Model

SEAWD021N0103SKU

40510Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA6D107E-1: SEN00161-24

$10.00

Language

EnglishModel of Truck

PC1000-1, PC1000LC-1, PC1000SE-1Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler ExcavatorIllustrated factory Field Assembly Manual for Komatsu Crawler Excavators Models PC1000-1, PC1000LC-1 and PC1000SE-1.

This manual will assist you in for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

PC1000-1 (SN: 10001-)

PC1000LC-1 (SN: 10001-)

PC1000SE-1 (SN: 10001-)

Format: PDF, 180 pages

Language: English

Table of Contents:

A. GENERAL

A-1: BEFORE ASSEMBLY

A-2: LIST OF PARTS SENT INDIVIDUALLY

A-3: POINTS REGARDING LOCAL ASSEMBLY

A-4: PRECAUTIONS WHEN ASSEMBLING, TIGHTENING TORQUE OF BOLTS, SCREWS AND TAPER SEAL HOSES

A-5: TABLE OF TOOLS FOR LOCAL ASSEMBLY

A-6: PLACE TO SET (UNLOAD) EACH UNIT

B. ASSEMBLY OF MACHINE (PART I)

B-1: INSTALLATION OF LEFT, RIGHT TRACK FRAMES

B-2: INSTALLATION OF TRAVEL PIPING

B-3: EXCHAING RETURN FILTER (STANDARD PART - SPECIAL FLUSHING PART)

B-4: CHECK OF OIL AND WATER LEVELS

B-5: CHECK CENTRAL MONITOR

B-6: BLEEDING AIR FROM HYDRAULIC PUMP, SWING PUMP

B-7: FLUSHING TRAVEL CIRCUIT

B-8: INSTALLATION OF TRAVEL PIPING

C. ASSEMBLY OF MACHINE (PART II)

C-1: INSTALLATION OF LEFT SIDE STEP

C-2: INSTALLATION OF STEP

C-3: INSTALLATION OF HANDRAIL

C-4: INSTALLATION OF STEP (ONLY WHEN INSTALLING HIGH CAB)

C-5: INSTALLATION OF OPERATOR'S CAB ASSEMBLY

C-6: CONNECTION OF ELECTRICAL COMPONENTS IN OPERATOR'S CAB (ONLY WHEN INSTALLING HIGH CAB)

C-7: INSTALLATION OF AIR CONDITIONER (ONLY WHEN INSTALLING HIGH CAB)

C-8: INSTALLATION OF OPERATOR'S SEAT ASSEMBLY (ONLY WHEN INSTALLING HIGH CAB)

C-9: INSTALLATION OF ADDITIONAL REAR VIEW MIRROR (OPTION)

C-10: INSTALLATION OF FOPS (OPTION)

C-11: INSTALLATION OF MUFFLER TAIL PIPE

C-12: INSTALLATION OF COUNTERWEIGHT ASSEMBLY

C-13: EXCHANGING RETURN FILTER (STANDARD PART - SPECIAL FLUSHING PART)

C-14: CHECK OF OIL AND WATER LEVELS

C-15: CHECK CENTRAL MONITOR (CARRY OUT ONLY WHEN MACHINE IS DIVIDED INTO THREE PARTS FOR TRANSPORTATION)

C-16: BLEEDING AIR FROM TRAVEL MOTOR CIRCUIT

C-17: BLEEDING AIR FROM HYDRAULIC IDLER CUSHION CIRCUIT

C-18: ADJUSTMENT OF HYDRAULIC IDLER CUSHION CYLINDER

C-19: ADJUSTING TRACK TENSION

D. PROCEDURE FOR ASSEMBLY OF WORK EQUIPMENT (BACKHOE SPECIFICATION)

D-1: ASSEMBLY OF BOOM ASSEMBLY

D-2: RELEASING PRESSURE FROM HYDRAULIC CIRCUIT

D-3: WORK EQUIPMENT PIPING (BETWEEN CHASSIS AND BOOM) (BETWEEN CHASSIS AND BOOM CYLINDER)

D-4: FLUSHING WORK EQUIPMENT PIPING

D-5: INSTALLATION OF BOOM CYLINDER FOOT PIN

D-6: INSTALLING BOOM CYLINDER HOSES

D-7: INSTALLATION OF BOOM CYLINDER TOP PIN

D-8: INSTALLATION OF ARM CYLINDER FOOT PIN

D-9: WORK EQUIPMENT PIPING (ARM CYLINDER)

