$15.00

Language

EnglishModel of Truck

PC240LC-10Region

USAType of Document

Operate and Maintenance manualType of Truck

Crawler ExcavatorIllustrated factory Operate and Maintenance manual for Komatsu Crawler Excavators Models PC240LC-10.

This manual will assist you in operating, and maintaining for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

PC240LC-10 (SN: A20001-)

Format: PDF, 450 pages

Language: English

Table of Contents:

FORWARD

SAFETY INFORMATION

Safety Labels

INTRODUCTION

Directions of Machine

Visibility from Operators Seat

Breaking-in The New Machine

Product Information

Service Meter Location

Your Machine Serial Numbers And Distributor

Engine Acronyms

TABLE OF CONTENTS

SAFETY LABELS

Location Of Safety Labels

Safety Labels

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

Precautions Before Starting Operation

Preparations For Safe Operation

Clothing And Personal Protective Items

Keep Machine Clean

Keep Operator's Compartment Clean

Fire Extinguisher And First Aid Kit

Safety Equipment

If Problems Are Found

Fire Prevention And Explosion Prevention

Action If Fire Occurs

Handrails and Steps

Mounting And Dismounting

No Persons On Attachments

Leaving Operator's Seat With Lock

Emergency Exit From Operator's Cab

Do Not Get Caught In Work Equipment

Precautions Related To Protective Structures

Falling Objects, Flying Objects And Intruding Objects Prevention

Unauthorized Modification

Precautions Related To Attachments And Options

Precautions Related To Cab Glass

Precautions When Running Engine Inside Building

Safety At Jobsite

Working On Loose Ground

Distance To High Voltage Cables

Ensure Good Visibility

Signalman's Signal And Signs

Asbestos Dust Hazard Prevention

SAFETY MACHINE OPERATION

Starting Engine

Operation

TRANSPORTATION

Loading and Unloading

Shipping the Machine

TOWING

Safety Rules For Towing

LIFTING OBJECTS WITH BUCKET

Safety Rules For Lifting Objects

SAFETY MAINTENANCE INFORMATION

Warning Tag

Keep Work Place Clean And Tidy

Select Suitable Place For Inspection And Maintenance

Only Authorized Personnel

Appoint Leader When Working With Others

Stop Engine Before Carrying Out Maintenance

Precautions When Working At High Places

Two Workers For Maintenance When Engine Is Running

Attachments

Work On Machine

Work Under The Machine

Proper Tools

Battery Disconnect Switch

Removing Battery Terminals

Welding

Battery

When Using Hammer

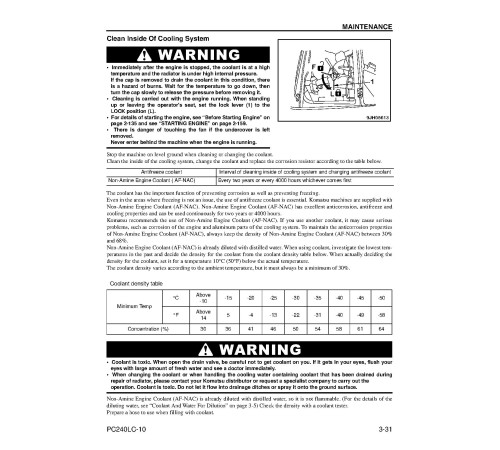

Precautions With High-temperature Coolant

Precautions With High-temperature Oil

Safety Rules For High-pressure Oil

Precaution For High Voltage

Noise

Safety First When Using High-pressure Grease To Adjust Track Tension

Do Not Disassemble Recoil Springs

Accumulator

Handling Gas Spring

Compressed Air

Air Conditioner Maintenance

Waste Materials

Select Window Washer Fluid

Personnel

Periodic Replacement Of Safety Critical Parts

MACHINE VIEW ILLUSTRATIONS

Overall Machine View

General View of Cab

CONTROLS AND GAUGES

Machine Monitor

EXPLANATION OF COMPONENTS

Machine Monitor

Monitor Setting

SWITCHES

Starting Switch

Fuel Control Dial

Cigarette Lighter

Swing Lock Switch

Lamp Switch

Horn Switch

One Touch Power Max. Switch

Room Lamp Switch

Emergency Pump Drive Switch

Swing Brake Cancel Switch

Ceiling Window Wiper Switch

Seat Heater Switch

Engine Shutdown Secondary Switch

CONTROL LEVERS AND PEDALS

Lock Lever

Travel Levers

Work Equipment Control Lever

ROOF WINDOW

WINDSHIELD

EMERGENCY ESCAPE HAMMER

DOOR LOCK

CAB DOOR HINGE

ENGINE HOOD

When Opening (Normal Case: Intermediate Lock Position)

