Model

UEBM001801SKU

40247Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA6D140E-3: SEBM022213

$25.00

Language

EnglishModel of Truck

PC750LC-6K, PC750SE-6KRegion

United KingdomType of Document

Workshop ManualType of Truck

Crawler ExcavatorIllustrated factory Workshop Manual for Komatsu Crawler Excavators Models PC750LC-6K and PC750SE-6K.

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (United Kingdom):

PC750LC-6K (SN: K32001-)

PC750SE-6K (SN: K32001-)

Format: PDF, 701 pages

Language: English

Table of Contents:

GENERAL

SPECIFICATION DRAWINGS

FUEL, COOLANT AND LUBRICANTS

PTO

PTO LUBRICATION SYSTEM

POWER TRAIN SWING MACHINERY SWING CIRCLE

FINAL DRIVE

TRACK FRAME AND RECOIL SPRING

IDLER CARRIER ROLLER

TRACK ROLLER

TRACK SHOE ( 1/ 2)

( 2/ 2)

MOTOR GREASE PUMP

HYDRAULIC TANK

HYDRAULIC PUMP

LINE OIL FILTER

PILOT OIL FILTER

DRAIN OIL FILTER

L. H. 5- SPOOL CONTROL VALVE

R. H. 4- SPOOL CONTROL VALVE

STRAIGHT- TRAVEL VALVE

SWING MOTOR

CENTER SWIVEL JOINT

TRAVEL MOTOR

PPC CONTROL RELIEF VALVE

SAFETY LOCK VALVE

PPC ACCUMULATOR

VALVE CONTROL

WORK EQUIPMENT, SWING PPC VALVE

TRAVEL PPC VALVE

SOLENOID VALVE

HYDRAULIC CYLINDER

WORK EQUIPMENT

DIMENSIONS OF WORK EQUIPMENT

AIR CONDITIONER

ENGINE CONTROL

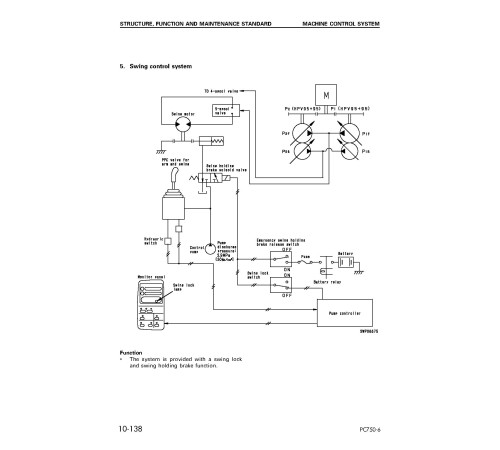

MACHINE CONTROL SYSTEM

MONITOR SYSTEM

SENSORS

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR ENGINE

STANDARD VALUE TABLE FOR CHASSIS

STANDARD VALUE TABLE FOR ELECTRICAL PARTS

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

MEASURING AIR SUPPLY PRESSURE ( BOOST PRESSURE)

