Model

UEBM001701SKU

40246Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA6D102E-2: SEBM010023

$25.00

Language

EnglishModel of Truck

PC210-7K, PC210LC-7K, PC210NLC-7K, PC240LC-7K, PC240NLC-7KRegion

United KingdomType of Document

Workshop ManualType of Truck

Crawler ExcavatorIllustrated factory Workshop Manual for Komatsu Crawler Excavators Models PC210-7K, PC210LC-7K, PC210NLC-7K, PC240LC-7K and PC240NLC-7K.

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (United Kingdom):

PC210-7K (SN: K40001-)

PC210LC-7K (SN: K40001-)

PC210NLC-7K (SN: K40001-)

PC240LC-7K (SN: K40001-)

PC240NLC-7K (SN: K40001-)

Format: PDF, 668 pages

Language: English

Table of Contents:

DIMENSIONS

WORKING RANGES

DIMENSIONS

Working ranges

PC240LC-7K, PC240NLC-7K

SPECIFICATION DIMENSION DRAWINGS

SPECIFICATIONS

WEIGHT TABLE

FUEL, COOLANT, AND LUBRICANTs

ENGINE RELATED PARTS

RADIATOR OIL COOLER AFTERCOOLER

POWER TRAIN

FINAL DRIVE

SWING MACHINERY

SWING CIRCLE

TRACK FRAME RECOIL SPRING

IDLER

CARRIER ROLLER

TRACK ROLLER

TRACK SHOE

hydraulic equipment layout drawing

HYDRAULIC TANK

HYDRAULIC PUMP

CONTROL VALVE

CONTROL VALVE

CLSS

SWING MOTOR

REVERSE PREVENTION VALVE

CENTER SWIVEL JOINT

TRAVEL MOTOR

TRAVEL JUNCTION VALVE

TRAVEL PPC SHUTTLE VALVE

VALVE CONTROL

WORK EQUIPMENT SWING PPC VALVE

TRAVEL PPC VALVE

SERVICE PPC VALVE

SOLENOID VALVE

PPC ACCUMULATOR

return oil filter

BOOM HYDRAULIC DRIFT PREVENTION VALVE

LIFT CHECK VALVE

attachment circuit selector valve

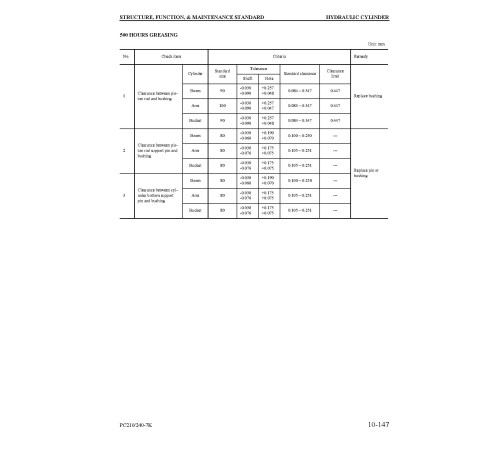

HYDRAULIC CYLINDER

work equipment

air conditioner

ENGINE CONTROL

ELECTRONIC CONTROL SYSTEM

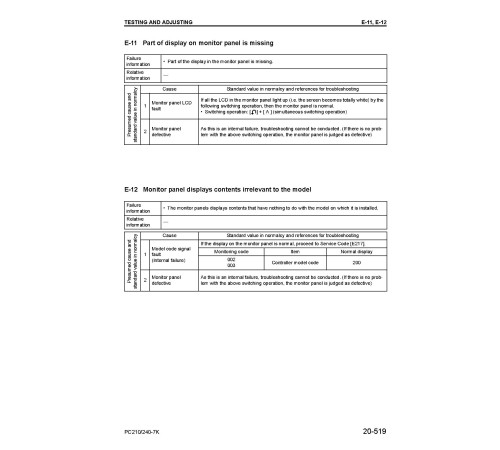

mULTI MONITOR SYSTEM

SENSOR

SELF PRESSURE REDUCING VALVE

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

INSPECTION AND ADJUSTMENT OF ENGINE RPM

MEASUREMENT OF EXHAUST GAS COLOR

ADJUSTMENT OF VALVE CLEARANCE

MEASUREMENT OF COMPRESSION PRESSURE

MEASUREMENT OF BLOW-BY PRESSURE

INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

MEASUREMENT OF ENGINE OIL PRESSURE

ADJUSTMENT OF ENGINE SPEED SENSOR

INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

EMERGENT ESCAPE FROM FAILURE IN ENGINE CONTROL SYSTEM

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION

INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWIN...

INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

INSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE(PC240LC/NLC)

iNSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE(PC210/LC/NLC)

INSPECTION AND ADJUSTMENT OF PUMP LS CONTROL CIRCUIT OIL PRESSURE(pc240lc/nlc)

INSPECTION AND ADJUSTMENT OF PUMP LS CONTROL CIRCUIT OIL PRESSURE(pc210/lc/nlc)

MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE

MEASUREMENT OF PPC VALVE OUTPUT PRESSURE

ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE

INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

RELEASE OF REMAINING PRESSURE IN HYDRAULIC CIRCUIT

MEASUREMENT OF OIL LEAKAGE AMOUNT

AIR BLEEDING OF VARIOUS PARTS

INSPECTION PROCEDURES FOR DIODE

SPECIAL FUNCTION OF MULTI-MONITOR PANEL

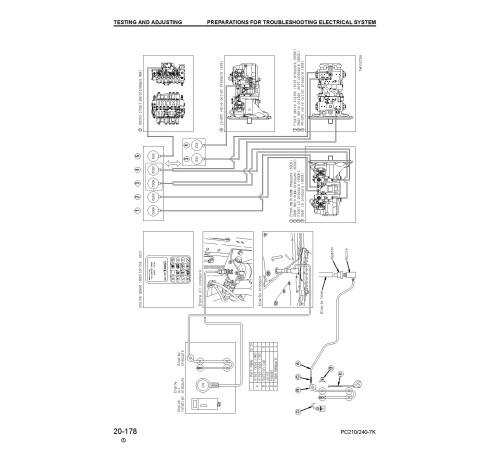

PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

POINTS TO REMEMBER WHEN TROUBLESHOOTING

SEQUENCE OF EVENTS IN TROUBLESHOOTING

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

CHECKS BEFORE TROUBLESHOOTING

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

HOW TO READ THIS MANUAL

PRECAUTIONS WHEN PERFORMING OPERATION

STARTING MOTOR ASSEMBLY

FUEL INJECTION PUMP ASSEMBLY

ENGINE FRONT SEAL

ENGINE REAR SEAL

CYLINDER HEAD ASSEMBLY

RADIATOR ASSEMBLY

HYDRAULIC OIL COOLER ASSEMBLY

ENGINE AND HYDRAULIC PUMP ASSEMBLIES

FINAL DRIVE ASSEMBLY

FINAL DRIVE ASSEMBLY

SKETCHES OF SPECIAL TOOLS

SWING MOTOR AND SWING MACHINERY ASSEMBLY

SWING MOTOR AND SWING MACHINERY ASSEMBLY

CARRIER ROLLER ASSEMBLY

TRACK ROLLER ASSEMBLY

IDLER ASSEMBLY

RECOIL SPRING ASSEMBLY

SPROCKET

TRACK SHOE ASSEMBLY

SWING CIRCLE

ASSEMBLY

REVOLVING FRAME ASSEMBLY

CENTER SWIVEL JOINT ASSEMBLY

CENTER SWIVEL JOINT ASSEMBLY

HYDRAULIC TANK ASSEMBLY

CONTROL VALVE ASSEMBLY

CONTROL VALVE ASSEMBLY

HYDRAULIC PUMP ASSEMBLY

OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT

WORK EQUIPMENT PPC VALVE ASSEMBLY

TRAVEL PPC VALVE ASSEMBLY

HYDRAULIC CYLINDER ASSEMBLY

WORK EQUIPMENT ASSEMBLY

AIR CONDITIONER UNIT ASSEMBLY

COUNTERWEIGHT ASSEMBLY

OPERATORS CAB ASSEMBLY

MONITOR ASSEMBLY

GOVERNOR PUMP CONTROLLER ASSEMBLY

hydraulic circuit diagram

HYDRAULIC diagram

electrical circuit diagram

electrical circuit diagram for air conditioner

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (United Kingdom):

PC210-7K (SN: K40001-)

PC210LC-7K (SN: K40001-)

PC210NLC-7K (SN: K40001-)

PC240LC-7K (SN: K40001-)

PC240NLC-7K (SN: K40001-)

Format: PDF, 668 pages

Language: English

Table of Contents:

