Model

CEBM005905SKU

40055Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA6D102E-2: SEBM010023

$25.00

Language

EnglishModel of Truck

PC270LC-7LRegion

USAType of Document

Workshop ManualType of Truck

Crawler ExcavatorIllustrated factory Workshop Manual for Komatsu Crawler Excavators Models PC270LC-7L.

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

PC270LC-7L (SN: A86001-)

Format: PDF, 838 pages

Language: English

Table of Contents:

SAFETY

Safety Notice

GENERAL

HOW TO READ THE SHOP MANUAL

Volumes

Distribution And Updating

Filing Method

Revised Edition Mark

Revisions

Symbols

HOISTING INSTRUCTIONS

Hoisting

Wire Ropes

PUSH-PULL TYPE COUPLER

COATING MATERIALS

STANDARD TIGHTENING TORQUE

Standard Tightening Torque Of Bolts And Nuts

Tightening Torque Of Split Flange Bolts

Tightening Torque For Flared Nuts

Table Of Tightening Torques For O-ring Boss Piping Joints

Table Of Tightening Torques For O-ring Boss Plugs

Tightening Torque For 102 And 114 Engine Series

Tightening Torque Table For Hoses (Taper Seal Type And Face Seal Type)

ELECTRIC WIRE CODE

Classification By Thickness

Classification By Color And Code

CONVERSION TABLES

Method Of Using The Conversion Table

SPECIFICATION DIMENSION DRAWINGS

Dimensions

Working Ranges

SPECIFICATIONS

WEIGHT TABLE

FUEL, COOLANT AND LUBRICANTS

Recommended Brands, Recommended Quality For Products Other Than Komatsu Genuine Oil

