarder Oil Temperature Monitor

Retarder Oil Temperature Gauge

Left Turn Signal Pilot Lamp

High Beam Pilot Lamp

Right Turn Signal Pilot Lamp

Speedometer

Tachometer

Lock-up Pilot Lamp

Shift Limiter Pilot Lamp

Shift Indicator

Transmission Shift Position Pilot Lamp

Engine Controller Monitor

Automatic Transmission Mechatronics Monitor

Other Mechatronics Monitor (Optional)

Fuel Level Monitor

Fuel Gauge

Engine Power Derate Monitor

F1 Start Monitor

Auto Cruise Control (Not Used)

ASR Monitor (Optional)

ABS Monitor (Not Used)

Service Meter

Odometer

LH Control/Indicator Panel (Pod)

LH Panel/Pod Assembly

Engine Oil Temperature

Engine Coolant Level

Low Steering Pressure

Accumulator Pre-Charge

Battery Charge Amps

Check Engine

Parking Brake

Body Float

Transmission Oil Temperature

Service Brakes Applied

Maintenance Monitor

Transmission Oil Filters

Lamp Test

Low Brake Pressure

Lateral Slope Warning

Crankcase Pressure

Panel Dimmer Switch

Engine Oil Pressure

Central Warning Lamp

AC/Heater Vent

REAR OF OPERATOR CAB

QUANTUM FUEL SYSTEM DIAGNOSTICS

Determining Fault Codes

Exiting The Diagnostics Mode

MESSAGE FOR OPERATION AND MAINTENANCE ("MOM")

Truck Condition

Production Data During Operation - (Information from the Payload Meter)

Transmission Response With Fault Codes

Idle Validation Feature

CENTER ELECTRONIC DISPLAY PANEL

Action Code Display

Cancellation of Action Code

LUBRICATION AND SERVICE

COOLANT SPECIFICATIONS

Unacceptable Practices

QUICK FILL SERVICE CENTER

HOUR (DAILY) INSPECTION

HOUR INSPECTION

HOUR INSPECTION

HOUR INSPECTION

HOUR INSPECTION

HOUR INSPECTION

RADIATOR FILL PROCEDURE

TRANSMISSION OIL LEVEL CHECK

HYDRAULIC TANK SERVICE

Filling Instructions

Hydraulic Tank Service

STEERING CIRCUIT FILTER

Removal

Installation

HYDRAULIC TANK BREATHER

Cleaning

LINCOLN AUTOMATIC LUBRICATION SYSTEM

SYSTEM COMPONENTS

System Operation

System Priming

System Checkout

Pressure Reducer Adjustment

VDC Solid State Timer Check

VDC Solid State Timer Adjustment

Injectors (SL-1)

Injector Adjustment

Pump Cycle Timer (Flasher Timer):

Pump Cycle Timer (Flasher Timer) Installation

Pump Cycle Timer (Flasher Timer) Adjustment:

SYSTEM TROUBLESHOOTING CHART

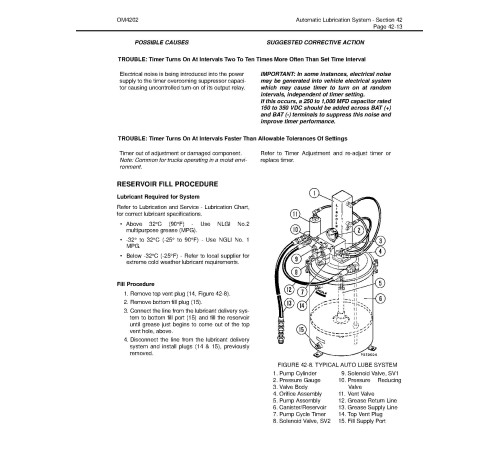

RESERVOIR FILL PROCEDURE

Lubricant Required for System

Fill Procedure

PREVENTIVE MAINTENANCE PROCEDURES

Daily Lubrication System Inspection

Hour Inspection

MAJOR COMPONENT DESCRIPTION

PAYLOAD METER III

RADIO, AM / FM STEREO CASSETTE

SETTING THE TIME

GENERAL RECEIVER FUNCTIONS

Turning The Power On And Off

Display

Setting The Default Display

Adjusting Display Brightness

OPERATING THE RADIO

BAND

TUNE/SEEK

Manual Tuning

SEEK Mode

SCAN

AUTO

ADJUSTING THE RECEIVER SETTINGS

PROGRAMMING PRESET STATIONS

OPERATION OF THE WEATHERBAND (U.S.)