MEASURING EXHAUST TEMPERATURE

MEASURING EXHAUST COLOR

ADJUSTING VALVE CLEARANCE

MEASURING BLOW- BY PRESSURE

MEASURING COMPRESSION PRESSURE

MEASURING ENGINE OIL PRESSURE

HANDLING EQUIPMENT IN FUEL CIRCUIT

RELEASING REMAINING PRESSURE IN FUEL SYSTEM

MEASURING FUEL PRESSURE

REDUCED CYLINDER MODE OPERATION FOR ENGINE

BLEEDING AIR FROM FUEL CIRCUIT

CHECKING FOR LEAKAGE IN FUEL CIRCUIT

TESTING AND ADJUSTING ALTERNATOR BELT TENSION

TESTING AND ADJUSTING FAN BELT TENSION

TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR DRIVE BELT TENSION

HANDLING ENGINE CONTROL- LER HIGH VOLTAGE CIRCUIT

ADJUSTING ENGINE SPEED SENSOR

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

TESTING AND ADJUSTING CONTROL PUMP CIRCUIT OIL PRESSURE

TESTING AND ADJUSTING PISTON PUMP CONTROL PRESSURE

MEASURING SERVO PISTON STROKE

MEASURING PPC VALVE OUT- PUT PRESSURE

TESTING SOLENOID VALVE OUTPUT PRESSURE

ADJUSTING WORK EQUIP- MENT, SWING PPC VALVE

TESTING TRAVEL DEVIATION

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

MEASURING OIL LEAKAGE

TESTING CLEARANCE OF SWING CIRCLE BEARING

TESTING AND ADJUSTING TRACK SHOE TENSION

BLEEDING AIR

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

PROCEDURE FOR CHECKING DIODE

POINTS TO REMEMBER WHEN TROUBLESHOOTING

SEQUENCE OF EVENTS IN TROUBLESHOOTING POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE CHECKS BEFORE TROUBLESHOOTING

CONNECTOR TYPES AND MOUNTING LOCATIONS

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM

DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

METHOD OF USING JUDGEMENT TABLE

METHOD OF USING TROUBLESHOOTING CHARTS

DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

N- 1 [ E117, E118 occur at same time ] Monitor panel communication abnormality

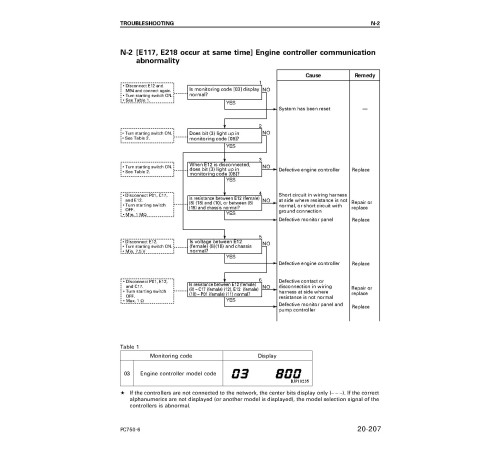

N- 2 [ E117, E218 occur at same time ] Engine controller communication abnormality

N- 3 [ E118, E955 occur at same time ] Pump controller communication abnormality

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED

E- 1 [ E91b ] ( Abnormality in engine speed Ne sensor system) is displayed

E- 2 [ E91C ] ( Abnormality in engine G rotation sensor system) is displayed

E- 3 [ E920 ] ( Abnormality in model selection system) is displayed

E- 4 [ E922 ] ( Engine overrun) is displayed

E- 5 [ E924 ] ( Drop in engine oil pressure) is displayed

E- 6 [ E931 ] ( Abnormality in fuel control dial sensor system) is displayed

E- 7 [ E934 ] ( Abnormality in engine water high- temperature sensor system) is displayed

E- 8 [ E936 ] ( Abnormality in engine oil pressure switch system) is displayed

E- 9 [ E93C ] ( Abnormality in boost pressure sensor system) is displayed

E- 10 [ E93d ] ( Abnormality in fuel temperature sensor system) is displayed

E- 11 [ E954 ] ( Short circuit in starting switch C system) is displayed

[ E955 ] ( Abnormality in network system) is displayed

E- 13 [ E956 ] ( Power source system abnormality 1) is displayed

E- 14 [ E957 ] ( Power source system abnormality 2) is displayed

[ E95A ] ( Abnormality in fuel injection amount adjustment switch signal) is displayed

E- 16 [ E96A ] ( Abnormality in engine water low- temperature sensor system) is displayed

E- 17 [ E970 ] ( Excess current in fuel supply pump PCV1 system) is displayed

E- 18 [ E971 ] ( Excess current in fuel supply pump PCV2 system) is displayed

E- 19 [ E974 ] ( Disconnection in fuel supply pump PCV1 system) is displayed

E- 20 [ E975 ] ( Disconnection in fuel supply pump PCV2 system) is displayed

E- 21 [ E977 ] ( Abnormality in common rail fuel pressure sensor system) is displayed

E- 22 [ E979 ] ( Common rail fuel high pressure abnormality 1) is displayed [ E97A ] ( Common rail fuel high pressure abnormality 2) is displayed

E- 23 [ E97b ] ( Fuel supply pump non- force feed 1) is displayed [ E97C ] ( Fuel supply pump non- force feed 2) is displayed