When Closing (Normal Case: Intermediate Lock Position)

CAPS AND COVERS WITH LOCK

Open and Close Caps with Lock

Open and Close Covers with Lock

Lock and Unlock Engine Hood

Lock and Unlock Cab Door

DRINK BOX

MAGAZINE BOX

CUP HOLDER

ASHTRAY

AIR CONDITIONER CONTROLS

Air Conditioner Control Panel

Method of Operation

Rules for Using Air Conditioner

Air Conditioner Maintenance

RADIO

Control Panel

Operation Method

AUXILIARY ELECTRIC POWER

24 V Power Source

12 V Power Source

FUSE

FUSIBLE LINK

TOOL BOX

GREASE GUN HOLDER

FIRE EXTINGUISHER

BATTERY DISCONNECT SWITCH

SYSTEM OPERATING LAMP

HANDLING KOMATSU DIESEL PARTICULATE FILTER (KDPF)

Operation Procedure of Manual Stationary Regeneration

HANDLING MACHINES EQUIPPED WITH KOMTRAX

Basic Precautions

MACHINE OPERATIONS AND CONTROLS

Before Starting Engine

Seat Belt Inspection

Seat Belt

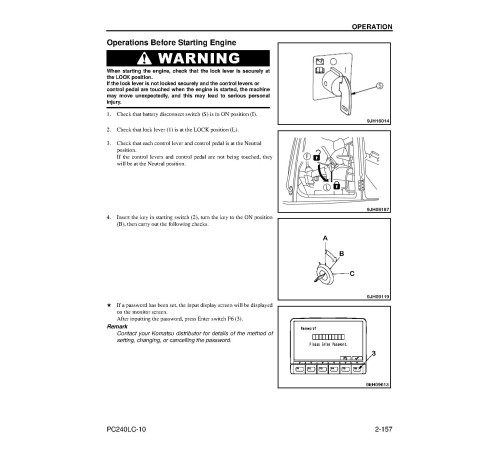

Operations Before Starting Engine

STARTING ENGINE

Turbo Protect Function

AFTER STARTING ENGINE

Engine Warm Up

Hydraulic System Warm-Up

Operation After Completion Of Warming-Up Operation

STOPPING THE ENGINE

MACHINE OPERATION

Preparations for Moving the Machine

Moving Machine Forward

Moving Machine Backward

Stopping Machine

STEERING THE MACHINE

Steering

SWINGING

WORK EQUIPMENT CONTROLS AND OPERATIONS

WORKING MODE

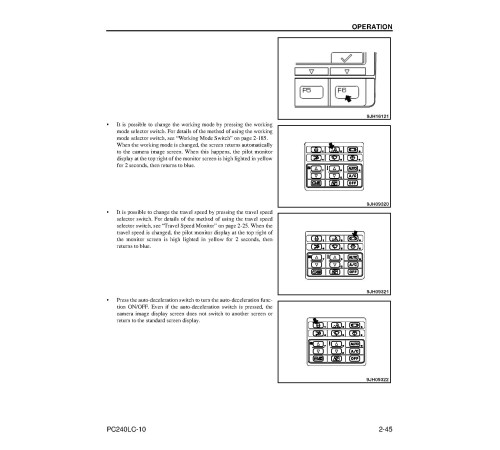

Working Mode Switch

One-Touch Power Max. Switch

PROHIBITED OPERATIONS

GENERAL OPERATION INFORMATION

Traveling

High Speed Travel

Permissible Water Depth

TRAVELING ON SLOPES

ESCAPE FROM MUD

Track on One Side Stuck

Tracks on Both Sides Stuck

RECOMMENDED APPLICATIONS

Backhoe Work

Shovel Work

Ditching Work

Loading Work

BUCKET REPLACEMENT AND INVERSION

Replacement

Inversion

PARKING MACHINE

MACHINE INSPECTION AFTER DAILY WORK

LOCKING

TRANSPORTATION

Transportation Procedure

Loading And Unloading With Trailer

LONG DISTANCE TRANSPORT MODE

Normal Mode Display

Long Distance Transport Mode Display

LIFTING MACHINE

Standard Specification Machines

COLD WEATHER OPERATION

Cold Weather Operation Information

AFTER DAILY WORK COMPLETION

AFTER COLD WEATHER SEASON

LONG TERM STORAGE

Before Storage

During Storage

After Storage

Starting Machine After Long-term Storage

TROUBLES AND ACTIONS

Running Out Of Fuel

Phenomena That Are Not Failures

Towing The Machine

Lightweight Towing Hole

Severe Job Condition

Discharged Battery

OTHER TROUBLE

Electrical System

Chassis

Engine

