$20.00

Language

EnglishModel of Truck

SAA4D95LE-5-ARegion

WorldWideType of Document

Service ManualType of Truck

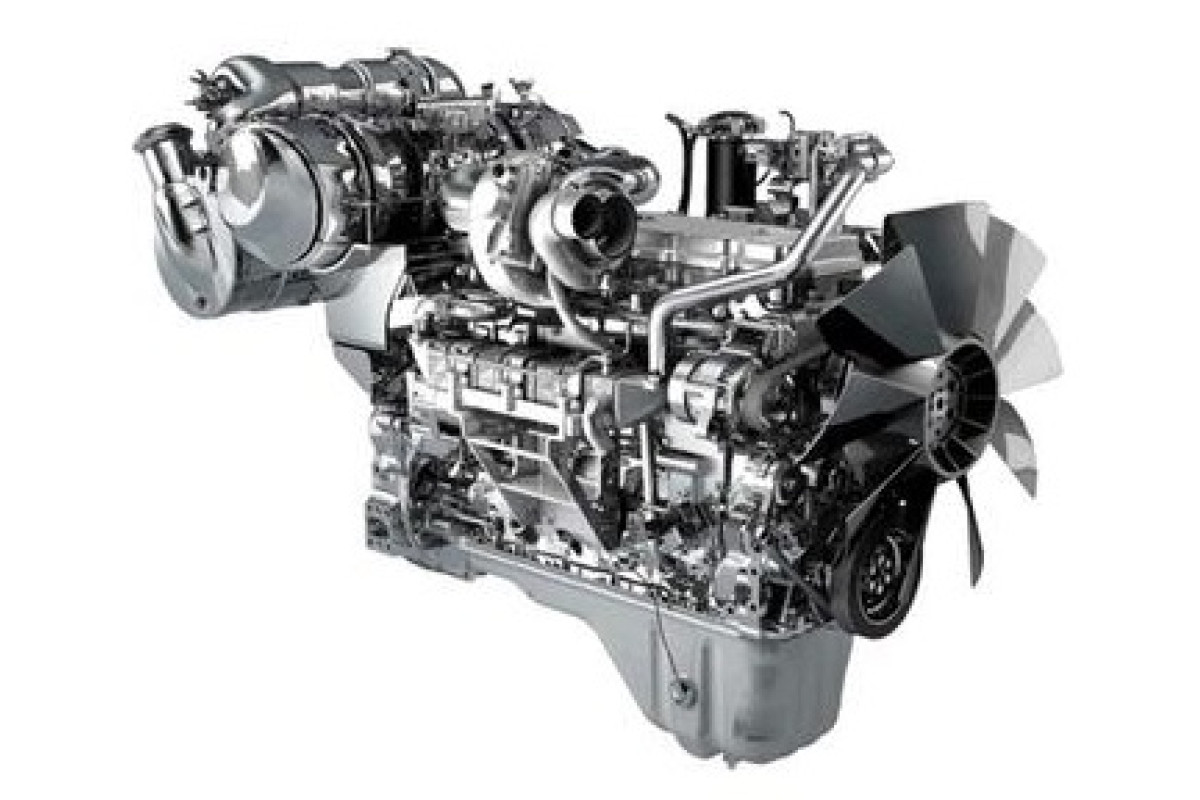

Diesel EngineIllustrated factory Service Manual for Komatsu Diesel Engines Models SAA4D95LE-5-A.

Applicable for Diesel Forklift Trucks Models FD40ZTU/F40TU/45TU/50ATU-10 SN. from 133001

This manual will assist you in diagnosing, analyses, testing, and repair for your diesel engine.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

SAA4D95LE-5-A

Format: PDF, 320 pages

Language: English

Table of Contents:

Index and foreword

Composition of shop manual

Table of contents

Safety notice

How to read the shop manual

Explanation of terms for maintenance standard

Handling of electric equipment and hydraulic component

Handling of connectors newly used for engines

How to read electric wire code

Precautions when carrying out operation

Method of disassembling and connecting push-pull type coupler

Standard tightening torque table

Conversion table

Specification

Outline

Specifications

General view

Weight table

Engine performance curves

Structure, function and maintenance standard

General structure

General structure

Air intake and exhaust system

Air intake and exhaust unit

Turbocharger

Engine unit

Cylinder head

Cylinder block

Cylinder

Main moving parts

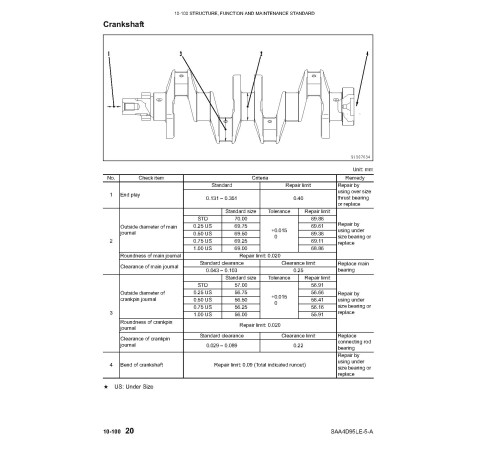

Crankshaft

Camshaft

Piston, piston ring and piston pin

Connecting rod

Flywheel and flywheel housing

Timing gear

Valve system

Valve, valve guide

Rocker arm shaft, push rod and tappet

Lubrication system

Lubrication system diagram

Oil pump

Regulator valve

Oil filter

Fuel system

Fuel system diagram

Supply pump

Fuel injection injector

Fuel filter

Common rail

Various sensor, actuator

Various connector

Cooling system

Cooling system diagram

Water pump

Cooling fan drive and thermostat

Electrical equipment

Starting and charging system electrical circuit diagram

Alternator

Starting motor

Starting aid

Engine controller

Standard value table

Standard service value table for testing, adjusting, and troubleshooting

Running-in standard and performance test standard

Testing and adjusting

Testing and adjusting tools list

Testing exhaust temperature

Adjusting valve clearance

Testing compression pressure

Testing blow-by pressure

Testing oil pressure

Handling fuel system parts

Releasing residual pressure in fuel system

Testing fuel pressure

Reduced cylinder mode operation

No-injection cranking

Testing leakage from pressure limiter and return rate from injector

Bleeding air from fuel circuit

Testing fuel system for leakage

Testing and adjusting alternator belt tension

Handling controller voltage circuit

Functions of troubleshooting tool and check of failure code

Troubleshooting

General information on troubleshooting

Points on troubleshooting

Failure code table

Information in troubleshooting table (E-mode)

Method of using troubleshooting charts (S-mode)

Troubleshooting for mechanical system (S-mode)

Troubleshooting for electrical system (E-mode)

Disassembly and assembly

How to read this manual

Coating materials list

Special tools list

General disassembly of engine

General assembly of engine

Disassembly and assembly procedure for fuel supply pump unit

DISASSEMBLY AND ASSEMBLY PROCEDURE FOR OIL SEAL UNITS

Applicable for Diesel Forklift Trucks Models FD40ZTU/F40TU/45TU/50ATU-10 SN. from 133001

This manual will assist you in diagnosing, analyses, testing, and repair for your diesel engine.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

SAA4D95LE-5-A

Format: PDF, 320 pages

Language: English

Table of Contents:

Index and foreword

Composition of shop manual

Table of contents

Safety notice

How to read the shop manual

Explanation of terms for maintenance standard

Handling of electric equipment and hydraulic component

Handling of connectors newly used for engines

How to read electric wire code

Precautions when carrying out operation

Method of disassembling and connecting push-pull type coupler

Standard tightening torque table

Conversion table

Specification

Outline

Specifications

General view

Weight table

Engine performance curves

Structure, function and maintenance standard

General structure

General structure

Air intake and exhaust system

Air intake and exhaust unit

Turbocharger

Engine unit

Cylinder head

Cylinder block

Cylinder

Main moving parts

Crankshaft

Camshaft

Piston, piston ring and piston pin

Connecting rod

Flywheel and flywheel housing

Timing gear

Valve system

Valve, valve guide

Rocker arm shaft, push rod and tappet

Lubrication system

Lubrication system diagram

Oil pump

Regulator valve

Oil filter

Fuel system

Fuel system diagram

Supply pump

Fuel injection injector

Fuel filter

Common rail

Various sensor, actuator

Various connector

Cooling system

Cooling system diagram

Water pump

Cooling fan drive and thermostat

Electrical equipment

Starting and charging system electrical circuit diagram

Alternator

Starting motor

Starting aid

Engine controller

Standard value table

Standard service value table for testing, adjusting, and troubleshooting

Running-in standard and performance test standard

Testing and adjusting

Testing and adjusting tools list

Testing exhaust temperature

Adjusting valve clearance

Testing compression pressure

Testing blow-by pressure

Testing oil pressure

Handling fuel system parts

Releasing residual pressure in fuel system

Testing fuel pressure

Reduced cylinder mode operation

No-injection cranking

Testing leakage from pressure limiter and return rate from injector

Bleeding air from fuel circuit

Testing fuel system for leakage

Testing and adjusting alternator belt tension

Handling controller voltage circuit

Functions of troubleshooting tool and check of failure code

Troubleshooting

General information on troubleshooting

Points on troubleshooting

Failure code table

Information in troubleshooting table (E-mode)

Method of using troubleshooting charts (S-mode)

Troubleshooting for mechanical system (S-mode)

Troubleshooting for electrical system (E-mode)

Disassembly and assembly

How to read this manual

Coating materials list

Special tools list

General disassembly of engine

General assembly of engine

Disassembly and assembly procedure for fuel supply pump unit

DISASSEMBLY AND ASSEMBLY PROCEDURE FOR OIL SEAL UNITS

General

Language

EnglishModel of Truck

SAA4D95LE-5-ARegion

WorldWideType of Document

Service ManualType of Truck

Diesel EngineReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.