SATELLITE RADIO

Operating Satellite Radio

Program Type Search (PTY)

CASSETTE PLAYER

Playing A Cassette

Cassette Functions

PROGRAMMABLE EJECT DEFAULT

Bad Tape Detect

CASSETTE PLAYER CLEANING

TRUCK MODEL ILLUSTRATION

TORQUE TABLES AND CONVERSION CHARTS

SAFETY

ADDITIONAL JOB SITE RULES

WARNINGS AND CAUTIONS

OPERATING INSTRUCTIONS

OPERATOR CAB AND CONTROLS

INSTRUMENT PANEL AND INDICATORS

MESSAGE FOR OPERATION AND MAINTENANCE ("MOM")

LUBRICATION AND SERVICE

LINCOLN AUTOMATIC LUBRICATION SYSTEM

SYSTEM TROUBLESHOOTING CHART

PREVENTIVE MAINTENANCE PROCEDURES

MAJOR COMPONENTS AND SPECIFICATIONS

SPECIFICATIONS

PAYLOAD METER II - ON BOARD WEIGHING SYSTEM

INDEX

GENERAL INFORMATION

Haul Cycles

LIGHTS, SWITCHES AND COMPONENTS

TIPS FOR OPERATION

EXTERNAL DISPLAY LIGHTS

THEORY OF OPERATION

Basic Description

Inclinometer

Linkage Factor

Gain Factor

Brake Lock

Sources of Error

Typical Data From Service Check Mode

Example Calculation of Payload

Viewing Payload Calculation Inputs

Checking the Gain

Adjusting the Gain

TYPES OF DATA STORED

Cycle Data

Engine ON/OFF Data

Fault Codes and Warning Data

Engine Operation

Total Payload and Total Number of Cycles

Other Data

OPERATOR FUNCTIONS

Using the Operator Load Counter

Viewing the Operator Load Counter

Clearing the Operator Load Counter

Dimming the Lights on the Display

INITIAL SETUP OF PAYLOAD METER

Switch Settings

Checking the Operator Check Mode

Checking the Service Check Mode

Checking the Gt setting:

Checking the Inclinometer Settings

Calibrating a Truck

DISPLAYS AT START-UP

Normal Operation

SETUP AND MAINTENANCE

Setting The Speed Limit

Setting the Option Code

Setting The Machine I.D. Code

Setting The Operator I.D. Code

Setting The Time and Date

DOWNLOAD OF INFORMATION

DISPLAY OF FAULT CODES

Monitoring Input Signals

Service Check Mode

UP FACTOR - PAYLOAD CALCULATION GAIN

PL MODE -LOAD CALCULATION TIMING

FINAL GEAR RATIO SELECTION

BATTERY REPLACEMENT PROCEDURE

Replacing the Battery

After Replacing the Battery

SUSPENSION PRESSURE SENSOR

Removal

Installation

INCLINOMETER

Removal

Installation

Adjustment

PAYLOAD METER BACK PANEL

CONNECTIONS

PAYLOAD CIRCUIT NUMBERS

PAYLOAD METER II RE-INITIALIZATION PROCEDURE

PAYLOAD CIRCUIT NUMBERS

PAYLOAD METER II RE-INITIALIZATION PROCEDURE

RADIO, AM / FM STEREO CASSETTE

This manual will assist you in operating, and maintaining for your rigid dump truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

HD1500-5 (SN: A30070-30071; A30077-30077)

Format: PDF, 178 pages

Language: English

Table of Contents:

Truck Model Illustration

ABOUT THIS MANUAL

STANDARD CHARTS AND TABLES

SAFETY

Safety Rules

Safety Features

Clothing And Personal Items

Unauthorized Modification

Leaving The Operators Seat

Mounting And Dismounting

Fire Prevention For Fuel And Oil

Precautions With High Temperature Fluids

Asbestos Dust Hazard Prevention

Prevention Of Injury By Work Equipment

Fire Extinguisher And First Aid Kit

Precautions For ROPS

Precautions For Attachments

HAUL ROADS

BEFORE STARTING THE ENGINE

Fire Prevention

Preparing For Operation

Ventilation In Enclosed Areas

In Operators Cab - Before Starting The Engine

Mirrors, Windows, And Lights

OPERATING THE MACHINE

When Starting The Engine

Precautions For Starting Machine

Truck Operation - General

Traveling

Traveling In Reverse

Traveling On Slopes

Ensure Good Visibility

Operate Carefully On Snow

Avoid Damage To Dump Body

TABLE OF CONTENTS

Driving Near High Voltage Cables

When Dumping

Working On Loose Ground

Loading The Body

Parking The Machine

TOWING

WORKING NEAR BATTERIES

Battery Hazard Prevention

Starting With Booster Cables

PRECAUTIONS FOR MAINTENANCE

BEFORE PERFORMING MAINTENANCE

Warning Tag

Proper Tools

Stopping The Engine Before Service

Securing The Dump Body

DURING MAINTENANCE

Personnel

Attachments

Working Under The Machine

Keep The Machine Clean

Rules To Follow When Adding Fuel Or Oil

Radiator Water Level

Use Of Lighting

Precautions With The Battery

Handling High Pressure Hoses

Precautions With High PressureOil

Precautions When Performing Maintenance Near High Temperature Or High Pressure

Rotating Fan And Belts

Waste Materials

TIRES

Handling Tires

Storing Tires After Removal

WHEN REPAIRS ARE NECESSARY

ADDITIONAL JOB SITE RULES

WARNINGS AND CAUTIONS

OPERATING INSTRUCTIONS

PREPARING FOR OPERATION

Safety Is Thinking Ahead

At The Truck - Ground Level Walk Around Inspection

ENGINE START-UP SAFETY PRACTICES

EMERGENCY STEERING SYSTEM

Operation

Pre-Operation Testing

AFTER THE ENGINE HAS STARTED

MACHINE OPERATION SAFETY PRECAUTIONS

LOADING

HAULING

RETARDER OPERATION

PASSING

DUMPING

Raising the Dump Body

Lowering The Dump Body

SAFE PARKING

SHUTDOWN PROCEDURE

SUDDEN LOSS OF ENGINE POWER

Emergency Steering And Braking

DISABLED TRUCK DUMPING

Hookup

Raising the Body

Lowering the Body

DISABLED TRUCK STEERING AND BRAKING

TOWING

OPERATOR CAB AND CONTROLS

STEERING WHEEL AND CONTROLS

Horn Button

Telescope Lock Ring

Tilt Wheel Lever

Turn Signal / Headlight Dimmer

Windshield Wiper / Washer Control

RETARDER CONTROL LEVER

SERVICE BRAKE PEDAL

ACCELERATOR (THROTTLE) PEDAL

INSTRUMENT PANEL

HEATER / AIR CONDITIONER COMPARTMENT AND CONTROLS

Defroster Vent Control Switch

Heat Vent Control Switch

Fan Control Knob

Temperature Control Knob

Air Conditioner Control Switch

Heater/Air Conditioner Vents

RETARDING CAPACITY CHART

Radio Speakers

MOM Display Screen

MOM Dimmer Switch

Warning Alarm Buzzer

Cab Radio

PMC Interface Connector

Air Cleaner Vacuum Gauges

Payload Meter

Windshield Wipers

CENTER CONSOLE

Transmission Range Selector

Control Switches

Shift Limiter Switch

F1 Start Switch

Hoist Control Lever

Parking Brake Switch

Brake Lock Switch

LH Window Control Switch

RH Window Control Switch

Ash Tray

Lighter

Passenger Seat w/Safety Belt

OPERATOR SEAT

Adjustment

INSTRUMENT PANEL AND INDICATORS

Keyswitch

Auxiliary Brake Switch

RH Control/Indicator Panel (Pod)

