Model

DG728DDSKU

41347Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SA12V140Z-1: CEBM002603

$25.00

Language

EnglishModel of Truck

330MRegion

USAType of Document

Workshop ManualType of Truck

Rigid Dump TruckIllustrated factory Workshop Manual for Komatsu Rigid Dump Trucks Models 330M.

This manual will assist you in diagnosing, repairing, and adjusting for your rigid dump truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

330M (SN: A10190-10211)

Format: PDF, 895 pages

Language: English

Table of Contents:

A - GENERAL INFORMATION

MAJOR COMPONENTS and SPECIFICATIONS

GENERAL SAFETY

WARNINGS and CAUTIONS

STANDARD CHARTS and TABLES

STANDARD VALUE TABLES

B - STRUCTURES

GRILLE AND HOOD

DECKS

LEFT DECK and CAB

RIGHT DECK STRUCTURE

CENTER DECK STRUCTURE

DUMP BODY - REMOVAL

DUMP BODY - INSTALLATION

BODY PADS

BODY GUIDE

BODY PIN

ROCK EJECTORS

FUEL TANK

VENT

QUICK FUEL OPTION

C - ENGINE, RADIATOR and AIR CLEANER

RADIATOR

BRAKE OIL COOLER

FAN

FAN BELT

ENGINE

DRIVE LINE ADAPTER

AIR FILTRATION SYSTEM

MAIN FILTER ELEMENT

D - ELECTRICAL SYSTEM

24VDC ELECTRICAL SUPPLY SYSTEM

24VDC ELECTRICAL SYSTEM COMPONENTS

POINTS TO REMEMBER WHEN TROUBLESHOOTING

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

CHECKS BEFORE TROUBLESHOOTING

TYPE OF CONNECTOR and POSITION OF INSTALLATION

FOR ARSC (AUTOMATIC RETARDER SPEED CONTROL)

CONNECTOR PIN ALLOCATION CHART

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

EXPLANATIONS OF FUNCTIONS (CONTROL MECHANISM) OF ELECTRICAL SYSTEM

MONITOR PANEL ACTION CODES and SERVICE MODE

SELF-DIAGNOSTIC DISPLAY METHOD FOR MONITOR PANEL and CONTROLLERS

TABLE OF SERVICE CODES and ACTION CODES

METHOD OF USING TABLE

METHOD OF USING TROUBLESHOOTING CHARTS

ADJUSTING ELECTRONIC MONITOR (SPEEDOMETER, MODULE)

