Model

EEAM010300SKU

40079Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: 6D107E-2: SEN05623-06

$15.00

Language

EnglishModel of Truck

PC290LC-6K, PC290NLC-6KRegion

United KingdomType of Document

Operate and Maintenance manualType of Truck

Crawler ExcavatorIllustrated factory Operate and Maintenance manual for Komatsu Crawler Excavators Models PC290LC-6K and PC290NLC-6K.

This manual will assist you in operating, and maintaining for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (United Kingdom):

PC290LC-6K (SN: K30001-34000)

PC290NLC-6K (SN: K30001-34000)

Format: PDF, 264 pages

Language: English

Table of Contents:

FOREWORD

SAFETY INFORMATION

INTRODUCTION

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

SAFETY

GENERAL PRECAUTIONS

PRECAUTIONS DURING OPERATION

Before starting engine

Operating machine

Transportation

Battery

Towing

Bucket with hook

PRECAUTIONS FOR MAINTENANCE

Before carrying out maintenance

During maintenance

POSITION FOR ATTACHING SAFETY LABELS

OPERATION

GENERAL VIEW

General view of machine

General view of controls and gauges

EXPLANATION OF COMPONENTS

Machine monitor

Meter

switches

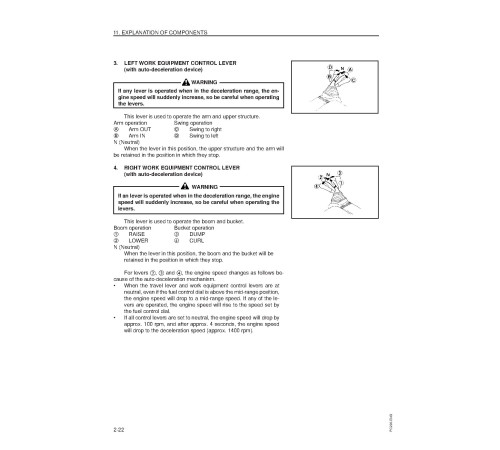

Control levers, pedals

Ceiling window

Front window

Door lock

Cap, cover with lock

Luggage tray

Ashtray

Heater

Air conditioner

Car radio

Fuse

Fusible link

Controllers

Tool box

Refuelling pump

Handling the accumulator

OPERATION

Check before starting engine

Starting engine

Operations and checks after starting engine

Moving machine off

Steering machine

Stopping machine

Swinging

Operation of work equipment

Handling active mode

Working mode selection

Prohibitions for operation

Precaution for operation

Precaution when travelling up or down hills

How to escape from mud

Work possible using hydraulic excavator

Replacement and inversion of bucket

Parking the machine

Check after finishing work

Stopping engine

Check after stopping engine

Locking

Overload warning device

TRANSPORTATION

Loading, unloading work

Precautions for loading

Precautions for transportation

Lifting the machine

COLD WEATHER OPERATION

Precaution for low temperature

Precautions after completion of work

After cold weather

LONG-TERM STORAGE

Before storage

Posture when leaving machine

During storage

After storage

Starting machine after long-term storage

TROUBLESHOOTING

Phenomena that are not failures

Method of towing machine

Using method for light-weight towing hole

Precautions on particular jobsites

If battery is discharged

Other trouble

MAINTENANCE

GUIDES TO MAINTENANCE

OUTLINES OF SERVICE

Outline of oil, fuel, coolant

Outline of electric system

Outline of hydraulic system

WEAR PARTS LIST

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

PRECAUTIONS WHEN HANDLING

TESTING AND ADJUSTING

PERIODIC MAINTENANCE

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

Introduction of necessary tools

Torque list

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

MAINTENANCE SCHEDULE CHART

Maintenance schedule chart

Maintenance interval when using hydraulic breaker

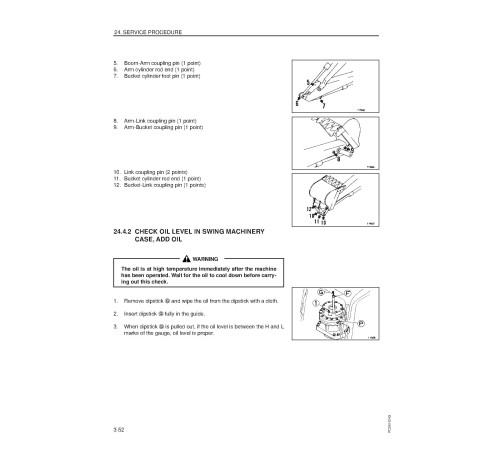

SERVICE PROCEDURE

Initial 250 hours service

When required

Check before staring

Every 100 hours service

Every 250 hours service

Every 500 hours service

Every 1000 hours service

Every 2000 hours service

Every 4000 hours service

Every 5000 hours service

SPECIFICATIONS

MACHINE SPECIFICATIONS

Machine specifications

Explanation of lifting capacity chart

TRANSPORTATION

COMPONENTS DIMENSIONS AND WEIGHTS (Approximate) • (Two Piece Boom)

