Model

UEBM002200SKU

40248Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA4D102E-2: SEBM010023

$25.00

Language

EnglishModel of Truck

PC160LC-7KRegion

WorldWideType of Document

Workshop ManualType of Truck

Crawler ExcavatorIllustrated factory Workshop Manual for Komatsu Crawler Excavators Models PC160LC-7K.

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

PC160LC-7K (SN: K40001-)

Format: PDF, 676 pages

Language: English

Table of Contents:

SAFETY

GENERAL

HOW TO READ THE SHOP MANUAL

HOISTING INSTRUCTIONS

PUSH-PULL TYPE COUPLERS

COATING MATERIALS

STANDARD TIGHTENING TORQUE

ELECTRIC WIRE CODE

CONVERSION TABLES

UNITS

GENERAL

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

TESTING AND ADJUSTING

TOOLS for testing, adjusting and troubleshooting

INSPECTION AND ADJUSTMENT OF ENGINE RPM

MEASUREMENT OF EXHAUST GAS COLOR

ADJUSTMENT OF VALVE CLEARANCE

MEASUREMENT OF COMPRESSION PRESSURE

MEASUREMENT OF BLOW-BY PRESSURE

INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

MEASUREMENT OF ENGINE OIL PRESSURE

ADJUSTMENT OF ENGINE SPEED SENSOR

INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION

Inspection and adjustment oil pressure in work equipment, swing, and INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

INSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE

Inspection and adjustment pump LS control circuit oil pressure

Measurement of solenoid valve output pressure

MEASUREMENT OF PPC VALVE OUTPUT PRESSURE

ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE

INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

TESTING AND ADJUSTING TRAVEL DEVIATION

Release of residual pressure from hydraulic circuit

Measurement of oil leakage

Bleeding air from each part

INSPECTION PROCEDURES FOR DIODE

PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

SPECIAL FUNCTION OF MONITOR PANEL

POINTS TO REMEMBER WHEN TROUBLESHOOTING

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

CHECKS BEFORE TROUBLESHOOTING

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

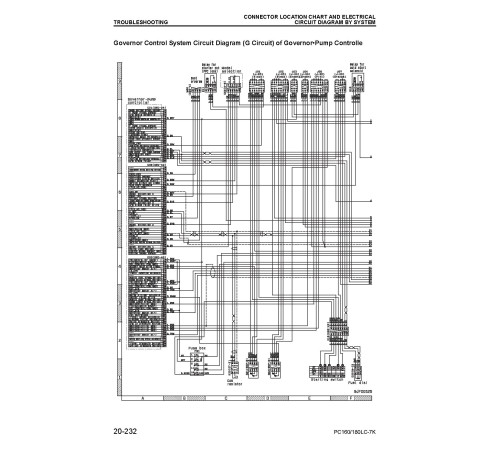

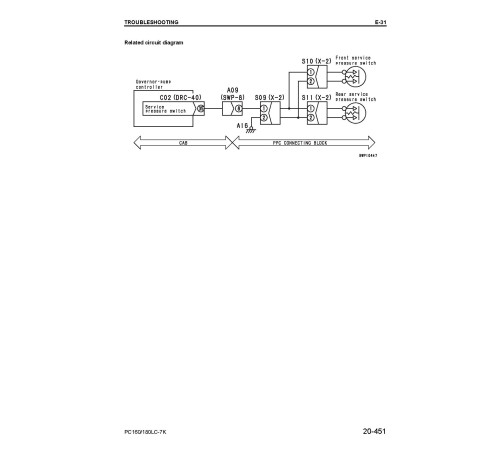

CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

SEQUENCE OF EVENTS IN TROUBLESHOOTING

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

T-adapter - boxes and T-adapter table

Before troubleshooting for displayed code

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

Failure Code in Mechanical System (Abnormally lowered radiator water level)

Failure Code in Mechanical System (Hydraulic oil overheating)

Error Code in Electrical System

Before conducting E-mode troubleshooting

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

H-1 Speed or power of all work equipment, swing, and travel are low

H-2 Engine speed sharply drops or engine stalls

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS

Removal and installation of fuel injection pump assembly

DISASSEMBLY AND ASSEMBLY

HYDRAULIC diagram (1/1)

electrical circuit diagram

electrical circuit diagram for air conditioner

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

PC160LC-7K (SN: K40001-)

Format: PDF, 676 pages

Language: English

Table of Contents:

SAFETY

GENERAL

HOW TO READ THE SHOP MANUAL

HOISTING INSTRUCTIONS

PUSH-PULL TYPE COUPLERS

COATING MATERIALS

STANDARD TIGHTENING TORQUE

ELECTRIC WIRE CODE

CONVERSION TABLES

UNITS

GENERAL

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

TESTING AND ADJUSTING

TOOLS for testing, adjusting and troubleshooting

INSPECTION AND ADJUSTMENT OF ENGINE RPM

MEASUREMENT OF EXHAUST GAS COLOR

ADJUSTMENT OF VALVE CLEARANCE

MEASUREMENT OF COMPRESSION PRESSURE

MEASUREMENT OF BLOW-BY PRESSURE

INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

MEASUREMENT OF ENGINE OIL PRESSURE

ADJUSTMENT OF ENGINE SPEED SENSOR

INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION

Inspection and adjustment oil pressure in work equipment, swing, and INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

INSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE

Inspection and adjustment pump LS control circuit oil pressure

Measurement of solenoid valve output pressure

MEASUREMENT OF PPC VALVE OUTPUT PRESSURE

ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE

INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

TESTING AND ADJUSTING TRAVEL DEVIATION

Release of residual pressure from hydraulic circuit

Measurement of oil leakage

Bleeding air from each part

INSPECTION PROCEDURES FOR DIODE

PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

SPECIAL FUNCTION OF MONITOR PANEL

POINTS TO REMEMBER WHEN TROUBLESHOOTING

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

CHECKS BEFORE TROUBLESHOOTING

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

SEQUENCE OF EVENTS IN TROUBLESHOOTING

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

T-adapter - boxes and T-adapter table

Before troubleshooting for displayed code

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

Failure Code in Mechanical System (Abnormally lowered radiator water level)

Failure Code in Mechanical System (Hydraulic oil overheating)

Error Code in Electrical System

Before conducting E-mode troubleshooting

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

H-1 Speed or power of all work equipment, swing, and travel are low

H-2 Engine speed sharply drops or engine stalls

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS

Removal and installation of fuel injection pump assembly

DISASSEMBLY AND ASSEMBLY

HYDRAULIC diagram (1/1)

electrical circuit diagram

electrical circuit diagram for air conditioner

General

Language

EnglishModel of Truck

PC160LC-7KRegion

WorldWideType of Document

Workshop ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.