ENGINE RELATED PARTS

RADIATOR . OIL COOLER . AFTERCOOLER

POWER TRAIN

FINAL DRIVE

SWING MACHINERY

SWING CIRCLE

TRACK FRAME . RECOIL SPRING

IDLER

CARRIER ROLLER

TRACK ROLLER

TRACK SHOE

TRIPLE GROUSER SHOE

HYDRAULIC EQUIPMENT LAYOUT DRAWING

HYDRAULIC TANK

HYDRAULIC PUMP

HPV95+95

LS valve

PC Valve

LS(PC)-EPC Valve

CONTROL VALVE

SELF PRESSURE REDUCING VALVE

Main Relief Valve

VARIABLE PRESSURE COMPENSATION VALVE

CLSS

SWING MOTOR

Relief Valve Portion

REVERSE PREVENTION VALVE

CENTER SWIVEL JOINT

TRAVEL MOTOR

Motor Operation

Parking Brake Operation

Brake Valve Operation

TRAVEL JUNCTION VALVE

TRAVEL PPC SHUTTLE VALVE

VALVE CONTROL

WORK EQUIPMENT . SWING PPC VALVE

TRAVEL PPC VALVE

SERVICE PPC VALVE

SOLENOID VALVE

PPC ACCUMULATOR

RETURN OIL FILTER

BOOM HYDRAULIC DRIFT PREVENTION VALVE

LIFT CHECK VALVE

ATTACHMENT CIRCUIT SELECTOR VALVE

HYDRAULIC CYLINDERS

Boom Cylinder

Arm Cylinder

Bucket Cylinder

WORK EQUIPMENT

Hours

Hours

Dimension Of Arm

Dimension Of Bucket

AIR CONDITIONER

Piping

ENGINE CONTROL

Fuel Control Dial

Engine Throttle And Pump Controller

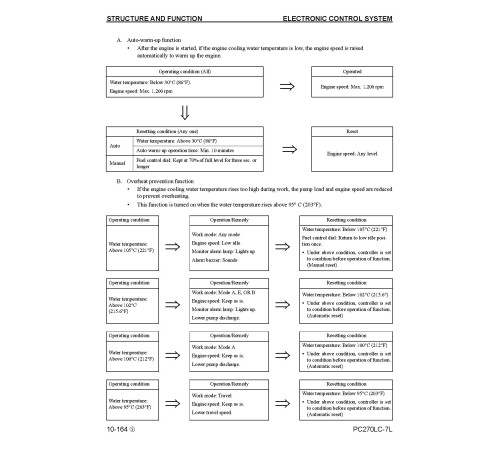

ELECTRONIC CONTROL SYSTEM

Total System Diagram

MULTI MONITOR SYSTEM

Monitor Panel

Monitor Control, Display Portion Monitor Portion

Maintenance Function

SEGMENT MONITOR SYSTEM

Monitor panel

SENSORS

Engine Oil Level Sensor

Engine Oil Pressure Sensor (For Low Pressure)

Coolant Temperature Sensor

Hydraulic Oil Temperature Sensor

Fuel Level Sensor

Air Cleaner Clogging Sensor

STANDARD VALUE TABLES

Engine

Chassis

SERVICE TOOLS

ENGINE

Engine Speed

Exhaust Gas Color

Valve Clearance

Compression Pressure

Blow-by Pressure

Fuel Injection Timing

Engine Oil Pressure

Engine Speed Sensor

Defective Cylinder

BELT TENSION - AIR COMPRESSOR

ENGINE CONTROL SYSTEM FAILURE

SWING CIRCLE BEARINGS

TRACK SHOE TENSION

SPROCKET

OIL PRESSURE

Work Equipment, Swing And Travel

Control Circuit

Pump PC Control Circuit

Pump LS Control Circuit

Solenoid Valve Output Pressure

PPC Valve Output Pressure

WORK EQUIPMENT AND SWING PPC VALVE

WORK EQUIPMENT - HYDRAULIC DRIFT

RELEASING PRESSURE IN HYDRAULIC CIRCUIT

OIL LEAKAGE

AIR BLEEDING OF VARIOUS PARTS

DIODE INSPECTION PROCEDURES

MULTI-MONITOR PANEL

Monitor Panel Functions - Conventional And Special

Conventional Function: Operator`s Menu

Special Function: Service Menu

Operator`s Menu And Display (Outline)

Table For Service And Failure Code Numbers

Service Menu

SEGMENTS MONITOR PANEL - SPECIAL FUNCTIONS

Ordinary functions and special functions of monitor panel

Display of operator menu

Operation and display of service menu

ELECTRICAL SYSTEM TROUBLESHOOTING

PM TUNE UP SERVICE

POINTS TO REMEMBER WHEN TROUBLESHOOTING

SEQUENCE OF EVENTS IN TROUBLESHOOTING

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

CHECKS BEFORE TROUBLESHOOTING

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

Classification Of Troubleshooting

Steps For Troubleshooting

Failure-looking Phenomenon And Troubleshooting No.

