$15.00

Language

EnglishModel of Truck

PC128UU-1Region

JapanType of Document

Operate and Maintenance manualType of Truck

Crawler ExcavatorIllustrated factory Operate and Maintenance manual for Komatsu Crawler Excavators Models PC128UU-1.

This manual will assist you in operating, and maintaining for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

PC128UU-1 (SN: 01001-02346)

Format: PDF, 264 pages

Language: English

Table of Contents:

INTRODUCTION

SAFETY INFORMATION

OVERVIEW OF THE EQUIPMENT

DESIGNATED USES

FEATURES OF THIS MACHINE

BREAK-IN

MEMO

LOCATION OF SERIAL NUMBER PLATES, AND FORM TO ENTER SERIAL NUMBER AND NAME OF THE DISTRIBUTOR

LOCATION OF SERIAL NUMBER

LOCATION OF ENGINE SERIAL NUMBER

FORM FOR ENTERING THE CYLINDER NUMBER AND THE KOMATSU DISTRIBUTOR

TABLE OF CONTENTS

SAFETY

BASIC PRECAUTIONS

PRECAUTIONS FOR OPERATING

BEFORE STARTING THE ENGINE

AFTER STARTING THE ENGINE

TRANSPORT THE VEHICLE

BATTERY

TOWING

BUCKET WITH HOOK

PRECAUTIONS FOR MAINTENANCE

PRIOR TO PERFORMING MAINTENANCE

DURING MAINTENANCE

WHERE SAFETY LABELS HAVE BEEN ATTACHED

WHERE SAFETY LABELS ARE LOCATED

OPERATION

THE NAME OF EACH PART

GENERAL DIAGRAM OF THE VEHICLE

GENERAL VIEW OF CONTROLS AND GAUGES

EXPLANATION OF EACH DEVICE

VEHICLE MONITOR PANEL

SWITCHES

CONTROL LEVERS / PEDALS

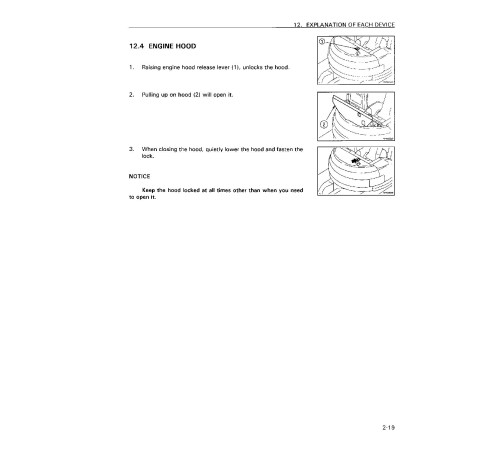

ENGINE HOOD

FRONT WINDOW

SLIDING DOOR

FUSE BOX

FUSIBLE LINK

LOCKING CAP AND COVERS

TOOL BOX

GREASE GUN HOLDER

CONTROLLERS

ASHTRAY (OPTIONAL)

REAR UNDER VIEW MIRROR (OPTIONAL)

USING THE CAR RADIO

USING THE AIR CONDITIONER

OPERATION

CHECKS BEFORE STARTING THE ENGINE

STARTING THE ENGINE

CHECKS AND TASKS TO BE PERFORMED AFTER STARTING THE ENGINE

MOVING THE MACHINE

STEERING THE MACHINE

STOPPING THE MACHINE

SWINGING

PROHIBITED ACTIONS WHILE OPERATING THE MACHINE

PRECAUTIONS DURING OPERATION

PRECAUTIONS WHEN CLIMBING OR DESCENDING SLOPES

EXTRICATING THE MACHINE FROM MUD

OPERATIONS THAT CAN BE PERFORMED WITH THE HYDRAULIC EXCAVATOR

CHANGING THE BUCKET

PARKING THE MACHINE

CHECKS AFTER COMPLETING OPERATION

STOPPING THE ENGINE

CHECKS AFTER THE ENGINE HAS BEEN STOPPED

LOCKING

USING THE 4 SYSTEMS

USING RUBBER TRACK SHOES (FOR MACHINES SPECIFIED FOR USE WITH RUBBER TRACKS)

