Model

SEAWD01803SKU

40146Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA6D107E-1: SEN00161-24

$10.00

Language

EnglishModel of Truck

PC750-6, PC750LC-6, PC750SE-6, PC800SE-6, PC800-6Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler ExcavatorIllustrated factory Field Assembly Manual for Komatsu Crawler Excavators Models PC750-6, PC750LC-6, PC750SE-6, PC800-6 and PC800SE-6.

This manual will assist you in for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

PC750-6 (SN: 11001-)

PC750LC-6 (SN: 11001-)

PC750SE-6 (SN: 11001-)

PC800-6 (SN: 31001-)

PC800SE-6 (SN: 31001-)

Format: PDF, 165 pages

Language: English

Table of Contents:

SPECIFICATIONS

FIELD ASSEMBLING

ASSEMBLING PROCEDURES, APPLICABLE EQUIPMENT AND SCHEDULE

TRANSPORTATION

PACKING STYLE FOR TRANSPORTATION

LIST OF TOOLS FOR FIELD ASSEMBLING

STANDARD TIGHTENING TORQUE

A. ASSEMBLY OF BASE MACHINE

A-1 FITTING OF LEFT AND RIGHT TRACK FRAMES

A-2 ARRANGEMENT OF TRAVEL PIPE

A-3 INSTALLATION OF FOG

A-4 INSTALLATION OF RADIATOR COVER

A-5 INSTALLATION OF REAR VIEW MIRROR

A-6 INSTALLATION OF HANDRAIL

A-7 INSTALLATION OF STEP

A-8 INSTALLATION OF LEFT SIDE STEP

A-9 SETTING OF MUFFLER TAIL TUBE

A-10 STICKING SHEET (TO COUNTERWEIGHT)

A-11 INSTALLATION OF COUNTERWEIGHT

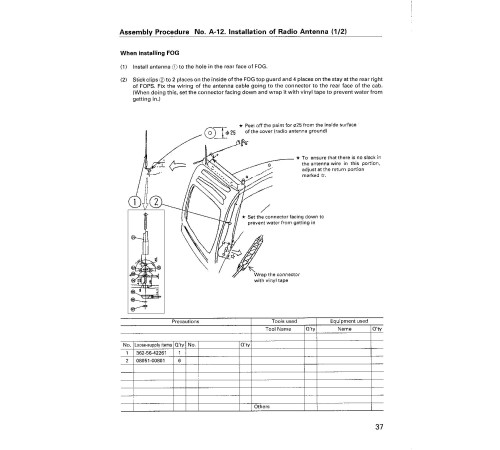

A-12 INSTALLATION OF RADIO ANTENNA

A-13 INSTALLATION OF CAB TOP LIGHT

A-14 SETTING OF TRAVEL PIPE COVER

A-15 ADJUSTMENT OF TRACK TENSION

A-15A EXTENSION OF TRACK FRAME GAUGE (ONLY WHEN 3-SPLIT PACKAGES ARE TRANSPORTED)

A-16 INSPECTION OF OIL AMOUNT AND WATER AMOUNT

B. ASSEMBLING OF WORK EQUIPMENT

B-1 BOOM FOOT PIN, AND BOOM CYLINDER FOOT PIN

B-2 BOOM ASSEMBLY

B-3 RELIEVING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT

B-4 INSTALLATION OF BOOM CYLINDER FOOT

B-5 ARRANGEMENT OF BOOM CYLINDER HOSE

B-6 INSTALLATION OF BOOM CYLINDER

B-7 INSTALLATION OF ARM CYLINDER

B-8 ARRANGEMENT OF ARM CYLINDER HOSE

B-9 INSTALLATION OF ARM ASSEMBLY

B-10 ARRANGEMENT OF HOSE BETWEEN BOOM AND BUCKET CYLINDER

B-11 INSTALLATION OF BUCKET ASSEMBLY

B-12 LUBRICATION PIPING TO WORK EQUIPMENT

B-13 AIR BLEEDING FROM CYLINDER

B-14 WIRING OF WORK EQUIPMENT

B-15 GREASING OF ASSEMBLED WORK EQUIPMENT

M. PROCEDURE FOR INSPECTION AND MAINTENANCE AFTER COMPLETION OF ASSEMBLY

M-1 INSPECTION OF OIL LEVEL IN HYDRAULIC TANK AND REFILL

M-2 REPLACEMENT OF RETURN FILTER (STANDARD FILTER TO FLUSHING FILTER)