ELECTRICAL CIRCUIT DIAGRAM SYSTEM

Connector Table

Connector Location Diagram

ELECTRICAL CIRCUIT DIAGRAMS

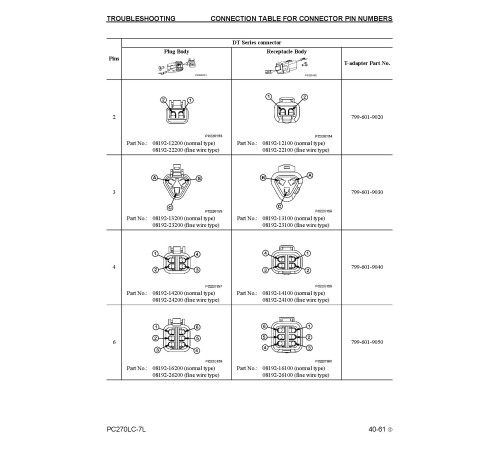

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

T-BRANCH BOX AND T-BRANCH TABLE

BEFORE TROUBLESHOOTING FOR DISPLAYED CODE

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM

Points To Remember If Abnormality Returns To Normal By Itself

User Code Memory Retention Function

Information In Troubleshooting Table

E101 - ABNORMAL DATA IN ERROR HISTORY

E112 - SHORT IN WINDSHIELD WIPER MOTOR DRIVE FORWARD ROTATION

E113 - SHORT IN WINDSHIELD WIPER MOTOR DRIVE REVERSE ROTATION

E114 - SHORT OR OPEN IN WINDOW WASHER SYSTEM

S/N A86001-A86216

S/N A86217-UP

E115 - ABNORMAL WINDSHIELD WIPER MOTION

E116 - ABNORMALITY IN PARKING WIPER ARM

E201 - SHORT OR OPEN IN TRAVEL INTERLOCKING SOLENOID

S/N A86001-A86216

S/N A86217-UP

E203 - SHORT IN SWING holding brake SOLENOID

S/N A86001-A86216

S/N A86217-UP

E204 - SHORT IN MERGE/DIVIDE SOLENOID

S/N A86001-A86216

S/N A86217-UP

E205 - SHORT IN 2 STAGE RELIEF SOLENOID

S/N A86001-A86216

S/N A86217-UP

E206 - SHORT IN TRAVEL SPEED SHIFT SOLENOID

S/N A86001-A86216

S/N A86217-UP

E211 - OPEN IN TRAVEL INTERLOCKING SOLENOID

S/N A86001-A86216

S/N A86217-UP

E213 - OPEN IN SWING holding BRAKE SOLENOID

S/N A86001-A86216

S/N A86217-UP

E214 - OPEN OF MERGE/DIVIDE SOLENOID

S/N A86001-A86216

S/N A86217-UP

E215 - OPEN IN 2 STAGE RELIEF SOLENOID

S/N A86001-A86216

S/N A86217-UP

E216 - OPEN IN TRAVEL SPEED SOLENOID

S/N A86001-A86216

S/N A86217-UP

E217 - ABNORMAL INPUT FOR MODEL CODE

E218 - OPEN IN S-NET SIGNAL

E222 - SHORT IN LS-EPC SOLENOID

E223 - OPEN IN LS-EPC SOLENOID SYSTEM

E224 - ABNORMAL F-PUMP PRESSURE SENSOR SIGNAL

E225 - ABNORMAL R-PUMP PRESSURE SENSOR SIGNAL

E226 - ABNORMAL PRESSURE SENSOR POWER SUPPLY

E227 - ABNORMAL ENGINE RPM SIGNAL IN GOVERNOR PUMP CONTROLLER

E228 - SHORT IN ATTACHMENT RETURN SWITCHING RELAY

E232 - SHORT IN PC-EPC SOLENOID

E233 - OPEN IN PC-EPC SOLENOID SYSTEM

E238 - OPEN IN ATTACHMENT RETURN SWITCH RELAY

E245 - SHORT IN ATTACHMENT OIL FLOW RATE EPC SYSTEM

E246 - OPEN IN ATTACHMENT OIL FLOW RATE EPC SYSTEM

E256 - INCORRECT NONVOLATILE MEMORY DATA

E306 - ABNORMAL GOVERNOR POTENTIOMETER SIGNALS

E308 - ABNORMAL FUEL DIAL SIGNALS

E315 - SHORT IN BATTERY RELAY SYSTEM

E316 - STEP OUT IN GOVERNOR MOTOR

E317 - OPEN IN GOVERNOR MOTOR PHASE "A" AND "B"

E318 - SHORT IN GOVERNOR MOTOR PHASE "A" AND "B"

E501 - MODEL SELECTION FUNCTION NOT PROVIDED

E502 - MODEL SELECTING SIGNAL FAULT

A000N1 - ENGINE SPEED OUT OF RANGE AT HIGH IDLE

A000N2 ENGINE SPEED OUT OF RANGE AT LOW IDLE

AA10NX - AIR CLEANER CLOGGING

AB00KE - LOW CHARGING VOLTAGE

S/N A86001-A86216

S/N A86217-UP

B@BAZG - ABNORMALLY LOWERED ENGINE OIL PRESSURE

B@BAZK - ABNORMALLY LOWERED ENGINE OIL LEVEL

B@BCNS - ENGINE COOLING WATER OVERHEATING

B@BCZK ABNORMALLY LOWERED RADIATOR WATER LEVEL

B@HANS - HYDRAULIC OIL OVERHEATING

ELECTRICAL SYSTEM (E-MODE)