E- 24 [ E97d ] ( Abnormality in common rail fuel pressure) is displayed

E- 25 [ E980 ] ( Defective engine controller) is displayed

E- 26 [ E981 ] ( Disconnection in No. 1 fuel injector system) is displayed

E- 27 [ E982 ] ( Disconnection in No. 2 fuel injector system) is displayed

E- 28 [ E983 ] ( Disconnection in No. 3 fuel injector system) is displayed

E- 29 [ E984 ] ( Disconnection in No. 4 fuel injector system) is displayed

E- 30 [ E985 ] ( Disconnection in No. 5 fuel injector system) is displayed

E- 31 [ E986 ] ( Disconnection in No. 6 fuel injector system) is displayed

E- 32 [ E98A ] ( Short circuit in No. 1, No. 2, No. 3 fuel injector system) is displayed

E- 33 [ E98b ] ( Short circuit in No. 3, No. 4, No. 5 fuel injector system) is displayed

TROUBLESHOOTING OF PUMP CONTROLLER SYSTEM ( C MODE)

POINTS TO REMEMBER WHEN TROUBLESHOOTING CONTROLLER SYSTEM

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

JUDGEMENT TABLE FOR PUMP CONTROLLER AND HYDRAULIC RELATED PARTS

POINTS TO REMEMBER WHEN TROUBLESHOOTING CONTROLLER SYSTEM

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

JUDGEMENT TABLE FOR PUMP CONTROLLER AND HYDRAULIC RELATED PARTS

C- 1 Abnormality in controller power source system ( controller LED is OFF)

C- 1 Related electrical circuit diagram

TROUBLESHOOTING C- 2

C- 2 [ E232 ] Short circuit in pump TVC solenoid system is displayed

TROUBLESHOOTING C- 2 C- 2 Related electrical circuit diagram TROUBLESHOOTING C- 3

C- 3 [ E233 ] Disconnection in pump TVC solenoid system is displayed

TROUBLESHOOTING C- 3 C- 3 Related electrical circuit diagram TROUBLESHOOTING C- 4

C- 4 [ E203 ] Short circuit in swing holding brake solenoid system is displayed

TROUBLESHOOTING C- 4 C- 4 Related electrical circuit diagram TROUBLESHOOTING C- 5

C- 5 [ E213 ] Disconnection in swing holding brake solenoid system is displayed

TROUBLESHOOTING C- 5 C- 5 Related electrical circuit diagram TROUBLESHOOTING C- 6

C- 6 [ E201 ] Short circuit in CO cancel solenoid system is displayed

C- 6 Related electrical circuit diagram

TROUBLESHOOTING C- 7

C- 7 [ E211 ] Disconnection in CO cancel solenoid system is displayed

C- 7 Related electrical circuit diagram

TROUBLESHOOTING C- 8

C- 8 [ E202 ] Short circuit in straight- travel solenoid system is displayed

C- 8 Related electrical circuit diagram

TROUBLESHOOTING C- 9

C- 9 [ E212 ] Disconnection in straight- travel solenoid system is displayed

C- 9 Related electrical circuit diagram

TROUBLESHOOTING C- 10

C- 10 [ E204 ]

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (United Kingdom):

PC750LC-6K (SN: K32001-)

PC750SE-6K (SN: K32001-)

Format: PDF, 701 pages

Language: English

Table of Contents:

GENERAL

SPECIFICATION DRAWINGS

FUEL, COOLANT AND LUBRICANTS

PTO

PTO LUBRICATION SYSTEM

POWER TRAIN SWING MACHINERY SWING CIRCLE

FINAL DRIVE

TRACK FRAME AND RECOIL SPRING

IDLER CARRIER ROLLER

TRACK ROLLER

TRACK SHOE ( 1/ 2)

( 2/ 2)

