Model

CEBM007202SKU

40056Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA6D107E-1: SEN00161-24

$25.00

Language

EnglishModel of Truck

PC270LC-8Region

USAType of Document

Workshop ManualType of Truck

Crawler ExcavatorIllustrated factory Workshop Manual for Komatsu Crawler Excavators Models PC270LC-8.

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

PC270LC-8 (SN: A87001-)

Format: PDF, 1147 pages

Language: English

Table of Contents:

CEBM007202 - PC270LC-8 sn A87001 and up

REVISED PAGES

SAFETY

GENERAL

HOW TO READ THE SHOP MANUAL

HOISTING INSTRUCTIONS

PUSH PULL COUPLER

COATING MATERIALS

EXPLANATION OF MAINTENANCE STANDARD TERMS

STANDARD TIGHTENING TORQUE

ELECTRIC WIRE CODE

CONVERSION TABLES

GENERAL

SPECIFICATION AND TECHNICAL DATA

TABLE OF FUEL, COOLANT AND LUBRICANTS

STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD

ENGINE AND COOLING

POWER TRAIN

UNDERCARRIAGE AND FRAME

HYDRAULIC SYSTEM

WORK EQUIPMENT

CAB AND ITS ATTACHMENTS

ELECTRICAL SYSTEM

MONITOR SYSTEM

SENSORS

KOMTRAX TERMINAL SYSTEM

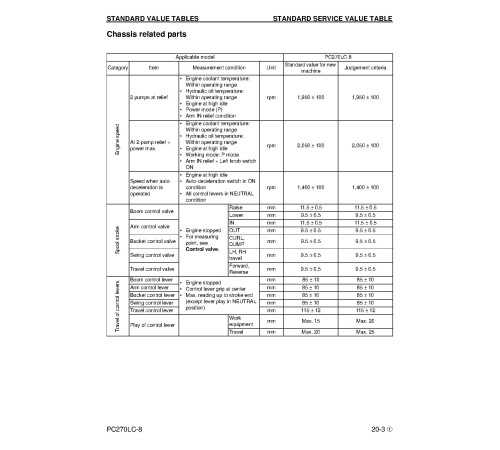

STANDARD VALUE TABLES

STANDARD SERVICE VALUE TABLE

TESTING AND ADJUSTING

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

ENGINE SPEED

INTAKE AIR PRESSURE (BOOST PRESSURE)

EXHAUST GAS COLOR

VALVE CLEARANCE

COMPRESSION PRESSURE

BLOW-BY PRESSURE

ENGINE OIL PRESSURE

HANDLING FUEL SYSTEM PARTS

AIR CONDITIONER COMPRESSOR BELT

FAN BELT

SWING CIRCLE BEARING

TRACK CHAIN TENSION

WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS OIL PRESSURE

CONTROL CIRCUIT BASIC PRESSURE

OIL PRESSURE IN PUMP PC CONTROL CIRCUIT

OIL PRESSURE IN PUMP LS CONTROL CIRCUIT

SOLENOID VALVE OUTPUT PRESSURE

PPC VALVE OUTPUT PRESSURE

WORK EQUIPMENT AND SWING PPC VALVES

HYDRAULIC DRIFT OF WORK EQUIPMENT

RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

OIL LEAKAGE

BLEEDING AIR FROM EACH PART

CAB TIPPING STOPPER

MIRRORS

SPECIAL FUNCTIONS OF MACHINE MONITOR

HANDLING VOLTAGE CIRCUIT OF ENGINE CONTROLLER

PREPARATION WORK FOR ELECTRICAL SYSTEM

PROCEDURE FOR TESTING DIODES

PM CLINIC SERVICE

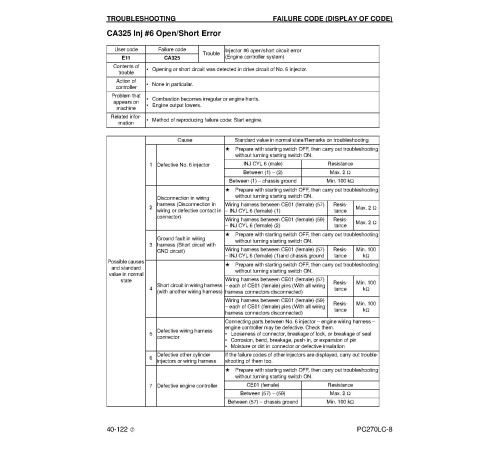

TROUBLESHOOTING

GENERAL INFORMATION

FAILURE CODE (DISPLAY OF CODE)

ELECTRICAL SYSTEM (E-MODE)

HYDRAULIC AND MECHANICAL SYSTEM (H-MODE)