TRANSPORTING

HOW TO LOAD AND UNLOAD THE VEHICLE

PRECAUTIONS WHEN CARRYING THINGS

PRECAUTIONS WHEN TRANSPORTING

HANDLING IN COLD WEATHER

PREPARATION FOR LOW TEMPERATURES

PRECAUTIONS AFTER COMPLETING OPERATIONS

PREPARING THE CAR HEATER

AFTER THE COLD WEATHER SEASON IS OVER

LONG-TERM STORAGE

BEFORE STORING THE MACHINE

DURING STORAGE

AFTER STORAGE

TROUBLESHOOTING

PHENOMENA THAT ARE NOT BREAKDOWNS

HOW TO TOW WITH THE MACHINE OR BE TOWED

HOW TO USE THE HOOK FOR TOWING LIGHT OBJECTS

PRECAUTIONS FOR SPECIAL JOB SITES

WHEN THE BATTERY IS DEAD

WHEN THIS PHENOMENON OCCURS

CHECKS AND MAINTENANCE

PRECAUTIONS IN PERFORMING CHECKS AND MAINTENANCE

BASIC MAINTENANCE

ESSENTIAL INFORMATION ON OIL, FUEL AND COOLANT

SUMMARY OF ELECTRICAL SYSTEM

SUMMARY OF HYDRAULIC SYSTEM

CONSUMABLE SUPPLIES

USAGE OF FUEL AND LUBRICATING GREASE ACCORDING TO AMBIENT TEMPERATURE

FUEL / OIL

COOLANT

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

LIST OF TOOLS NECESSARY

TORQUE TABLE

ABOUT REGULAR REPLACEMENT OF IMPORTANT COMPONENTS

LIST OF MAINTENANCE

MAINTENANCE SCHEDULE

SERVICE TIME WHEN USING HYDRAULIC BREAKERS

MAINTENANCE SCHEDULE

SERVICE PROCEDURES

INITIAL SERVICE AFTER 250 HOURS OF OPERATION

MAINTENANCE THAT IS NOT REGULARLY SCHEDULED

CHECKS BEFORE STARTING OPERATIONS

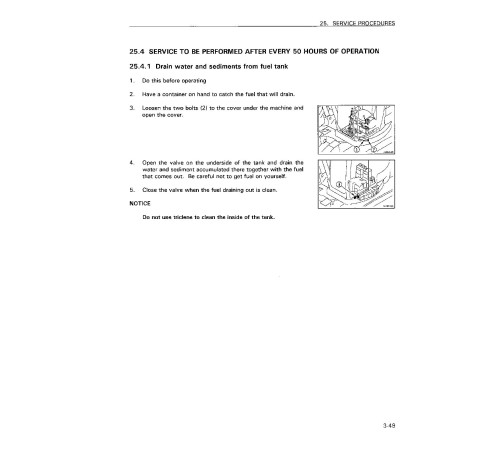

SERVICE TO BE PERFORMED AFTER EVERY 50 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 100 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 250 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 500 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 1000 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 2000 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 4000 HOURS OF OPERATION

INSPECTIONS REQUIRED

BEFORE BEGINNING WORK (CHECKS PRIOR TO STARTING OPERATIONS)

CHECKS BEFORE BEGINNING WORK (CHECKS PRIOR TO STARTING OPERATIONS)