MOTOR GREASE PUMP

HYDRAULIC TANK

HYDRAULIC PUMP

LINE OIL FILTER

PILOT OIL FILTER

DRAIN OIL FILTER

L. H. 5- SPOOL CONTROL VALVE

R. H. 4- SPOOL CONTROL VALVE

STRAIGHT- TRAVEL VALVE

SWING MOTOR

CENTER SWIVEL JOINT

TRAVEL MOTOR

PPC CONTROL RELIEF VALVE

SAFETY LOCK VALVE

PPC ACCUMULATOR

VALVE CONTROL

WORK EQUIPMENT, SWING PPC VALVE

TRAVEL PPC VALVE

SOLENOID VALVE

HYDRAULIC CYLINDER

WORK EQUIPMENT

DIMENSIONS OF WORK EQUIPMENT

AIR CONDITIONER

ENGINE CONTROL

MACHINE CONTROL SYSTEM

MONITOR SYSTEM

SENSORS

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR ENGINE

STANDARD VALUE TABLE FOR CHASSIS

STANDARD VALUE TABLE FOR ELECTRICAL PARTS

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

MEASURING AIR SUPPLY PRESSURE ( BOOST PRESSURE)

MEASURING EXHAUST TEMPERATURE

MEASURING EXHAUST COLOR

ADJUSTING VALVE CLEARANCE

MEASURING BLOW- BY PRESSURE

MEASURING COMPRESSION PRESSURE

MEASURING ENGINE OIL PRESSURE

HANDLING EQUIPMENT IN FUEL CIRCUIT

RELEASING REMAINING PRESSURE IN FUEL SYSTEM

MEASURING FUEL PRESSURE

REDUCED CYLINDER MODE OPERATION FOR ENGINE

BLEEDING AIR FROM FUEL CIRCUIT

CHECKING FOR LEAKAGE IN FUEL CIRCUIT

TESTING AND ADJUSTING ALTERNATOR BELT TENSION

TESTING AND ADJUSTING FAN BELT TENSION

TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR DRIVE BELT TENSION

HANDLING ENGINE CONTROL- LER HIGH VOLTAGE CIRCUIT

ADJUSTING ENGINE SPEED SENSOR

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

TESTING AND ADJUSTING CONTROL PUMP CIRCUIT OIL PRESSURE

TESTING AND ADJUSTING PISTON PUMP CONTROL PRESSURE

MEASURING SERVO PISTON STROKE

MEASURING PPC VALVE OUT- PUT PRESSURE

TESTING SOLENOID VALVE OUTPUT PRESSURE

ADJUSTING WORK EQUIP- MENT, SWING PPC VALVE

TESTING TRAVEL DEVIATION

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

MEASURING OIL LEAKAGE

TESTING CLEARANCE OF SWING CIRCLE BEARING

TESTING AND ADJUSTING TRACK SHOE TENSION

BLEEDING AIR

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

PROCEDURE FOR CHECKING DIODE

POINTS TO REMEMBER WHEN TROUBLESHOOTING

SEQUENCE OF EVENTS IN TROUBLESHOOTING POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE CHECKS BEFORE TROUBLESHOOTING

CONNECTOR TYPES AND MOUNTING LOCATIONS

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM

DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

METHOD OF USING JUDGEMENT TABLE

METHOD OF USING TROUBLESHOOTING CHARTS

DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

N- 1 [ E117, E118 occur at same time ] Monitor panel communication abnormality

N- 2 [ E117, E218 occur at same time ] Engine controller communication abnormality

N- 3 [ E118, E955 occur at same time ] Pump controller communication abnormality

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED

E- 1 [ E91b ] ( Abnormality in engine speed Ne sensor system) is displayed

E- 2 [ E91C ] ( Abnormality in engine G rotation sensor system) is displayed

E- 3 [ E920 ] ( Abnormality in model selection system) is displayed

E- 4 [ E922 ] ( Engine overrun) is displayed

E- 5 [ E924 ] ( Drop in engine oil pressure) is displayed

E- 6 [ E931 ] ( Abnormality in fuel control dial sensor system) is displayed

E- 7 [ E934 ] ( Abnormality in engine water high- temperature sensor system) is displayed

E- 8 [ E936 ] ( Abnormality in engine oil pressure switch system) is displayed

E- 9 [ E93C ] ( Abnormality in boost pressure sensor system) is displayed

E- 10 [ E93d ] ( Abnormality in fuel temperature sensor system) is displayed

E- 11 [ E954 ] ( Short circuit in starting switch C system) is displayed

[ E955 ] ( Abnormality in network system) is displayed

E- 13 [ E956 ] ( Power source system abnormality 1) is displayed

E- 14 [ E957 ] ( Power source system abnormality 2) is displayed

[ E95A ] ( Abnormality in fuel injection amount adjustment switch signal) is displayed