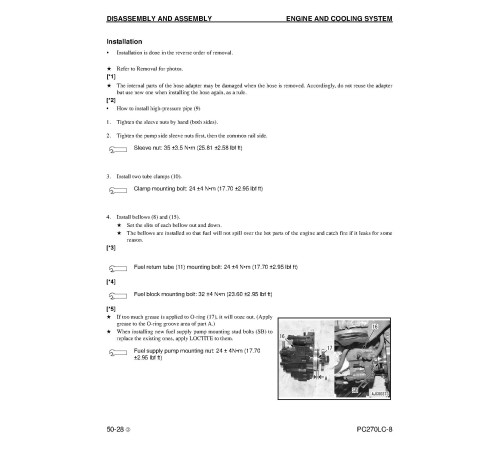

DISASSEMBLY AND ASSEMBLY

HOW TO READ THIS SECTION

SPECIAL TOOLS LIST

SKETCHES OF SPECIAL TOOLS

CONNECTOR REPAIR PROCEDURES

ENGINE AND COOLING SYSTEM

POWER TRAIN

UNDERCARRIAGE AND FRAME

HYDRAULIC SYSTEM

WORK EQUIPMENT

CAB AND ITS ATTACHMENTS

ELECTRICAL SYSTEM

AIR CONDITIONER

STRUCTURE AND FUNCTION

TESTING AND ADJUSTING

TROUBLESHOOTING

DIAGRAMS AND SCHEMATICS

HYDRAULIC SYSTEM

ELECTRICAL SYSTEM

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

PC270LC-8 (SN: A87001-)

Format: PDF, 1147 pages

Language: English

Table of Contents:

CEBM007202 - PC270LC-8 sn A87001 and up

REVISED PAGES

SAFETY

GENERAL

HOW TO READ THE SHOP MANUAL

HOISTING INSTRUCTIONS

PUSH PULL COUPLER

COATING MATERIALS

EXPLANATION OF MAINTENANCE STANDARD TERMS

STANDARD TIGHTENING TORQUE

ELECTRIC WIRE CODE

CONVERSION TABLES

GENERAL

SPECIFICATION AND TECHNICAL DATA

TABLE OF FUEL, COOLANT AND LUBRICANTS

STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD

ENGINE AND COOLING

POWER TRAIN

UNDERCARRIAGE AND FRAME

HYDRAULIC SYSTEM

WORK EQUIPMENT

CAB AND ITS ATTACHMENTS

ELECTRICAL SYSTEM

MONITOR SYSTEM

SENSORS

KOMTRAX TERMINAL SYSTEM

STANDARD VALUE TABLES

STANDARD SERVICE VALUE TABLE

TESTING AND ADJUSTING

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

ENGINE SPEED

INTAKE AIR PRESSURE (BOOST PRESSURE)

EXHAUST GAS COLOR

VALVE CLEARANCE

COMPRESSION PRESSURE

BLOW-BY PRESSURE

ENGINE OIL PRESSURE

HANDLING FUEL SYSTEM PARTS

AIR CONDITIONER COMPRESSOR BELT

FAN BELT

SWING CIRCLE BEARING

TRACK CHAIN TENSION

WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS OIL PRESSURE

CONTROL CIRCUIT BASIC PRESSURE

OIL PRESSURE IN PUMP PC CONTROL CIRCUIT

OIL PRESSURE IN PUMP LS CONTROL CIRCUIT

SOLENOID VALVE OUTPUT PRESSURE

PPC VALVE OUTPUT PRESSURE

WORK EQUIPMENT AND SWING PPC VALVES

HYDRAULIC DRIFT OF WORK EQUIPMENT

RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

OIL LEAKAGE

BLEEDING AIR FROM EACH PART

CAB TIPPING STOPPER

MIRRORS

SPECIAL FUNCTIONS OF MACHINE MONITOR

HANDLING VOLTAGE CIRCUIT OF ENGINE CONTROLLER

PREPARATION WORK FOR ELECTRICAL SYSTEM

PROCEDURE FOR TESTING DIODES

PM CLINIC SERVICE

TROUBLESHOOTING

GENERAL INFORMATION

FAILURE CODE (DISPLAY OF CODE)

ELECTRICAL SYSTEM (E-MODE)

HYDRAULIC AND MECHANICAL SYSTEM (H-MODE)

DISASSEMBLY AND ASSEMBLY

HOW TO READ THIS SECTION

SPECIAL TOOLS LIST

SKETCHES OF SPECIAL TOOLS

CONNECTOR REPAIR PROCEDURES

ENGINE AND COOLING SYSTEM

POWER TRAIN

UNDERCARRIAGE AND FRAME

HYDRAULIC SYSTEM

WORK EQUIPMENT

CAB AND ITS ATTACHMENTS

ELECTRICAL SYSTEM

AIR CONDITIONER

STRUCTURE AND FUNCTION

TESTING AND ADJUSTING

TROUBLESHOOTING

DIAGRAMS AND SCHEMATICS

HYDRAULIC SYSTEM

ELECTRICAL SYSTEM

General

Language

EnglishModel of Truck

PC270LC-8Region

USAType of Document

Workshop ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.