$20.00

Language

EnglishModel of Truck

SA6D170E-3, SAA6D170E-3, SAA6D170E2-3, SAA6D170E-P910, SAA6D170E-P970Region

JapanType of Document

Workshop ManualType of Truck

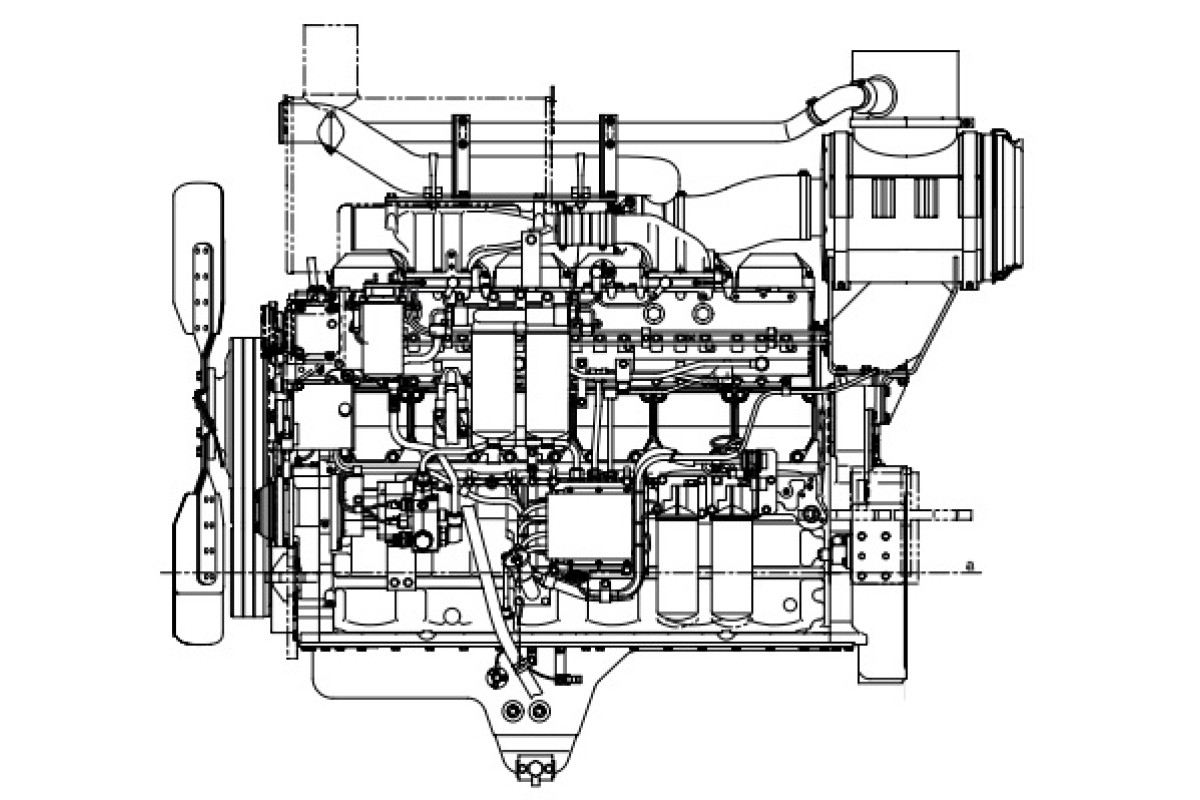

Diesel EngineIllustrated factory Workshop Manual for Komatsu Diesel Engines Models SA6D170E-3, SAA6D170E-3, SAA6D170E-P910, SAA6D170E-P970 and SAA6D170E2-3.

This manual will assist you in diagnosing, repairing, and adjusting for your diesel engine.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

SA6D170E-3

SAA6D170E-3

SAA6D170E-P910

SAA6D170E-P970

SAA6D170E2-3

Format: PDF, 454 pages

Language: English

Table of Contents:

GENERAL

APPLICABLE MACHINE

SPECIFICATIONS

OVERALL DRAWING

WEIGHT TABLE

ENGINE PERFORMANCE CURVE

STRUCTURE AND FUNCTION

INTAKE AND EXHAUST SYSTEM

ENGINE BODY

LUBRICATION SYSTEM

FUEL SYSTEM

COOLING SYSTEM

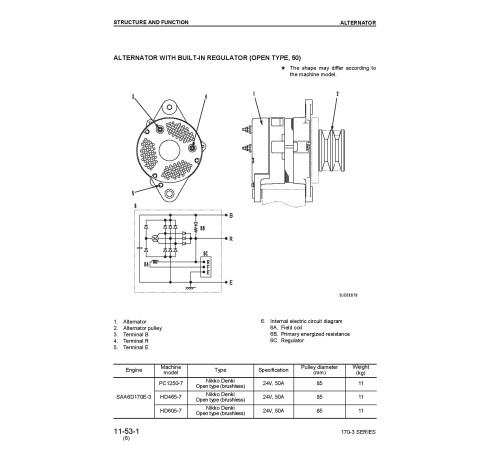

ELECTRICAL EQUIPMENT

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR TROULESHOOTING

STANDARD VALUE TABLE FOR ELECTRICAL PARTS

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

MEASURING EXHAUSTTEMPERATURE (OVERALL ENGINE)

TROUBLESHOOTING FOR INJECTOR

ADJUSTING VALVE CLEARANCE

ADJUSTING INJECTOR SET LOAD

MEASURING COMPRESSION PRESSURE

MEASURING BLOW-BY PRESSURE

MEASURING OIL PRESSURE

HANDLING EQUIPMENT IN FUEL CIRCUIT

MEASRING FUEL CICUIT PRESSURE

VIDUAL INSPECTION OF RETURN FUEL

BLEEDING AIR FROM FUEL CIRCUIT

ADJUSTING SPEED SENSOR

REPLACING AND ADJUSTING FAN BELT

TESTING AND ADJUSTING ALTERNATOR BELT TENSION

PRECAUTIONS WHEN OPERATION ENGINE AS AN INDVIDUAL PART

ARRANGEMENT OF CONTROL DEVICES AND ELECTRIC CIRCUIT FOR HPI

RUN-IN STANDARD

PERFORMANCE TEST STANDARDS

TROUBLESHOOTING OF MECHANICAL SYSTEM (S MODE)

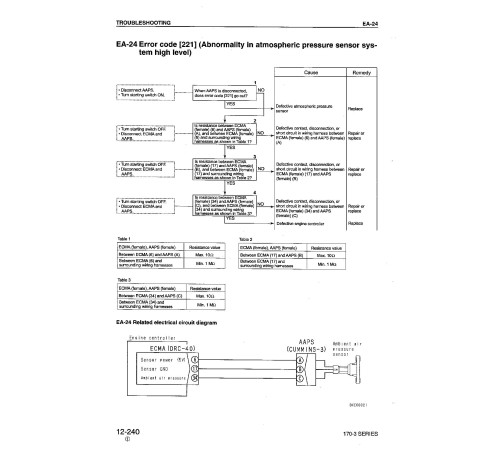

TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM OF ENGINE FOR CONSTRUCTION EQUIPMENT (EA MODE)