Electronic Control System

MAINTENANCE INFORMATION

OUTLINE OF SERVICE

Handling Oil, Fuel, Coolant, And Performing Oil Clinic

Electric System Maintenance

WEAR PARTS

Wear Parts List

RECOMMENDED FUEL, COOLANT, AND LUBRICANT

Lubrication Chart

Fuel, Coolant, and Lubricants to Match the Ambient Temperature

KDPF (Komatsu Diesel Particulate Filter)

Recommended Brands, Recommended Quality For Products Other Than Komatsu Genuine Oil

TORQUE SPECIFICATIONS

Torque List

SAFETY CRITICAL PARTS

Safety Critical Parts List

MAINTENANCE SCHEDULE

Maintenance Schedule Table

Maintenance Interval For Hydraulic Breaker

MAINTENANCE PROCEDURE

Initial 10 Hours Maintenance

Initial 250 Hours Maintenance (Only After The First 250 Hours)

Initial 500 Hours Maintenance (Only After The First 500 Hours)

When Required

Check Before Starting

Every 100 Hours Maintenance

Every 250 Hours Maintenance

Every 500 Hours Maintenance

Every 1000 Hours Maintenance

Every 2000 Hours Maintenance

Every 4000 Hours Maintenance

Every 4500 Hours Maintenance

Every 5000 Hours Maintenance

Every 8000 Hours Maintenance

SPECIFICATIONS

GENERAL PRECAUTIONS FOR SAFETY

Precautions When Selecting

Read The Operation and Maintenance Manual Thoroughly

Precautions When Removing Or Installing

Precautions When Using

BUCKET WITH HOOK

Hook Condition

Prohibited Operations

CHANGING DIRECTION OF THE MACHINE

Straight Travel (Option)

CHANGING MACHINE CONTROL PATTERN

Control Pattern Change Procedure

MACHINE READY FOR ATTACHMENT

Locations

HYDRAULIC CIRCUIT

Switching Hydraulic Circuit

Hydraulic Circuit Connection

Oil Flow Path

Replace Additional Breaker Filter Element

Replace Additional Breaker Pilot Filter Element

ATTACHMENT REMOVAL AND INSTALLATION

Attachment Removal

Attachment Installation

ATTACHMENT OPERATIONS

When Using Breaker

When Using General Attachment Such as Crusher

LONG TERM STORAGE

Specifications

Attachment Guide

Attachment Combinations

TRACK SHOES SELECTION

BUCKET TEETH SELECTION

Selection Guide for Horizontal or Vertical Pin Type Tooth

HANDLING OF RUBBER PAD SHOE AND ROAD LINER

Check Road Liner

Handling Trapezoidal Bucket

Digging Work

HANDLING EXTENSION ARM

HANDLING CLAMSHELL BUCKET

RECOMMENDED ATTACHMENT OPERATIONS

Hydraulic Breaker

Prohibited Usage

This manual will assist you in operating, and maintaining for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

PC240LC-10 (SN: A20001-)

Format: PDF, 450 pages

Language: English

Table of Contents:

FORWARD

SAFETY INFORMATION

Safety Labels

INTRODUCTION

Directions of Machine

Visibility from Operators Seat

Breaking-in The New Machine

Product Information

Service Meter Location

Your Machine Serial Numbers And Distributor

Engine Acronyms

TABLE OF CONTENTS

SAFETY LABELS

Location Of Safety Labels

Safety Labels

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

Precautions Before Starting Operation

Preparations For Safe Operation

Clothing And Personal Protective Items

Keep Machine Clean

Keep Operator's Compartment Clean

Fire Extinguisher And First Aid Kit

Safety Equipment

If Problems Are Found

Fire Prevention And Explosion Prevention

Action If Fire Occurs

Handrails and Steps

Mounting And Dismounting

No Persons On Attachments

Leaving Operator's Seat With Lock

Emergency Exit From Operator's Cab

Do Not Get Caught In Work Equipment

Precautions Related To Protective Structures

Falling Objects, Flying Objects And Intruding Objects Prevention

Unauthorized Modification

Precautions Related To Attachments And Options

Precautions Related To Cab Glass

Precautions When Running Engine Inside Building

Safety At Jobsite

Working On Loose Ground

Distance To High Voltage Cables

Ensure Good Visibility

Signalman's Signal And Signs

Asbestos Dust Hazard Prevention

SAFETY MACHINE OPERATION

Starting Engine

Operation

TRANSPORTATION

Loading and Unloading

Shipping the Machine

TOWING

Safety Rules For Towing

LIFTING OBJECTS WITH BUCKET

Safety Rules For Lifting Objects

SAFETY MAINTENANCE INFORMATION

Warning Tag

Keep Work Place Clean And Tidy

Select Suitable Place For Inspection And Maintenance

Only Authorized Personnel

Appoint Leader When Working With Others

Stop Engine Before Carrying Out Maintenance

Precautions When Working At High Places

Two Workers For Maintenance When Engine Is Running

Attachments

Work On Machine

Work Under The Machine

Proper Tools

Battery Disconnect Switch

Removing Battery Terminals

Welding

Battery

When Using Hammer

Precautions With High-temperature Coolant

Precautions With High-temperature Oil

Safety Rules For High-pressure Oil

Precaution For High Voltage

Noise

Safety First When Using High-pressure Grease To Adjust Track Tension

Do Not Disassemble Recoil Springs

Accumulator

Handling Gas Spring

Compressed Air

Air Conditioner Maintenance

Waste Materials

Select Window Washer Fluid

Personnel

Periodic Replacement Of Safety Critical Parts

MACHINE VIEW ILLUSTRATIONS

Overall Machine View

General View of Cab

CONTROLS AND GAUGES

Machine Monitor

EXPLANATION OF COMPONENTS

Machine Monitor

Monitor Setting

SWITCHES

Starting Switch

Fuel Control Dial

Cigarette Lighter

Swing Lock Switch

Lamp Switch

Horn Switch

One Touch Power Max. Switch

Room Lamp Switch

Emergency Pump Drive Switch

Swing Brake Cancel Switch

Ceiling Window Wiper Switch

Seat Heater Switch

Engine Shutdown Secondary Switch

CONTROL LEVERS AND PEDALS

Lock Lever

Travel Levers

Work Equipment Control Lever

ROOF WINDOW

WINDSHIELD

EMERGENCY ESCAPE HAMMER

DOOR LOCK

CAB DOOR HINGE

ENGINE HOOD

When Opening (Normal Case: Intermediate Lock Position)

When Closing (Normal Case: Intermediate Lock Position)

CAPS AND COVERS WITH LOCK

Open and Close Caps with Lock

Open and Close Covers with Lock

Lock and Unlock Engine Hood

Lock and Unlock Cab Door

DRINK BOX

MAGAZINE BOX

CUP HOLDER

ASHTRAY

AIR CONDITIONER CONTROLS

Air Conditioner Control Panel

Method of Operation

Rules for Using Air Conditioner

Air Conditioner Maintenance

RADIO

Control Panel

Operation Method

AUXILIARY ELECTRIC POWER

24 V Power Source

12 V Power Source

FUSE

FUSIBLE LINK

TOOL BOX

GREASE GUN HOLDER

FIRE EXTINGUISHER

BATTERY DISCONNECT SWITCH

SYSTEM OPERATING LAMP

HANDLING KOMATSU DIESEL PARTICULATE FILTER (KDPF)