SETTING ROTARY SWITCH (MODEL and NETWORK DATA) WHEN REPLACING TRANSMISSION CONTROLLER

METHOD OF DELETING DATA FROM TRANSMISSION CONTROLLER MEMORY

TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM

MONITOR PANEL TROUBLESHOOTING

ENGINE ELECTRONIC DIAGNOSTIC SYSTEM

ELECTRICAL SPECIFICATIONS

HYDRAULIC and MECHANICAL SYSTEMS TROUBLESHOOTING

SUSPENSION CONTROLLER SYSTEM TROUBLESHOOTING (OPTIONAL) SP DIAGNOSTIC FLOWCHART

F - TRANSMISSION

TORQUE CONVERTER OPERATION

TRANSMISSION OPERATION

TRANSMISSION

TRANSMISSION FILTER

TRANSMISSION OIL COOLER

TRANSMISSION OIL STRAINER

TORQUE CONVERTER CONTROL VALVE

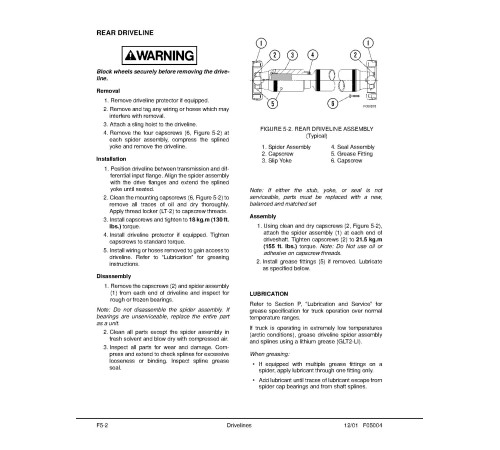

DRIVELINES and U-JOINTS

AUTOMATIC SHIFT CONTROL SYSTEM

G - WHEELS, SPINDLES and FINAL DRIVE

TIRES and RIMS

FRONT TIRE and RIM

REAR TIRE and RIM

TIRE MATCHING

FRONT WHEEL HUB and SPINDLES

FRONT WHEEL HUB

FRONT WHEEL BEARING and BRAKE DISC REPLACEMENT

FRONT WHEEL HUB INSTALLATION and BEARING ADJUSTMENT

A-FRAME

CENTER TIE ROD PIVOT

FINAL DRIVE ATTACHMENTS

FINAL DRIVE CENTER CASE ASSEMBLY

DIFFERENTIAL ASSEMBLY

FINAL DRIVE PLANETARIES and WHEEL HUBS

H - SUSPENSIONS

FRONT SUSPENSION

REAR SUSPENSION

OILING and CHARGING PROCEDURES

J - BRAKE SYSTEM

BRAKE CIRCUIT OPERATION

BRAKE CIRCUIT COMPONENT SERVICE

BRAKE CIRCUIT CHECKOUT AND ADJUSTMENT

FRONT BRAKES

REAR BRAKES

PARKING BRAKE

PARKING BRAKE RELEASE AFTER EMERGENCY APPLY

K - AIR SYSTEM

AIR SYSTEM OPERATION

COMPONENT DESCRIPTION

AIR SYSTEM COMPONENT REPAIR

RETARDER VALVE

L - HYDRAULIC SYSTEM

HYDRAULIC SYSTEM OPERATION

HYDRAULIC SYSTEM COMPONENT REPAIR

STEERING CIRCUIT

STEERING VALVE ASSEMBLY

STEERING CIRCUIT COMPONENT REPAIR

HOIST CIRCUIT OPERATION and COMPONENT DESCRIPTION

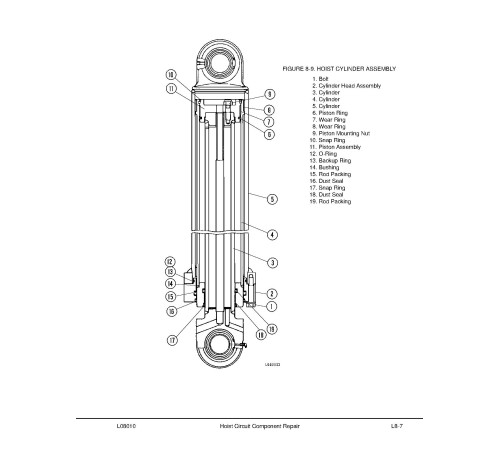

HOIST CIRCUIT COMPONENT REPAIR

HYDRAULIC SYSTEM CHECKOUT

M - OPTIONS and SPECIAL TOOLS

QUICK FUEL SYSTEM

SPECIAL TOOLS

AIR CONDITIONING SYSTEM

PAYLOAD METER II

EXHAUST BRAKE

N - OPERATOR'S CAB

TRUCK CAB

CAB COMPONENTS

OPERATOR COMFORT

OPERATOR CAB and CONTROLS

P - LUBRICATION and SERVICE

LUBRICATION and SERVICE

LUBRICATION SPECIFICATIONS CHARTS

10 HOUR (DAILY) LUBRICATION and MAINTENANCE CHECKS

FLUID LEVELS and OTHER CHECKS

ENGINE

WHEELS AND TIRES