D-10: INSTALLATION OF ARM AND ARM CYLINDER TOP PIN

D-11: WORK EQUIPMENT PIPING (BOOM-BUCKET CYLINDER)

D-12: ASSEMBLY OF BUCKET ASSEMBLY

D-13: MAINTENANCE STANDARD

D-14: INSTALLATION OF WORK EQUIPMENT GREASE PIPING

D-15: INSTALLATION OF WORK EQUIPMENT WIRING AND WORK EQUIPMENT HOSE CLAMPS

D-16: BLEEDING AIR FROM CYLINDER

D-17: CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

E. PROCEDURE FOR ASSEMBLY OF WORK EQUIPMENT (FRONT LOADING SHOVEL SPECIFICATION)

E-1: INSTALLATION OF ARM CYLINDER FOOT PIN

E-2: CONNECTION OF BOOM AND ARM

E-3: INSTALLATION OF ARM CYLINDER TOP PIN

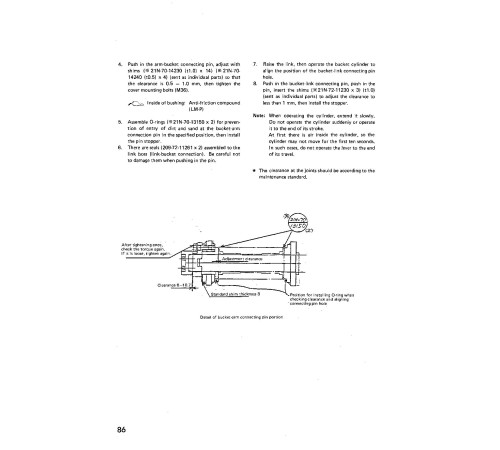

E-4: INSTALLATION OF BUCKET CYLINDER FOOT PIN

E-5: CONNECTION OF LINK AND BUCKET CYLINDER TOP PIN

E-6: ASSEMBLY OF BOOM ASSEMBLY

E-7: RELEASING PRESSURE FROM HYDRAULIC CIRCUIT

E-8: WORK EQUIPMENT PIPING (BETWEEN CHASSIS AND BOOM)

E-9: WORK EQUIPMENT PIPING

E-10: FLUSHING WORK EQUIPMENT PIPING

E-11: INSTALLATION OF BOOM CYLINDER FOOT PIN

E-12: INSTALLATION OF BOOM CYLINDER HOSES

E-13: INSTALLATION OF BOOM CYLINDER TOP PIN

E-14: INSTALLATION OF ARM CYLINDER HOSES

E-15: INSTALLATION OF BUCKET CYLINDER PIPING

E-16: INSTALLATION OF BOTTOM DUMP CYLINDER PIPING

E-17: INSTALLATION OF BUCKET ASSEMBLY

E-18: MAINTENANCE STANDARD

E-19: INSTALLATION OF BOTTOM DUMP CYLINDER PIPING

E-20: INSTALLATION OF WORK EQUIPMENT PIPING CLAMPS

E-21: INSTALLATION OF WORKING LAMP

E:22: INSTALLATION OF WORK EQUIPMENT GREASE PIPING

E-23: BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT

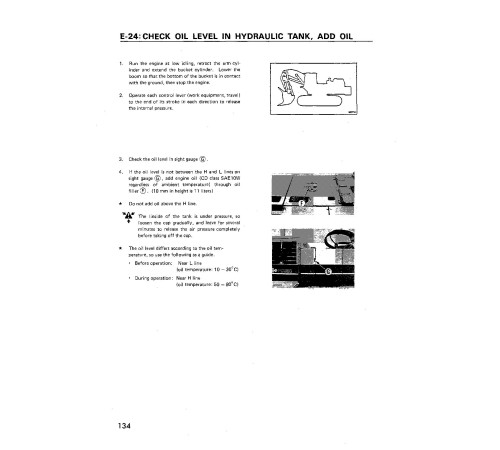

E-24: CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

E-25: INSTALLATION OF BOOM FOOT POTENTIOMETER

E-26: INSTALLATION AND ADJUSTMENT OF BOOM TOP POTENTIOMETER (BOOM - ARM JOINT)