M-3 FLUSHING OF HYDRAULIC CIRCUIT

C. ASSEMBLING OF WORK EQUIPMENT OF LOADING SHOVEL

C-1 RELEASEING RESIDUAL PRESSURE IN HYDRAULIC CIRCUIT

C-2 PULLING OUT BOOM FOOT PIN AND BOOM CYLINDER FOOT PIN

C-3 INSTALLATION OF BOOM AND ARM ASSEMBLY

C-4 INSTALLATION OF FLUSHING PIPING BETWEEN CHASSIS AND BOOM

C-5 INSTALLATION OF FLUSHING PIPING FOR BOOM CYLINDER AND ARM CYLINDER

C-6 INSTALLATION OF FLUSHING PIPING FOR BUCKET CYLINDER

C-7 INSTALLATION OF FLUSHING PIPING FOR BOTTOM DUMP CYLINDER

C-8 INSTALLATION OF BOOM CYLINDER

C-9 ISTALLATION OF BOOM CYLINDER FOOT

C-10 INSTALLATION OF BOOM CYLINDER HOSES

C-11 INSTALLATION OF BOOM CYLINDER ROD PIN

C-12 INSTALLATION OF ARM CYLINDER HOSES

C-13 INSTALLATION OF BUCKET CYLINDER

C-14 INSTALLATION OF BUCKET CYLINDER HOSE

C-15 INSTALLATION OF CONNECTING HOSES BETWEEN CHASSIS AND BOOM TOP

C-16 INSTALLATION OF BOTTOM DUMP CYLINDER HOSES

C-17 INSTALLATION OF BUCKET ASSEMBLY

C-18 INSTALLATION OF WORKING LAMPS

C-19 INSTALLATION OF WORK EQUIPMENT FREASE PIPING

C-20 GREASING AFTER ASSEMBLING OF WORK EQUIPMENT

C-21 BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT

C-22 FLUSHING OF WORK EQUIPMENT PIPING

C-23 CHECKING OIL LEVEL IN HYDRAULIC TANK AND ADDING OIL

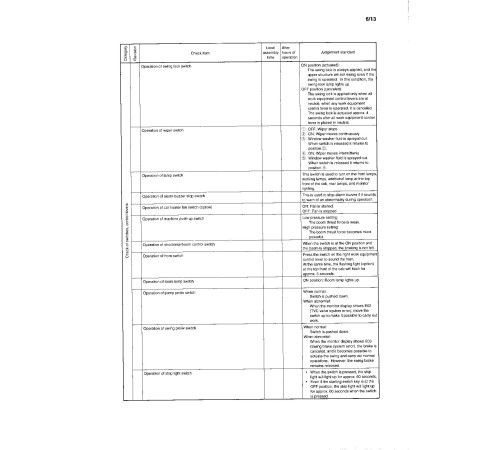

FIELD ASSEMBLY INSPECTION REPORT

This manual will assist you in for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

PC750-6 (SN: 11001-)

PC750LC-6 (SN: 11001-)

PC750SE-6 (SN: 11001-)

PC800-6 (SN: 31001-)

PC800SE-6 (SN: 31001-)

Format: PDF, 165 pages

Language: English

Table of Contents:

SPECIFICATIONS

FIELD ASSEMBLING

ASSEMBLING PROCEDURES, APPLICABLE EQUIPMENT AND SCHEDULE

TRANSPORTATION

PACKING STYLE FOR TRANSPORTATION

LIST OF TOOLS FOR FIELD ASSEMBLING

STANDARD TIGHTENING TORQUE

A. ASSEMBLY OF BASE MACHINE

A-1 FITTING OF LEFT AND RIGHT TRACK FRAMES

A-2 ARRANGEMENT OF TRAVEL PIPE

A-3 INSTALLATION OF FOG

A-4 INSTALLATION OF RADIATOR COVER

A-5 INSTALLATION OF REAR VIEW MIRROR

A-6 INSTALLATION OF HANDRAIL

A-7 INSTALLATION OF STEP

A-8 INSTALLATION OF LEFT SIDE STEP

A-9 SETTING OF MUFFLER TAIL TUBE

A-10 STICKING SHEET (TO COUNTERWEIGHT)