OPERATIONAL CHECKS

250 HOUR LUBRICATION and MAINTENANCE CHECKS

INITIAL 250 HOUR SERVICE

EVERY 250 HOUR SERVICE

500 HOUR LUBRICATION and MAINTENANCE CHECKS

1000 HOUR LUBRICATION and MAINTENANCE CHECKS

2000 HOUR LUBRICATION and MAINTENANCE CHECKS

EVERY 5000 HOUR SERVICE

HYDRAULIC TANK SERVICE and FILLING INSTRUCTIONS

HYDRAULIC FILTERS

HYDRAULIC TANK BREATHER

HIGH PRESSURE HYDRAULIC FILTER SERVICE

TRANSMISSION FILTER SERVICE

PERIODIC REPLACEMENT OF COMPONENT PARTS FOR SAFETY DEVICES

Q - ALPHABETICAL INDEX

R - SYSTEM SCHEMATICS

HA204 AIR CIRCUIT PIPING

HA203 AIR SYSTEM SCHEMATIC

HH339 HYDRAULIC SYSTEM SCHEMATIC

HH340 HYDRAULIC SYSTEM PIPING

KT-T01 TRANSMISSION CROSS SECTION VIEW

HE462 ELECTRICAL WIRING SCHEMATIC

This manual will assist you in diagnosing, repairing, and adjusting for your rigid dump truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

330M (SN: A10190-10211)

Format: PDF, 895 pages

Language: English

Table of Contents:

A - GENERAL INFORMATION

MAJOR COMPONENTS and SPECIFICATIONS

GENERAL SAFETY

WARNINGS and CAUTIONS

STANDARD CHARTS and TABLES

STANDARD VALUE TABLES

B - STRUCTURES

GRILLE AND HOOD

DECKS

LEFT DECK and CAB

RIGHT DECK STRUCTURE

CENTER DECK STRUCTURE

DUMP BODY - REMOVAL

DUMP BODY - INSTALLATION

BODY PADS

BODY GUIDE

BODY PIN

ROCK EJECTORS

FUEL TANK

VENT

QUICK FUEL OPTION

C - ENGINE, RADIATOR and AIR CLEANER

RADIATOR

BRAKE OIL COOLER

FAN

FAN BELT

ENGINE

DRIVE LINE ADAPTER

AIR FILTRATION SYSTEM

MAIN FILTER ELEMENT

D - ELECTRICAL SYSTEM

24VDC ELECTRICAL SUPPLY SYSTEM

24VDC ELECTRICAL SYSTEM COMPONENTS

POINTS TO REMEMBER WHEN TROUBLESHOOTING

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

CHECKS BEFORE TROUBLESHOOTING

TYPE OF CONNECTOR and POSITION OF INSTALLATION

FOR ARSC (AUTOMATIC RETARDER SPEED CONTROL)

CONNECTOR PIN ALLOCATION CHART

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

EXPLANATIONS OF FUNCTIONS (CONTROL MECHANISM) OF ELECTRICAL SYSTEM

MONITOR PANEL ACTION CODES and SERVICE MODE

SELF-DIAGNOSTIC DISPLAY METHOD FOR MONITOR PANEL and CONTROLLERS

TABLE OF SERVICE CODES and ACTION CODES

METHOD OF USING TABLE

METHOD OF USING TROUBLESHOOTING CHARTS

ADJUSTING ELECTRONIC MONITOR (SPEEDOMETER, MODULE)