E-27: INSTALLATION OF CLAMPS AND COVER FOR BOOM FOOT POTENTIOMETER

E-28: INSTALLATION OF CLAMPS AND COVER FOR BOOM TOP POTENTIOMETER

E-29: ADJUSTMENT OF WORK EQUIPMENT CONTROLLER (FOR AUTOMATIC CONTROL OF LOADING SHOVEL)

F. ASSEMBLY OF MACHINE (PART III)

F-1: EXTENDING TRACK FRAME GAUGE WIDTH (ONLY WHEN DIVIDED INTO THREE PARTS FOR TRANSPORTATION)

F-2: INSTALLATION OF TRAVEL PIPING COVERS

G. CHECK OF ALL PARTS DURING AND AFTER ASSEMBLY

H. PCIOOO-1 55°C AUSTRALIA SPECIFICATION

APPENDIX

FIELD ASSEMBLY INSPECTION REPORT

This manual will assist you in for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

PC1000-1 (SN: 10001-)

PC1000LC-1 (SN: 10001-)

PC1000SE-1 (SN: 10001-)

Format: PDF, 180 pages

Language: English

Table of Contents:

A. GENERAL

A-1: BEFORE ASSEMBLY

A-2: LIST OF PARTS SENT INDIVIDUALLY

A-3: POINTS REGARDING LOCAL ASSEMBLY

A-4: PRECAUTIONS WHEN ASSEMBLING, TIGHTENING TORQUE OF BOLTS, SCREWS AND TAPER SEAL HOSES

A-5: TABLE OF TOOLS FOR LOCAL ASSEMBLY

A-6: PLACE TO SET (UNLOAD) EACH UNIT

B. ASSEMBLY OF MACHINE (PART I)

B-1: INSTALLATION OF LEFT, RIGHT TRACK FRAMES

B-2: INSTALLATION OF TRAVEL PIPING

B-3: EXCHAING RETURN FILTER (STANDARD PART - SPECIAL FLUSHING PART)

B-4: CHECK OF OIL AND WATER LEVELS

B-5: CHECK CENTRAL MONITOR

B-6: BLEEDING AIR FROM HYDRAULIC PUMP, SWING PUMP

B-7: FLUSHING TRAVEL CIRCUIT

B-8: INSTALLATION OF TRAVEL PIPING

C. ASSEMBLY OF MACHINE (PART II)

C-1: INSTALLATION OF LEFT SIDE STEP

C-2: INSTALLATION OF STEP

C-3: INSTALLATION OF HANDRAIL

C-4: INSTALLATION OF STEP (ONLY WHEN INSTALLING HIGH CAB)

C-5: INSTALLATION OF OPERATOR'S CAB ASSEMBLY

C-6: CONNECTION OF ELECTRICAL COMPONENTS IN OPERATOR'S CAB (ONLY WHEN INSTALLING HIGH CAB)

C-7: INSTALLATION OF AIR CONDITIONER (ONLY WHEN INSTALLING HIGH CAB)

C-8: INSTALLATION OF OPERATOR'S SEAT ASSEMBLY (ONLY WHEN INSTALLING HIGH CAB)

C-9: INSTALLATION OF ADDITIONAL REAR VIEW MIRROR (OPTION)

C-10: INSTALLATION OF FOPS (OPTION)

C-11: INSTALLATION OF MUFFLER TAIL PIPE

C-12: INSTALLATION OF COUNTERWEIGHT ASSEMBLY

C-13: EXCHANGING RETURN FILTER (STANDARD PART - SPECIAL FLUSHING PART)

C-14: CHECK OF OIL AND WATER LEVELS

C-15: CHECK CENTRAL MONITOR (CARRY OUT ONLY WHEN MACHINE IS DIVIDED INTO THREE PARTS FOR TRANSPORTATION)

C-16: BLEEDING AIR FROM TRAVEL MOTOR CIRCUIT

C-17: BLEEDING AIR FROM HYDRAULIC IDLER CUSHION CIRCUIT

C-18: ADJUSTMENT OF HYDRAULIC IDLER CUSHION CYLINDER

C-19: ADJUSTING TRACK TENSION

D. PROCEDURE FOR ASSEMBLY OF WORK EQUIPMENT (BACKHOE SPECIFICATION)

D-1: ASSEMBLY OF BOOM ASSEMBLY

D-2: RELEASING PRESSURE FROM HYDRAULIC CIRCUIT

D-3: WORK EQUIPMENT PIPING (BETWEEN CHASSIS AND BOOM) (BETWEEN CHASSIS AND BOOM CYLINDER)