OPTIONS AND ATTACHMENTS

GENERAL PRECAUTIONS

General precautions related to safety

Precautions when installing attachments

HANDLING BUCKET WITH HOOK

Checking for damage to bucket with hook

Prohibited operations

Precautions during operation

MACHINE READY FOR ATTACHMENTS

Explanation of components

Hydraulic circuit

Attachment mounting / dismounting procedure

Operation

Long-term storage

Specifications

First attachment with clam-shell option

First and second attachment

INTRODUCTION OF ATTACHMENTS

Specification, use

Attachment installing combination table

Selection of track shoes

Selection of bucket teeth

Handling trapezoidal bucket

Using the extension arm

Handling the clamshell bucket

EXTENDING MACHINE SERVICE LIFT

Hydraulic breaker

Power ripper

Fork grab

Grapple bucket

Scrap grapple

Crusher & cutter

Hydraulic pile driver

Hydraulic excavator with multi-purpose crane .

This manual will assist you in operating, and maintaining for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (United Kingdom):

PC290LC-6K (SN: K30001-34000)

PC290NLC-6K (SN: K30001-34000)

Format: PDF, 264 pages

Language: English

Table of Contents:

FOREWORD

SAFETY INFORMATION

INTRODUCTION

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

SAFETY

GENERAL PRECAUTIONS

PRECAUTIONS DURING OPERATION

Before starting engine

Operating machine

Transportation

Battery

Towing

Bucket with hook

PRECAUTIONS FOR MAINTENANCE

Before carrying out maintenance

During maintenance

POSITION FOR ATTACHING SAFETY LABELS

OPERATION

GENERAL VIEW

General view of machine

General view of controls and gauges

EXPLANATION OF COMPONENTS

Machine monitor

Meter

switches

Control levers, pedals

Ceiling window

Front window

Door lock

Cap, cover with lock

Luggage tray

Ashtray

Heater

Air conditioner

Car radio

Fuse

Fusible link

Controllers

Tool box

Refuelling pump

Handling the accumulator

OPERATION

Check before starting engine

Starting engine

Operations and checks after starting engine

Moving machine off

Steering machine

Stopping machine

Swinging

Operation of work equipment

Handling active mode

Working mode selection

Prohibitions for operation

Precaution for operation

Precaution when travelling up or down hills

How to escape from mud

Work possible using hydraulic excavator

Replacement and inversion of bucket

Parking the machine

Check after finishing work

Stopping engine

Check after stopping engine

Locking

Overload warning device

TRANSPORTATION

Loading, unloading work

Precautions for loading

Precautions for transportation

Lifting the machine

COLD WEATHER OPERATION

Precaution for low temperature

Precautions after completion of work

After cold weather

LONG-TERM STORAGE

Before storage

Posture when leaving machine

During storage

After storage

Starting machine after long-term storage

TROUBLESHOOTING

Phenomena that are not failures

Method of towing machine

Using method for light-weight towing hole

Precautions on particular jobsites

If battery is discharged

Other trouble

MAINTENANCE

GUIDES TO MAINTENANCE

OUTLINES OF SERVICE

Outline of oil, fuel, coolant

Outline of electric system

Outline of hydraulic system

WEAR PARTS LIST

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

PRECAUTIONS WHEN HANDLING

TESTING AND ADJUSTING

PERIODIC MAINTENANCE

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

Introduction of necessary tools

Torque list

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

MAINTENANCE SCHEDULE CHART

Maintenance schedule chart

Maintenance interval when using hydraulic breaker

SERVICE PROCEDURE

Initial 250 hours service

When required

Check before staring

Every 100 hours service

Every 250 hours service

Every 500 hours service

Every 1000 hours service

Every 2000 hours service

Every 4000 hours service

Every 5000 hours service

SPECIFICATIONS

MACHINE SPECIFICATIONS

Machine specifications

Explanation of lifting capacity chart

TRANSPORTATION

COMPONENTS DIMENSIONS AND WEIGHTS (Approximate) • (Two Piece Boom)

OPTIONS AND ATTACHMENTS

GENERAL PRECAUTIONS

General precautions related to safety

Precautions when installing attachments

HANDLING BUCKET WITH HOOK

Checking for damage to bucket with hook

Prohibited operations

Precautions during operation

MACHINE READY FOR ATTACHMENTS

Explanation of components

Hydraulic circuit

Attachment mounting / dismounting procedure

Operation

Long-term storage

Specifications

First attachment with clam-shell option

First and second attachment

INTRODUCTION OF ATTACHMENTS

Specification, use

Attachment installing combination table

Selection of track shoes

Selection of bucket teeth

Handling trapezoidal bucket

Using the extension arm

Handling the clamshell bucket

EXTENDING MACHINE SERVICE LIFT

Hydraulic breaker

Power ripper

Fork grab

Grapple bucket

Scrap grapple

Crusher & cutter

Hydraulic pile driver

Hydraulic excavator with multi-purpose crane .

General

Language

EnglishModel of Truck

PC290LC-6K, PC290NLC-6KRegion

United KingdomType of Document

Operate and Maintenance manualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.