Information Contained In Troubleshooting Table

Before Carrying Out Troubleshooting Of E Mode

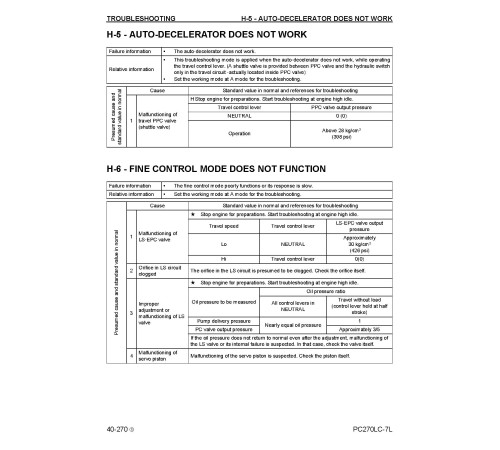

E-1 - ENGINE DOES NOT START (ENGINE DOES NO

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

PC270LC-7L (SN: A86001-)

Format: PDF, 838 pages

Language: English

Table of Contents:

SAFETY

Safety Notice

GENERAL

HOW TO READ THE SHOP MANUAL

Volumes

Distribution And Updating

Filing Method

Revised Edition Mark

Revisions

Symbols

HOISTING INSTRUCTIONS

Hoisting

Wire Ropes

PUSH-PULL TYPE COUPLER

COATING MATERIALS

STANDARD TIGHTENING TORQUE

Standard Tightening Torque Of Bolts And Nuts

Tightening Torque Of Split Flange Bolts

Tightening Torque For Flared Nuts

Table Of Tightening Torques For O-ring Boss Piping Joints

Table Of Tightening Torques For O-ring Boss Plugs

Tightening Torque For 102 And 114 Engine Series

Tightening Torque Table For Hoses (Taper Seal Type And Face Seal Type)

ELECTRIC WIRE CODE

Classification By Thickness

Classification By Color And Code

CONVERSION TABLES

Method Of Using The Conversion Table

SPECIFICATION DIMENSION DRAWINGS

Dimensions

Working Ranges

SPECIFICATIONS

WEIGHT TABLE

FUEL, COOLANT AND LUBRICANTS

Recommended Brands, Recommended Quality For Products Other Than Komatsu Genuine Oil