D-4: FLUSHING WORK EQUIPMENT PIPING

D-5: INSTALLATION OF BOOM CYLINDER FOOT PIN

D-6: INSTALLING BOOM CYLINDER HOSES

D-7: INSTALLATION OF BOOM CYLINDER TOP PIN

D-8: INSTALLATION OF ARM CYLINDER FOOT PIN

D-9: WORK EQUIPMENT PIPING (ARM CYLINDER)

D-10: INSTALLATION OF ARM AND ARM CYLINDER TOP PIN

D-11: WORK EQUIPMENT PIPING (BOOM-BUCKET CYLINDER)

D-12: ASSEMBLY OF BUCKET ASSEMBLY

D-13: MAINTENANCE STANDARD

D-14: INSTALLATION OF WORK EQUIPMENT GREASE PIPING

D-15: INSTALLATION OF WORK EQUIPMENT WIRING AND WORK EQUIPMENT HOSE CLAMPS

D-16: BLEEDING AIR FROM CYLINDER

D-17: CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

E. PROCEDURE FOR ASSEMBLY OF WORK EQUIPMENT (FRONT LOADING SHOVEL SPECIFICATION)

E-1: INSTALLATION OF ARM CYLINDER FOOT PIN

E-2: CONNECTION OF BOOM AND ARM

E-3: INSTALLATION OF ARM CYLINDER TOP PIN

E-4: INSTALLATION OF BUCKET CYLINDER FOOT PIN

E-5: CONNECTION OF LINK AND BUCKET CYLINDER TOP PIN

E-6: ASSEMBLY OF BOOM ASSEMBLY

E-7: RELEASING PRESSURE FROM HYDRAULIC CIRCUIT

E-8: WORK EQUIPMENT PIPING (BETWEEN CHASSIS AND BOOM)

E-9: WORK EQUIPMENT PIPING

E-10: FLUSHING WORK EQUIPMENT PIPING

E-11: INSTALLATION OF BOOM CYLINDER FOOT PIN

E-12: INSTALLATION OF BOOM CYLINDER HOSES

E-13: INSTALLATION OF BOOM CYLINDER TOP PIN

E-14: INSTALLATION OF ARM CYLINDER HOSES

E-15: INSTALLATION OF BUCKET CYLINDER PIPING

E-16: INSTALLATION OF BOTTOM DUMP CYLINDER PIPING

E-17: INSTALLATION OF BUCKET ASSEMBLY

E-18: MAINTENANCE STANDARD

E-19: INSTALLATION OF BOTTOM DUMP CYLINDER PIPING

E-20: INSTALLATION OF WORK EQUIPMENT PIPING CLAMPS

E-21: INSTALLATION OF WORKING LAMP

E:22: INSTALLATION OF WORK EQUIPMENT GREASE PIPING

E-23: BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT

E-24: CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

E-25: INSTALLATION OF BOOM FOOT POTENTIOMETER

E-26: INSTALLATION AND ADJUSTMENT OF BOOM TOP POTENTIOMETER (BOOM - ARM JOINT)

E-27: INSTALLATION OF CLAMPS AND COVER FOR BOOM FOOT POTENTIOMETER

E-28: INSTALLATION OF CLAMPS AND COVER FOR BOOM TOP POTENTIOMETER

E-29: ADJUSTMENT OF WORK EQUIPMENT CONTROLLER (FOR AUTOMATIC CONTROL OF LOADING SHOVEL)

F. ASSEMBLY OF MACHINE (PART III)

F-1: EXTENDING TRACK FRAME GAUGE WIDTH (ONLY WHEN DIVIDED INTO THREE PARTS FOR TRANSPORTATION)

F-2: INSTALLATION OF TRAVEL PIPING COVERS

G. CHECK OF ALL PARTS DURING AND AFTER ASSEMBLY

H. PCIOOO-1 55°C AUSTRALIA SPECIFICATION

APPENDIX

FIELD ASSEMBLY INSPECTION REPORT

General

Language

EnglishModel of Truck

PC1000-1, PC1000LC-1, PC1000SE-1Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.