SPECIFICATIONS

SPECIFICATIONS

OPTIONAL PARTS, ATTACHMENTS

GENERAL PRECAUTIONS

SAFETY PRECAUTIONS

PRECAUTIONS WHEN ATTACHMENTS ARE INSTALLED

USING THE BUCKET WITH HOOK

CHECKING THE BUCKET WITH HOOK ATTACHED FOR DAMAGE

OPERATIONS THAT SHOULD NOT BE PERFORMED

PRECAUTIONS DURING OPERATION

USING SEAT BELTS

SEAT BELTS

INFORMATION ON OPTIONAL ATTACHMENTS

INFORMATION ON OPTIONAL ATTACHMENTS

ATTACHMENT COMBINATION TABLE

SELECTING TRACKS

USING RUBBER PAD TRACKS

USING THE AUTOMATIC LEVELING DEVICE

USING THE MONO-BOOM

USING VEHICLES TO WHICH ATTACHMENTS CAN BE INSTALLED (MONO-BOOM)

SWITCHING OPERATION PATTERNS (ON MACHINES WHICH HAVE A PATTERN SWITCHING VALVE INSTALLED)

This manual will assist you in operating, and maintaining for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

PC128UU-1 (SN: 01001-02346)

Format: PDF, 264 pages

Language: English

Table of Contents:

INTRODUCTION

SAFETY INFORMATION

OVERVIEW OF THE EQUIPMENT

DESIGNATED USES

FEATURES OF THIS MACHINE

BREAK-IN

MEMO

LOCATION OF SERIAL NUMBER PLATES, AND FORM TO ENTER SERIAL NUMBER AND NAME OF THE DISTRIBUTOR

LOCATION OF SERIAL NUMBER

LOCATION OF ENGINE SERIAL NUMBER

FORM FOR ENTERING THE CYLINDER NUMBER AND THE KOMATSU DISTRIBUTOR

TABLE OF CONTENTS

SAFETY

BASIC PRECAUTIONS

PRECAUTIONS FOR OPERATING

BEFORE STARTING THE ENGINE

AFTER STARTING THE ENGINE

TRANSPORT THE VEHICLE

BATTERY

TOWING

BUCKET WITH HOOK

PRECAUTIONS FOR MAINTENANCE

PRIOR TO PERFORMING MAINTENANCE

DURING MAINTENANCE

WHERE SAFETY LABELS HAVE BEEN ATTACHED

WHERE SAFETY LABELS ARE LOCATED

OPERATION

THE NAME OF EACH PART

GENERAL DIAGRAM OF THE VEHICLE

GENERAL VIEW OF CONTROLS AND GAUGES

EXPLANATION OF EACH DEVICE

VEHICLE MONITOR PANEL

SWITCHES

CONTROL LEVERS / PEDALS

ENGINE HOOD

FRONT WINDOW

SLIDING DOOR

FUSE BOX

FUSIBLE LINK

LOCKING CAP AND COVERS

TOOL BOX

GREASE GUN HOLDER

CONTROLLERS

ASHTRAY (OPTIONAL)

REAR UNDER VIEW MIRROR (OPTIONAL)

USING THE CAR RADIO

USING THE AIR CONDITIONER

OPERATION

CHECKS BEFORE STARTING THE ENGINE

STARTING THE ENGINE

CHECKS AND TASKS TO BE PERFORMED AFTER STARTING THE ENGINE

MOVING THE MACHINE

STEERING THE MACHINE

STOPPING THE MACHINE

SWINGING

PROHIBITED ACTIONS WHILE OPERATING THE MACHINE

PRECAUTIONS DURING OPERATION

PRECAUTIONS WHEN CLIMBING OR DESCENDING SLOPES

EXTRICATING THE MACHINE FROM MUD

OPERATIONS THAT CAN BE PERFORMED WITH THE HYDRAULIC EXCAVATOR

CHANGING THE BUCKET

PARKING THE MACHINE

CHECKS AFTER COMPLETING OPERATION

STOPPING THE ENGINE

CHECKS AFTER THE ENGINE HAS BEEN STOPPED

LOCKING

USING THE 4 SYSTEMS

USING RUBBER TRACK SHOES (FOR MACHINES SPECIFIED FOR USE WITH RUBBER TRACKS)