ENGINE RELATED PARTS

RADIATOR . OIL COOLER . AFTERCOOLER

POWER TRAIN

FINAL DRIVE

SWING MACHINERY

SWING CIRCLE

TRACK FRAME . RECOIL SPRING

IDLER

CARRIER ROLLER

TRACK ROLLER

TRACK SHOE

TRIPLE GROUSER SHOE

HYDRAULIC EQUIPMENT LAYOUT DRAWING

HYDRAULIC TANK

HYDRAULIC PUMP

HPV95+95

LS valve

PC Valve

LS(PC)-EPC Valve

CONTROL VALVE

SELF PRESSURE REDUCING VALVE

Main Relief Valve

VARIABLE PRESSURE COMPENSATION VALVE

CLSS

SWING MOTOR

Relief Valve Portion

REVERSE PREVENTION VALVE

CENTER SWIVEL JOINT

TRAVEL MOTOR

Motor Operation

Parking Brake Operation

Brake Valve Operation

TRAVEL JUNCTION VALVE

TRAVEL PPC SHUTTLE VALVE

VALVE CONTROL

WORK EQUIPMENT . SWING PPC VALVE

TRAVEL PPC VALVE

SERVICE PPC VALVE

SOLENOID VALVE

PPC ACCUMULATOR

RETURN OIL FILTER

BOOM HYDRAULIC DRIFT PREVENTION VALVE

LIFT CHECK VALVE

ATTACHMENT CIRCUIT SELECTOR VALVE

HYDRAULIC CYLINDERS

Boom Cylinder

Arm Cylinder

Bucket Cylinder

WORK EQUIPMENT

Hours

Hours

Dimension Of Arm

Dimension Of Bucket

AIR CONDITIONER

Piping

ENGINE CONTROL

Fuel Control Dial

Engine Throttle And Pump Controller

ELECTRONIC CONTROL SYSTEM

Total System Diagram

MULTI MONITOR SYSTEM

Monitor Panel

Monitor Control, Display Portion Monitor Portion

Maintenance Function

SEGMENT MONITOR SYSTEM

Monitor panel

SENSORS

Engine Oil Level Sensor

Engine Oil Pressure Sensor (For Low Pressure)

Coolant Temperature Sensor

Hydraulic Oil Temperature Sensor

Fuel Level Sensor

Air Cleaner Clogging Sensor

STANDARD VALUE TABLES

Engine

Chassis

SERVICE TOOLS

ENGINE

Engine Speed

Exhaust Gas Color

Valve Clearance

Compression Pressure

Blow-by Pressure

Fuel Injection Timing

Engine Oil Pressure

Engine Speed Sensor

Defective Cylinder

BELT TENSION - AIR COMPRESSOR

ENGINE CONTROL SYSTEM FAILURE

SWING CIRCLE BEARINGS

TRACK SHOE TENSION

SPROCKET

OIL PRESSURE

Work Equipment, Swing And Travel

Control Circuit

Pump PC Control Circuit

Pump LS Control Circuit

Solenoid Valve Output Pressure

PPC Valve Output Pressure

WORK EQUIPMENT AND SWING PPC VALVE

WORK EQUIPMENT - HYDRAULIC DRIFT

RELEASING PRESSURE IN HYDRAULIC CIRCUIT

OIL LEAKAGE

AIR BLEEDING OF VARIOUS PARTS

DIODE INSPECTION PROCEDURES

MULTI-MONITOR PANEL

Monitor Panel Functions - Conventional And Special

Conventional Function: Operator`s Menu

Special Function: Service Menu

Operator`s Menu And Display (Outline)

Table For Service And Failure Code Numbers

Service Menu

SEGMENTS MONITOR PANEL - SPECIAL FUNCTIONS

Ordinary functions and special functions of monitor panel

Display of operator menu

Operation and display of service menu

ELECTRICAL SYSTEM TROUBLESHOOTING

PM TUNE UP SERVICE

POINTS TO REMEMBER WHEN TROUBLESHOOTING

SEQUENCE OF EVENTS IN TROUBLESHOOTING

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

CHECKS BEFORE TROUBLESHOOTING

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

Classification Of Troubleshooting

Steps For Troubleshooting

Failure-looking Phenomenon And Troubleshooting No.