E- 16 [ E96A ] ( Abnormality in engine water low- temperature sensor system) is displayed

E- 17 [ E970 ] ( Excess current in fuel supply pump PCV1 system) is displayed

E- 18 [ E971 ] ( Excess current in fuel supply pump PCV2 system) is displayed

E- 19 [ E974 ] ( Disconnection in fuel supply pump PCV1 system) is displayed

E- 20 [ E975 ] ( Disconnection in fuel supply pump PCV2 system) is displayed

E- 21 [ E977 ] ( Abnormality in common rail fuel pressure sensor system) is displayed

E- 22 [ E979 ] ( Common rail fuel high pressure abnormality 1) is displayed [ E97A ] ( Common rail fuel high pressure abnormality 2) is displayed

E- 23 [ E97b ] ( Fuel supply pump non- force feed 1) is displayed [ E97C ] ( Fuel supply pump non- force feed 2) is displayed

E- 24 [ E97d ] ( Abnormality in common rail fuel pressure) is displayed

E- 25 [ E980 ] ( Defective engine controller) is displayed

E- 26 [ E981 ] ( Disconnection in No. 1 fuel injector system) is displayed

E- 27 [ E982 ] ( Disconnection in No. 2 fuel injector system) is displayed

E- 28 [ E983 ] ( Disconnection in No. 3 fuel injector system) is displayed

E- 29 [ E984 ] ( Disconnection in No. 4 fuel injector system) is displayed

E- 30 [ E985 ] ( Disconnection in No. 5 fuel injector system) is displayed

E- 31 [ E986 ] ( Disconnection in No. 6 fuel injector system) is displayed

E- 32 [ E98A ] ( Short circuit in No. 1, No. 2, No. 3 fuel injector system) is displayed

E- 33 [ E98b ] ( Short circuit in No. 3, No. 4, No. 5 fuel injector system) is displayed

TROUBLESHOOTING OF PUMP CONTROLLER SYSTEM ( C MODE)

POINTS TO REMEMBER WHEN TROUBLESHOOTING CONTROLLER SYSTEM

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

JUDGEMENT TABLE FOR PUMP CONTROLLER AND HYDRAULIC RELATED PARTS

POINTS TO REMEMBER WHEN TROUBLESHOOTING CONTROLLER SYSTEM

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

JUDGEMENT TABLE FOR PUMP CONTROLLER AND HYDRAULIC RELATED PARTS

C- 1 Abnormality in controller power source system ( controller LED is OFF)

C- 1 Related electrical circuit diagram

TROUBLESHOOTING C- 2

C- 2 [ E232 ] Short circuit in pump TVC solenoid system is displayed

TROUBLESHOOTING C- 2 C- 2 Related electrical circuit diagram TROUBLESHOOTING C- 3

C- 3 [ E233 ] Disconnection in pump TVC solenoid system is displayed

TROUBLESHOOTING C- 3 C- 3 Related electrical circuit diagram TROUBLESHOOTING C- 4

C- 4 [ E203 ] Short circuit in swing holding brake solenoid system is displayed

TROUBLESHOOTING C- 4 C- 4 Related electrical circuit diagram TROUBLESHOOTING C- 5

C- 5 [ E213 ] Disconnection in swing holding brake solenoid system is displayed

TROUBLESHOOTING C- 5 C- 5 Related electrical circuit diagram TROUBLESHOOTING C- 6

C- 6 [ E201 ] Short circuit in CO cancel solenoid system is displayed

C- 6 Related electrical circuit diagram

TROUBLESHOOTING C- 7

C- 7 [ E211 ] Disconnection in CO cancel solenoid system is displayed

C- 7 Related electrical circuit diagram

TROUBLESHOOTING C- 8

C- 8 [ E202 ] Short circuit in straight- travel solenoid system is displayed

C- 8 Related electrical circuit diagram

TROUBLESHOOTING C- 9

C- 9 [ E212 ] Disconnection in straight- travel solenoid system is displayed

C- 9 Related electrical circuit diagram

TROUBLESHOOTING C- 10

C- 10 [ E204 ]

General

Language

EnglishModel of Truck

PC750LC-6K, PC750SE-6KRegion

United KingdomType of Document

Workshop ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.