SETTING ROTARY SWITCH (MODEL and NETWORK DATA) WHEN REPLACING TRANSMISSION CONTROLLER

METHOD OF DELETING DATA FROM TRANSMISSION CONTROLLER MEMORY

TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM

MONITOR PANEL TROUBLESHOOTING

ENGINE ELECTRONIC DIAGNOSTIC SYSTEM

ELECTRICAL SPECIFICATIONS

HYDRAULIC and MECHANICAL SYSTEMS TROUBLESHOOTING

SUSPENSION CONTROLLER SYSTEM TROUBLESHOOTING (OPTIONAL) SP DIAGNOSTIC FLOWCHART

F - TRANSMISSION

TORQUE CONVERTER OPERATION

TRANSMISSION OPERATION

TRANSMISSION

TRANSMISSION FILTER

TRANSMISSION OIL COOLER

TRANSMISSION OIL STRAINER

TORQUE CONVERTER CONTROL VALVE

DRIVELINES and U-JOINTS

AUTOMATIC SHIFT CONTROL SYSTEM

G - WHEELS, SPINDLES and FINAL DRIVE

TIRES and RIMS

FRONT TIRE and RIM

REAR TIRE and RIM

TIRE MATCHING

FRONT WHEEL HUB and SPINDLES

FRONT WHEEL HUB

FRONT WHEEL BEARING and BRAKE DISC REPLACEMENT

FRONT WHEEL HUB INSTALLATION and BEARING ADJUSTMENT

A-FRAME

CENTER TIE ROD PIVOT

FINAL DRIVE ATTACHMENTS

FINAL DRIVE CENTER CASE ASSEMBLY

DIFFERENTIAL ASSEMBLY

FINAL DRIVE PLANETARIES and WHEEL HUBS

H - SUSPENSIONS

FRONT SUSPENSION

REAR SUSPENSION

OILING and CHARGING PROCEDURES

J - BRAKE SYSTEM

BRAKE CIRCUIT OPERATION

BRAKE CIRCUIT COMPONENT SERVICE

BRAKE CIRCUIT CHECKOUT AND ADJUSTMENT

FRONT BRAKES

REAR BRAKES

PARKING BRAKE

PARKING BRAKE RELEASE AFTER EMERGENCY APPLY

K - AIR SYSTEM

AIR SYSTEM OPERATION

COMPONENT DESCRIPTION

AIR SYSTEM COMPONENT REPAIR

RETARDER VALVE

L - HYDRAULIC SYSTEM

HYDRAULIC SYSTEM OPERATION

HYDRAULIC SYSTEM COMPONENT REPAIR

STEERING CIRCUIT

STEERING VALVE ASSEMBLY

STEERING CIRCUIT COMPONENT REPAIR

HOIST CIRCUIT OPERATION and COMPONENT DESCRIPTION

HOIST CIRCUIT COMPONENT REPAIR

HYDRAULIC SYSTEM CHECKOUT

M - OPTIONS and SPECIAL TOOLS

QUICK FUEL SYSTEM

SPECIAL TOOLS

AIR CONDITIONING SYSTEM

PAYLOAD METER II

EXHAUST BRAKE

N - OPERATOR'S CAB

TRUCK CAB

CAB COMPONENTS

OPERATOR COMFORT

OPERATOR CAB and CONTROLS

P - LUBRICATION and SERVICE

LUBRICATION and SERVICE

LUBRICATION SPECIFICATIONS CHARTS

10 HOUR (DAILY) LUBRICATION and MAINTENANCE CHECKS

FLUID LEVELS and OTHER CHECKS

ENGINE

WHEELS AND TIRES

OPERATIONAL CHECKS

250 HOUR LUBRICATION and MAINTENANCE CHECKS

INITIAL 250 HOUR SERVICE

EVERY 250 HOUR SERVICE

500 HOUR LUBRICATION and MAINTENANCE CHECKS

1000 HOUR LUBRICATION and MAINTENANCE CHECKS

2000 HOUR LUBRICATION and MAINTENANCE CHECKS

EVERY 5000 HOUR SERVICE

HYDRAULIC TANK SERVICE and FILLING INSTRUCTIONS

HYDRAULIC FILTERS

HYDRAULIC TANK BREATHER

HIGH PRESSURE HYDRAULIC FILTER SERVICE

TRANSMISSION FILTER SERVICE

PERIODIC REPLACEMENT OF COMPONENT PARTS FOR SAFETY DEVICES

Q - ALPHABETICAL INDEX

R - SYSTEM SCHEMATICS

HA204 AIR CIRCUIT PIPING

HA203 AIR SYSTEM SCHEMATIC

HH339 HYDRAULIC SYSTEM SCHEMATIC

HH340 HYDRAULIC SYSTEM PIPING

KT-T01 TRANSMISSION CROSS SECTION VIEW

HE462 ELECTRICAL WIRING SCHEMATIC

General

Language

EnglishModel of Truck

330MRegion

USAType of Document

Workshop ManualType of Truck

Rigid Dump TruckReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.