TRANSPORTING

HOW TO LOAD AND UNLOAD THE VEHICLE

PRECAUTIONS WHEN CARRYING THINGS

PRECAUTIONS WHEN TRANSPORTING

HANDLING IN COLD WEATHER

PREPARATION FOR LOW TEMPERATURES

PRECAUTIONS AFTER COMPLETING OPERATIONS

PREPARING THE CAR HEATER

AFTER THE COLD WEATHER SEASON IS OVER

LONG-TERM STORAGE

BEFORE STORING THE MACHINE

DURING STORAGE

AFTER STORAGE

TROUBLESHOOTING

PHENOMENA THAT ARE NOT BREAKDOWNS

HOW TO TOW WITH THE MACHINE OR BE TOWED

HOW TO USE THE HOOK FOR TOWING LIGHT OBJECTS

PRECAUTIONS FOR SPECIAL JOB SITES

WHEN THE BATTERY IS DEAD

WHEN THIS PHENOMENON OCCURS

CHECKS AND MAINTENANCE

PRECAUTIONS IN PERFORMING CHECKS AND MAINTENANCE

BASIC MAINTENANCE

ESSENTIAL INFORMATION ON OIL, FUEL AND COOLANT

SUMMARY OF ELECTRICAL SYSTEM

SUMMARY OF HYDRAULIC SYSTEM

CONSUMABLE SUPPLIES

USAGE OF FUEL AND LUBRICATING GREASE ACCORDING TO AMBIENT TEMPERATURE

FUEL / OIL

COOLANT

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

LIST OF TOOLS NECESSARY

TORQUE TABLE

ABOUT REGULAR REPLACEMENT OF IMPORTANT COMPONENTS

LIST OF MAINTENANCE

MAINTENANCE SCHEDULE

SERVICE TIME WHEN USING HYDRAULIC BREAKERS

MAINTENANCE SCHEDULE

SERVICE PROCEDURES

INITIAL SERVICE AFTER 250 HOURS OF OPERATION

MAINTENANCE THAT IS NOT REGULARLY SCHEDULED

CHECKS BEFORE STARTING OPERATIONS

SERVICE TO BE PERFORMED AFTER EVERY 50 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 100 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 250 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 500 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 1000 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 2000 HOURS OF OPERATION

SERVICE TO BE PERFORMED AFTER EVERY 4000 HOURS OF OPERATION

INSPECTIONS REQUIRED

BEFORE BEGINNING WORK (CHECKS PRIOR TO STARTING OPERATIONS)

CHECKS BEFORE BEGINNING WORK (CHECKS PRIOR TO STARTING OPERATIONS)

SPECIFICATIONS

SPECIFICATIONS

OPTIONAL PARTS, ATTACHMENTS

GENERAL PRECAUTIONS

SAFETY PRECAUTIONS

PRECAUTIONS WHEN ATTACHMENTS ARE INSTALLED

USING THE BUCKET WITH HOOK

CHECKING THE BUCKET WITH HOOK ATTACHED FOR DAMAGE

OPERATIONS THAT SHOULD NOT BE PERFORMED

PRECAUTIONS DURING OPERATION

USING SEAT BELTS

SEAT BELTS

INFORMATION ON OPTIONAL ATTACHMENTS

INFORMATION ON OPTIONAL ATTACHMENTS

ATTACHMENT COMBINATION TABLE

SELECTING TRACKS

USING RUBBER PAD TRACKS

USING THE AUTOMATIC LEVELING DEVICE

USING THE MONO-BOOM

USING VEHICLES TO WHICH ATTACHMENTS CAN BE INSTALLED (MONO-BOOM)

SWITCHING OPERATION PATTERNS (ON MACHINES WHICH HAVE A PATTERN SWITCHING VALVE INSTALLED)

General

Language

EnglishModel of Truck

PC128UU-1Region

JapanType of Document

Operate and Maintenance manualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.