Center Display Panel

LH Control/Indicator Panel (Pod)

Ladder Light Switch

Head Light Switch

BackUp/Deck Light Switch

RH Control/Indicator Panel (Pod)

Cold Weather Starting Aid (Ether Injection) Switch

Hazard Warning Lights Switch

Automatic Idle Selector Switch (AISS)

Air Conditioner and Heater Vent

ASR Cut (Traction Control) Switch (Option)

Center Display Panel

Air Pressure Monitor (Not Used)

Air Pressure Gauge (Not Used)

Coolant Temperature Monitor

Engine Cooling Water Temperature Gauge

Torque Converter Oil Temperature Monitor

Torque Converter Oil Temperature Gauge

Retarder Oil Temperature Monitor

Retarder Oil Temperature Gauge

Left Turn Signal Pilot Lamp

High Beam Pilot Lamp

Right Turn Signal Pilot Lamp

Speedometer

Tachometer

Lock-up Pilot Lamp

Shift Limiter Pilot Lamp

Shift Indicator

Transmission Shift Position Pilot Lamp

Engine Controller Monitor

Automatic Transmission Mechatronics Monitor

Other Mechatronics Monitor (Optional)

Fuel Level Monitor

Fuel Gauge

Engine Power Derate Monitor

F1 Start Monitor

Auto Cruise Control (Not Used)

ASR Monitor (Optional)

ABS Monitor (Not Used)

Service Meter

Odometer

LH Control/Indicator Panel (Pod)

LH Panel/Pod Assembly

Engine Oil Temperature

Engine Coolant Level

Low Steering Pressure

Accumulator Pre-Charge

Battery Charge Amps

Check Engine

Parking Brake

Body Float

Transmission Oil Temperature

Service Brakes Applied

Maintenance Monitor

Transmission Oil Filters

Lamp Test

Low Brake Pressure

Lateral Slope Warning

Crankcase Pressure

Panel Dimmer Switch

Engine Oil Pressure

Central Warning Lamp

AC/Heater Vent

REAR OF OPERATOR CAB

QUANTUM FUEL SYSTEM DIAGNOSTICS

Determining Fault Codes

Exiting The Diagnostics Mode

MESSAGE FOR OPERATION AND MAINTENANCE ("MOM")

Truck Condition

Production Data During Operation - (Information from the Payload Meter)

Transmission Response With Fault Codes

Idle Validation Feature

CENTER ELECTRONIC DISPLAY PANEL

Action Code Display

Cancellation of Action Code

LUBRICATION AND SERVICE

COOLANT SPECIFICATIONS

Unacceptable Practices

QUICK FILL SERVICE CENTER

HOUR (DAILY) INSPECTION

HOUR INSPECTION

HOUR INSPECTION

HOUR INSPECTION

HOUR INSPECTION

HOUR INSPECTION

RADIATOR FILL PROCEDURE

TRANSMISSION OIL LEVEL CHECK

HYDRAULIC TANK SERVICE

Filling Instructions

Hydraulic Tank Service

STEERING CIRCUIT FILTER

Removal

Installation

HYDRAULIC TANK BREATHER

Cleaning

LINCOLN AUTOMATIC LUBRICATION SYSTEM

SYSTEM COMPONENTS

System Operation

System Priming

System Checkout

Pressure Reducer Adjustment

VDC Solid State Timer Check

VDC Solid State Timer Adjustment

Injectors (SL-1)

Injector Adjustment

Pump Cycle Timer (Flasher Timer):

Pump Cycle Timer (Flasher Timer) Installation

Pump Cycle Timer (Flasher Timer) Adjustment:

SYSTEM TROUBLESHOOTING CHART

RESERVOIR FILL PROCEDURE

Lubricant Required for System

Fill Procedure

PREVENTIVE MAINTENANCE PROCEDURES

Daily Lubrication System Inspection

Hour Inspection

MAJOR COMPONENT DESCRIPTION

PAYLOAD METER III

RADIO, AM / FM STEREO CASSETTE

SETTING THE TIME

GENERAL RECEIVER FUNCTIONS

Turning The Power On And Off

Display

Setting The Default Display

Adjusting Display Brightness

OPERATING THE RADIO

BAND

TUNE/SEEK

Manual Tuning

SEEK Mode

SCAN

AUTO

ADJUSTING THE RECEIVER SETTINGS

PROGRAMMING PRESET STATIONS

OPERATION OF THE WEATHERBAND (U.S.)

SATELLITE RADIO

Operating Satellite Radio

Program Type Search (PTY)

CASSETTE PLAYER

Playing A Cassette

Cassette Functions

PROGRAMMABLE EJECT DEFAULT

Bad Tape Detect

CASSETTE PLAYER CLEANING

TRUCK MODEL ILLUSTRATION

TORQUE TABLES AND CONVERSION CHARTS

SAFETY

ADDITIONAL JOB SITE RULES

WARNINGS AND CAUTIONS

OPERATING INSTRUCTIONS

OPERATOR CAB AND CONTROLS

INSTRUMENT PANEL AND INDICATORS

MESSAGE FOR OPERATION AND MAINTENANCE ("MOM")

LUBRICATION AND SERVICE

LINCOLN AUTOMATIC LUBRICATION SYSTEM

SYSTEM TROUBLESHOOTING CHART

PREVENTIVE MAINTENANCE PROCEDURES

MAJOR COMPONENTS AND SPECIFICATIONS

SPECIFICATIONS

PAYLOAD METER II - ON BOARD WEIGHING SYSTEM

INDEX

GENERAL INFORMATION

Haul Cycles

LIGHTS, SWITCHES AND COMPONENTS

TIPS FOR OPERATION

EXTERNAL DISPLAY LIGHTS

THEORY OF OPERATION

Basic Description

Inclinometer

Linkage Factor

Gain Factor

Brake Lock

Sources of Error

Typical Data From Service Check Mode

Example Calculation of Payload

Viewing Payload Calculation Inputs

Checking the Gain

Adjusting the Gain

TYPES OF DATA STORED

Cycle Data

Engine ON/OFF Data

Fault Codes and Warning Data

Engine Operation

Total Payload and Total Number of Cycles

Other Data

OPERATOR FUNCTIONS

Using the Operator Load Counter

Viewing the Operator Load Counter

Clearing the Operator Load Counter

Dimming the Lights on the Display

INITIAL SETUP OF PAYLOAD METER

Switch Settings

Checking the Operator Check Mode

Checking the Service Check Mode

Checking the Gt setting:

Checking the Inclinometer Settings

Calibrating a Truck

DISPLAYS AT START-UP

Normal Operation

SETUP AND MAINTENANCE

Setting The Speed Limit

Setting the Option Code

Setting The Machine I.D. Code

Setting The Operator I.D. Code

Setting The Time and Date

DOWNLOAD OF INFORMATION

DISPLAY OF FAULT CODES

Monitoring Input Signals

Service Check Mode

UP FACTOR - PAYLOAD CALCULATION GAIN

PL MODE -LOAD CALCULATION TIMING

FINAL GEAR RATIO SELECTION

BATTERY REPLACEMENT PROCEDURE

Replacing the Battery

After Replacing the Battery

SUSPENSION PRESSURE SENSOR

Removal

Installation

INCLINOMETER

Removal

Installation

Adjustment

PAYLOAD METER BACK PANEL

CONNECTIONS

PAYLOAD CIRCUIT NUMBERS

PAYLOAD METER II RE-INITIALIZATION PROCEDURE

PAYLOAD CIRCUIT NUMBERS

PAYLOAD METER II RE-INITIALIZATION PROCEDURE

RADIO, AM / FM STEREO CASSETTE

General

Language

EnglishModel of Truck

HD1500-5Region

USAType of Document

Operate and Maintenance manualType of Truck

Rigid Dump TruckReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.