Operation Procedure of Manual Stationary Regeneration

HANDLING MACHINES EQUIPPED WITH KOMTRAX

Basic Precautions

MACHINE OPERATIONS AND CONTROLS

Before Starting Engine

Seat Belt Inspection

Seat Belt

Operations Before Starting Engine

STARTING ENGINE

Turbo Protect Function

AFTER STARTING ENGINE

Engine Warm Up

Hydraulic System Warm-Up

Operation After Completion Of Warming-Up Operation

STOPPING THE ENGINE

MACHINE OPERATION

Preparations for Moving the Machine

Moving Machine Forward

Moving Machine Backward

Stopping Machine

STEERING THE MACHINE

Steering

SWINGING

WORK EQUIPMENT CONTROLS AND OPERATIONS

WORKING MODE

Working Mode Switch

One-Touch Power Max. Switch

PROHIBITED OPERATIONS

GENERAL OPERATION INFORMATION

Traveling

High Speed Travel

Permissible Water Depth

TRAVELING ON SLOPES

ESCAPE FROM MUD

Track on One Side Stuck

Tracks on Both Sides Stuck

RECOMMENDED APPLICATIONS

Backhoe Work

Shovel Work

Ditching Work

Loading Work

BUCKET REPLACEMENT AND INVERSION

Replacement

Inversion

PARKING MACHINE

MACHINE INSPECTION AFTER DAILY WORK

LOCKING

TRANSPORTATION

Transportation Procedure

Loading And Unloading With Trailer

LONG DISTANCE TRANSPORT MODE

Normal Mode Display

Long Distance Transport Mode Display

LIFTING MACHINE

Standard Specification Machines

COLD WEATHER OPERATION

Cold Weather Operation Information

AFTER DAILY WORK COMPLETION

AFTER COLD WEATHER SEASON

LONG TERM STORAGE

Before Storage

During Storage

After Storage

Starting Machine After Long-term Storage

TROUBLES AND ACTIONS

Running Out Of Fuel

Phenomena That Are Not Failures

Towing The Machine

Lightweight Towing Hole

Severe Job Condition

Discharged Battery

OTHER TROUBLE

Electrical System

Chassis

Engine

Electronic Control System

MAINTENANCE INFORMATION

OUTLINE OF SERVICE

Handling Oil, Fuel, Coolant, And Performing Oil Clinic

Electric System Maintenance

WEAR PARTS

Wear Parts List

RECOMMENDED FUEL, COOLANT, AND LUBRICANT

Lubrication Chart

Fuel, Coolant, and Lubricants to Match the Ambient Temperature

KDPF (Komatsu Diesel Particulate Filter)

Recommended Brands, Recommended Quality For Products Other Than Komatsu Genuine Oil

TORQUE SPECIFICATIONS

Torque List

SAFETY CRITICAL PARTS

Safety Critical Parts List

MAINTENANCE SCHEDULE

Maintenance Schedule Table

Maintenance Interval For Hydraulic Breaker

MAINTENANCE PROCEDURE

Initial 10 Hours Maintenance

Initial 250 Hours Maintenance (Only After The First 250 Hours)

Initial 500 Hours Maintenance (Only After The First 500 Hours)

When Required

Check Before Starting

Every 100 Hours Maintenance

Every 250 Hours Maintenance

Every 500 Hours Maintenance

Every 1000 Hours Maintenance

Every 2000 Hours Maintenance

Every 4000 Hours Maintenance

Every 4500 Hours Maintenance

Every 5000 Hours Maintenance

Every 8000 Hours Maintenance

SPECIFICATIONS

GENERAL PRECAUTIONS FOR SAFETY

Precautions When Selecting

Read The Operation and Maintenance Manual Thoroughly

Precautions When Removing Or Installing

Precautions When Using

BUCKET WITH HOOK

Hook Condition

Prohibited Operations

CHANGING DIRECTION OF THE MACHINE

Straight Travel (Option)

CHANGING MACHINE CONTROL PATTERN

Control Pattern Change Procedure

MACHINE READY FOR ATTACHMENT

Locations

HYDRAULIC CIRCUIT

Switching Hydraulic Circuit

Hydraulic Circuit Connection

Oil Flow Path

Replace Additional Breaker Filter Element

Replace Additional Breaker Pilot Filter Element

ATTACHMENT REMOVAL AND INSTALLATION

Attachment Removal

Attachment Installation

ATTACHMENT OPERATIONS

When Using Breaker

When Using General Attachment Such as Crusher

LONG TERM STORAGE

Specifications

Attachment Guide

Attachment Combinations

TRACK SHOES SELECTION

BUCKET TEETH SELECTION

Selection Guide for Horizontal or Vertical Pin Type Tooth

HANDLING OF RUBBER PAD SHOE AND ROAD LINER

Check Road Liner

Handling Trapezoidal Bucket

Digging Work

HANDLING EXTENSION ARM

HANDLING CLAMSHELL BUCKET

RECOMMENDED ATTACHMENT OPERATIONS

Hydraulic Breaker

Prohibited Usage

General

Language

EnglishModel of Truck

PC240LC-10Region

USAType of Document

Operate and Maintenance manualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.