A-11 INSTALLATION OF COUNTERWEIGHT

A-12 INSTALLATION OF RADIO ANTENNA

A-13 INSTALLATION OF CAB TOP LIGHT

A-14 SETTING OF TRAVEL PIPE COVER

A-15 ADJUSTMENT OF TRACK TENSION

A-15A EXTENSION OF TRACK FRAME GAUGE (ONLY WHEN 3-SPLIT PACKAGES ARE TRANSPORTED)

A-16 INSPECTION OF OIL AMOUNT AND WATER AMOUNT

B. ASSEMBLING OF WORK EQUIPMENT

B-1 BOOM FOOT PIN, AND BOOM CYLINDER FOOT PIN

B-2 BOOM ASSEMBLY

B-3 RELIEVING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT

B-4 INSTALLATION OF BOOM CYLINDER FOOT

B-5 ARRANGEMENT OF BOOM CYLINDER HOSE

B-6 INSTALLATION OF BOOM CYLINDER

B-7 INSTALLATION OF ARM CYLINDER

B-8 ARRANGEMENT OF ARM CYLINDER HOSE

B-9 INSTALLATION OF ARM ASSEMBLY

B-10 ARRANGEMENT OF HOSE BETWEEN BOOM AND BUCKET CYLINDER

B-11 INSTALLATION OF BUCKET ASSEMBLY

B-12 LUBRICATION PIPING TO WORK EQUIPMENT

B-13 AIR BLEEDING FROM CYLINDER

B-14 WIRING OF WORK EQUIPMENT

B-15 GREASING OF ASSEMBLED WORK EQUIPMENT

M. PROCEDURE FOR INSPECTION AND MAINTENANCE AFTER COMPLETION OF ASSEMBLY

M-1 INSPECTION OF OIL LEVEL IN HYDRAULIC TANK AND REFILL

M-2 REPLACEMENT OF RETURN FILTER (STANDARD FILTER TO FLUSHING FILTER)

M-3 FLUSHING OF HYDRAULIC CIRCUIT

C. ASSEMBLING OF WORK EQUIPMENT OF LOADING SHOVEL

C-1 RELEASEING RESIDUAL PRESSURE IN HYDRAULIC CIRCUIT

C-2 PULLING OUT BOOM FOOT PIN AND BOOM CYLINDER FOOT PIN

C-3 INSTALLATION OF BOOM AND ARM ASSEMBLY

C-4 INSTALLATION OF FLUSHING PIPING BETWEEN CHASSIS AND BOOM

C-5 INSTALLATION OF FLUSHING PIPING FOR BOOM CYLINDER AND ARM CYLINDER

C-6 INSTALLATION OF FLUSHING PIPING FOR BUCKET CYLINDER

C-7 INSTALLATION OF FLUSHING PIPING FOR BOTTOM DUMP CYLINDER

C-8 INSTALLATION OF BOOM CYLINDER

C-9 ISTALLATION OF BOOM CYLINDER FOOT

C-10 INSTALLATION OF BOOM CYLINDER HOSES

C-11 INSTALLATION OF BOOM CYLINDER ROD PIN

C-12 INSTALLATION OF ARM CYLINDER HOSES

C-13 INSTALLATION OF BUCKET CYLINDER

C-14 INSTALLATION OF BUCKET CYLINDER HOSE

C-15 INSTALLATION OF CONNECTING HOSES BETWEEN CHASSIS AND BOOM TOP

C-16 INSTALLATION OF BOTTOM DUMP CYLINDER HOSES

C-17 INSTALLATION OF BUCKET ASSEMBLY

C-18 INSTALLATION OF WORKING LAMPS

C-19 INSTALLATION OF WORK EQUIPMENT FREASE PIPING

C-20 GREASING AFTER ASSEMBLING OF WORK EQUIPMENT

C-21 BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT

C-22 FLUSHING OF WORK EQUIPMENT PIPING

C-23 CHECKING OIL LEVEL IN HYDRAULIC TANK AND ADDING OIL

FIELD ASSEMBLY INSPECTION REPORT

General

Language

EnglishModel of Truck

PC750-6, PC750LC-6, PC750SE-6, PC800SE-6, PC800-6Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.