TROUBLESHOOTING OF CONTROLLER SYSTEM OF ENGING FOR GENERATOR EQUIPMENT

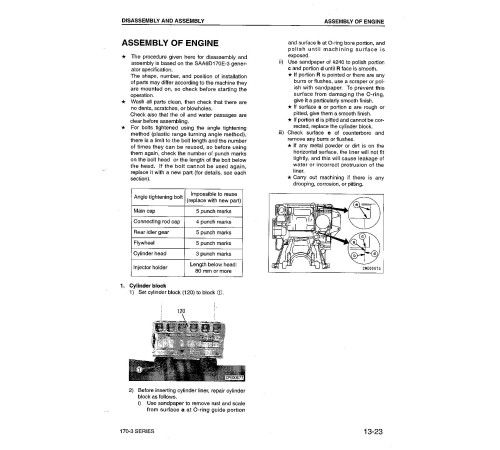

DISASSEMBLY AND ASSEMBLY

METHOD OF USING MANUAL

PRECAUTIONS WHEN CARRYING OUT OPERATION

SPECIAL TOOL LIST

DISASSEMBLY OF ENGINE

WASHING PARTS

MEASURING PARTS

MAINTENANCE STANDARD

NTAKE AND EXHAUST SYSTEM

ENGINE BODY

LUBRICATION SYSTEM

COOLING SYSTEM

REPAIR AND REPLACEMENT OF PARTS

TABLE OF SPECIAL TOOLS

TESTING AND INSPECTING CYINDER HEAD

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING

REPLACING VALVE SEAT INSERTS

PRESSURE TEST METHOD

REPLACING VALVE GUIDE

REPLACING CROSS HEAD GUIDE

GRINDING VALVE

TESTING AND INSPECTING CYLINDER BLOCK

GRINDING THE TOP SURFACE OF CYLINDER BLOCK

REPLACING MAIN BEARING CAP

REPLACING CAM BUSHING

TESTING AND INSPECTING CRANKSHAFT

CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION

REPAIRING CRANKSHAFT

TESTING AND INSPECTING OF CONNECTING ROD

REPLACING CRANKSHAFT GEAR

REPLACING CAMSHAFT GEAR

REPLACING FLYWHEEL RING GEAR

This manual will assist you in diagnosing, repairing, and adjusting for your diesel engine.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

SA6D170E-3

SAA6D170E-3

SAA6D170E-P910

SAA6D170E-P970

SAA6D170E2-3

Format: PDF, 454 pages

Language: English

Table of Contents:

GENERAL

APPLICABLE MACHINE

SPECIFICATIONS

OVERALL DRAWING

WEIGHT TABLE

ENGINE PERFORMANCE CURVE

STRUCTURE AND FUNCTION

INTAKE AND EXHAUST SYSTEM

ENGINE BODY

LUBRICATION SYSTEM

FUEL SYSTEM

COOLING SYSTEM

ELECTRICAL EQUIPMENT

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR TROULESHOOTING

STANDARD VALUE TABLE FOR ELECTRICAL PARTS

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

MEASURING EXHAUSTTEMPERATURE (OVERALL ENGINE)

TROUBLESHOOTING FOR INJECTOR

ADJUSTING VALVE CLEARANCE

ADJUSTING INJECTOR SET LOAD

MEASURING COMPRESSION PRESSURE

MEASURING BLOW-BY PRESSURE

MEASURING OIL PRESSURE

HANDLING EQUIPMENT IN FUEL CIRCUIT

MEASRING FUEL CICUIT PRESSURE

VIDUAL INSPECTION OF RETURN FUEL

BLEEDING AIR FROM FUEL CIRCUIT

ADJUSTING SPEED SENSOR

REPLACING AND ADJUSTING FAN BELT

TESTING AND ADJUSTING ALTERNATOR BELT TENSION

PRECAUTIONS WHEN OPERATION ENGINE AS AN INDVIDUAL PART

ARRANGEMENT OF CONTROL DEVICES AND ELECTRIC CIRCUIT FOR HPI

RUN-IN STANDARD

PERFORMANCE TEST STANDARDS

TROUBLESHOOTING OF MECHANICAL SYSTEM (S MODE)

TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM OF ENGINE FOR CONSTRUCTION EQUIPMENT (EA MODE)

TROUBLESHOOTING OF CONTROLLER SYSTEM OF ENGING FOR GENERATOR EQUIPMENT

DISASSEMBLY AND ASSEMBLY

METHOD OF USING MANUAL

PRECAUTIONS WHEN CARRYING OUT OPERATION

SPECIAL TOOL LIST

DISASSEMBLY OF ENGINE

WASHING PARTS

MEASURING PARTS

MAINTENANCE STANDARD

NTAKE AND EXHAUST SYSTEM

ENGINE BODY

LUBRICATION SYSTEM

COOLING SYSTEM

REPAIR AND REPLACEMENT OF PARTS

TABLE OF SPECIAL TOOLS

TESTING AND INSPECTING CYINDER HEAD

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING

REPLACING VALVE SEAT INSERTS

PRESSURE TEST METHOD

REPLACING VALVE GUIDE

REPLACING CROSS HEAD GUIDE

GRINDING VALVE

TESTING AND INSPECTING CYLINDER BLOCK

GRINDING THE TOP SURFACE OF CYLINDER BLOCK

REPLACING MAIN BEARING CAP

REPLACING CAM BUSHING

TESTING AND INSPECTING CRANKSHAFT

CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION

REPAIRING CRANKSHAFT

TESTING AND INSPECTING OF CONNECTING ROD

REPLACING CRANKSHAFT GEAR

REPLACING CAMSHAFT GEAR

REPLACING FLYWHEEL RING GEAR

General

Language

EnglishModel of Truck

SA6D170E-3, SAA6D170E-3, SAA6D170E2-3, SAA6D170E-P910, SAA6D170E-P970Region

JapanType of Document

Workshop ManualType of Truck

Diesel EngineReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.