DIMENSIONS

WORKING RANGES

DIMENSIONS

Working ranges

PC240LC-7K, PC240NLC-7K

SPECIFICATION DIMENSION DRAWINGS

SPECIFICATIONS

WEIGHT TABLE

FUEL, COOLANT, AND LUBRICANTs

ENGINE RELATED PARTS

RADIATOR OIL COOLER AFTERCOOLER

POWER TRAIN

FINAL DRIVE

SWING MACHINERY

SWING CIRCLE

TRACK FRAME RECOIL SPRING

IDLER

CARRIER ROLLER

TRACK ROLLER

TRACK SHOE

hydraulic equipment layout drawing

HYDRAULIC TANK

HYDRAULIC PUMP

CONTROL VALVE

CONTROL VALVE

CLSS

SWING MOTOR

REVERSE PREVENTION VALVE

CENTER SWIVEL JOINT

TRAVEL MOTOR

TRAVEL JUNCTION VALVE

TRAVEL PPC SHUTTLE VALVE

VALVE CONTROL

WORK EQUIPMENT SWING PPC VALVE

TRAVEL PPC VALVE

SERVICE PPC VALVE

SOLENOID VALVE

PPC ACCUMULATOR

return oil filter

BOOM HYDRAULIC DRIFT PREVENTION VALVE

LIFT CHECK VALVE

attachment circuit selector valve

HYDRAULIC CYLINDER

work equipment

air conditioner

ENGINE CONTROL

ELECTRONIC CONTROL SYSTEM

mULTI MONITOR SYSTEM

SENSOR

SELF PRESSURE REDUCING VALVE

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

INSPECTION AND ADJUSTMENT OF ENGINE RPM

MEASUREMENT OF EXHAUST GAS COLOR

ADJUSTMENT OF VALVE CLEARANCE

MEASUREMENT OF COMPRESSION PRESSURE

MEASUREMENT OF BLOW-BY PRESSURE

INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

MEASUREMENT OF ENGINE OIL PRESSURE

ADJUSTMENT OF ENGINE SPEED SENSOR

INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

EMERGENT ESCAPE FROM FAILURE IN ENGINE CONTROL SYSTEM

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION

INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWIN...

INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

INSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE(PC240LC/NLC)

iNSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE(PC210/LC/NLC)

INSPECTION AND ADJUSTMENT OF PUMP LS CONTROL CIRCUIT OIL PRESSURE(pc240lc/nlc)

INSPECTION AND ADJUSTMENT OF PUMP LS CONTROL CIRCUIT OIL PRESSURE(pc210/lc/nlc)

MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE

MEASUREMENT OF PPC VALVE OUTPUT PRESSURE

ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE

INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

RELEASE OF REMAINING PRESSURE IN HYDRAULIC CIRCUIT

MEASUREMENT OF OIL LEAKAGE AMOUNT

AIR BLEEDING OF VARIOUS PARTS

INSPECTION PROCEDURES FOR DIODE

SPECIAL FUNCTION OF MULTI-MONITOR PANEL

PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

POINTS TO REMEMBER WHEN TROUBLESHOOTING

SEQUENCE OF EVENTS IN TROUBLESHOOTING

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

CHECKS BEFORE TROUBLESHOOTING

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

HOW TO READ THIS MANUAL

PRECAUTIONS WHEN PERFORMING OPERATION

STARTING MOTOR ASSEMBLY

FUEL INJECTION PUMP ASSEMBLY

ENGINE FRONT SEAL

ENGINE REAR SEAL

CYLINDER HEAD ASSEMBLY

RADIATOR ASSEMBLY

HYDRAULIC OIL COOLER ASSEMBLY

ENGINE AND HYDRAULIC PUMP ASSEMBLIES

FINAL DRIVE ASSEMBLY

FINAL DRIVE ASSEMBLY

SKETCHES OF SPECIAL TOOLS

SWING MOTOR AND SWING MACHINERY ASSEMBLY

SWING MOTOR AND SWING MACHINERY ASSEMBLY

CARRIER ROLLER ASSEMBLY

TRACK ROLLER ASSEMBLY

IDLER ASSEMBLY

RECOIL SPRING ASSEMBLY

SPROCKET

TRACK SHOE ASSEMBLY

SWING CIRCLE

ASSEMBLY

REVOLVING FRAME ASSEMBLY

CENTER SWIVEL JOINT ASSEMBLY

CENTER SWIVEL JOINT ASSEMBLY

HYDRAULIC TANK ASSEMBLY

CONTROL VALVE ASSEMBLY

CONTROL VALVE ASSEMBLY

HYDRAULIC PUMP ASSEMBLY

OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT

WORK EQUIPMENT PPC VALVE ASSEMBLY

TRAVEL PPC VALVE ASSEMBLY

HYDRAULIC CYLINDER ASSEMBLY

WORK EQUIPMENT ASSEMBLY

AIR CONDITIONER UNIT ASSEMBLY

COUNTERWEIGHT ASSEMBLY

OPERATORS CAB ASSEMBLY

MONITOR ASSEMBLY

GOVERNOR PUMP CONTROLLER ASSEMBLY

hydraulic circuit diagram

HYDRAULIC diagram

electrical circuit diagram

electrical circuit diagram for air conditioner

General

Language

EnglishModel of Truck

PC210-7K, PC210LC-7K, PC210NLC-7K, PC240LC-7K, PC240NLC-7KRegion

United KingdomType of Document

Workshop ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.