ELECTRICAL CIRCUIT DIAGRAM SYSTEM

Connector Table

Connector Location Diagram

ELECTRICAL CIRCUIT DIAGRAMS

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

T-BRANCH BOX AND T-BRANCH TABLE

BEFORE TROUBLESHOOTING FOR DISPLAYED CODE

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM

Points To Remember If Abnormality Returns To Normal By Itself

User Code Memory Retention Function

Information In Troubleshooting Table

E101 - ABNORMAL DATA IN ERROR HISTORY

E112 - SHORT IN WINDSHIELD WIPER MOTOR DRIVE FORWARD ROTATION

E113 - SHORT IN WINDSHIELD WIPER MOTOR DRIVE REVERSE ROTATION

E114 - SHORT OR OPEN IN WINDOW WASHER SYSTEM

S/N A86001-A86216

S/N A86217-UP

E115 - ABNORMAL WINDSHIELD WIPER MOTION

E116 - ABNORMALITY IN PARKING WIPER ARM

E201 - SHORT OR OPEN IN TRAVEL INTERLOCKING SOLENOID

S/N A86001-A86216

S/N A86217-UP

E203 - SHORT IN SWING holding brake SOLENOID

S/N A86001-A86216

S/N A86217-UP

E204 - SHORT IN MERGE/DIVIDE SOLENOID

S/N A86001-A86216

S/N A86217-UP

E205 - SHORT IN 2 STAGE RELIEF SOLENOID

S/N A86001-A86216

S/N A86217-UP

E206 - SHORT IN TRAVEL SPEED SHIFT SOLENOID

S/N A86001-A86216

S/N A86217-UP

E211 - OPEN IN TRAVEL INTERLOCKING SOLENOID

S/N A86001-A86216

S/N A86217-UP

E213 - OPEN IN SWING holding BRAKE SOLENOID

S/N A86001-A86216

S/N A86217-UP

E214 - OPEN OF MERGE/DIVIDE SOLENOID

S/N A86001-A86216

S/N A86217-UP

E215 - OPEN IN 2 STAGE RELIEF SOLENOID

S/N A86001-A86216

S/N A86217-UP

E216 - OPEN IN TRAVEL SPEED SOLENOID

S/N A86001-A86216

S/N A86217-UP

E217 - ABNORMAL INPUT FOR MODEL CODE

E218 - OPEN IN S-NET SIGNAL

E222 - SHORT IN LS-EPC SOLENOID

E223 - OPEN IN LS-EPC SOLENOID SYSTEM

E224 - ABNORMAL F-PUMP PRESSURE SENSOR SIGNAL

E225 - ABNORMAL R-PUMP PRESSURE SENSOR SIGNAL

E226 - ABNORMAL PRESSURE SENSOR POWER SUPPLY

E227 - ABNORMAL ENGINE RPM SIGNAL IN GOVERNOR PUMP CONTROLLER

E228 - SHORT IN ATTACHMENT RETURN SWITCHING RELAY

E232 - SHORT IN PC-EPC SOLENOID

E233 - OPEN IN PC-EPC SOLENOID SYSTEM

E238 - OPEN IN ATTACHMENT RETURN SWITCH RELAY

E245 - SHORT IN ATTACHMENT OIL FLOW RATE EPC SYSTEM

E246 - OPEN IN ATTACHMENT OIL FLOW RATE EPC SYSTEM

E256 - INCORRECT NONVOLATILE MEMORY DATA

E306 - ABNORMAL GOVERNOR POTENTIOMETER SIGNALS

E308 - ABNORMAL FUEL DIAL SIGNALS

E315 - SHORT IN BATTERY RELAY SYSTEM

E316 - STEP OUT IN GOVERNOR MOTOR

E317 - OPEN IN GOVERNOR MOTOR PHASE "A" AND "B"

E318 - SHORT IN GOVERNOR MOTOR PHASE "A" AND "B"

E501 - MODEL SELECTION FUNCTION NOT PROVIDED

E502 - MODEL SELECTING SIGNAL FAULT

A000N1 - ENGINE SPEED OUT OF RANGE AT HIGH IDLE

A000N2 ENGINE SPEED OUT OF RANGE AT LOW IDLE

AA10NX - AIR CLEANER CLOGGING

AB00KE - LOW CHARGING VOLTAGE

S/N A86001-A86216

S/N A86217-UP

B@BAZG - ABNORMALLY LOWERED ENGINE OIL PRESSURE

B@BAZK - ABNORMALLY LOWERED ENGINE OIL LEVEL

B@BCNS - ENGINE COOLING WATER OVERHEATING

B@BCZK ABNORMALLY LOWERED RADIATOR WATER LEVEL

B@HANS - HYDRAULIC OIL OVERHEATING

ELECTRICAL SYSTEM (E-MODE)

Information Contained In Troubleshooting Table

Before Carrying Out Troubleshooting Of E Mode

E-1 - ENGINE DOES NOT START (ENGINE DOES NO

General

Language

EnglishModel of Truck

PC270LC-7LRegion

USAType of Document

Workshop ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.