Model

WEAM009700SKU

40591Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA6D114E: CEBD000601

$15.00

Language

EnglishModel of Truck

PC80MR-3Region

ItalyType of Document

Operate and Maintenance manualType of Truck

Crawler ExcavatorIllustrated factory Operate and Maintenance manual for Komatsu Crawler Excavators Models PC80MR-3.

This manual will assist you in operating, and maintaining for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Italy):

PC80MR-3 (SN: F00003-)

Format: PDF, 302 pages

Language: English

Table of Contents:

FOREWORD

INFORMATION ON SAFETY

INTRODUCTION

INTENDED USE OF THE MACHINE

IMPROPER OR UNAUTHORIZED USES

RUNNING-IN

POSITIONS AND DIRECTIONS OF THE MACHINE

PRODUCT IDENTIFICATION

MACHINE SERIAL NUMBER

MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN)

ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE

TRAVEL REDUCTION GEAR SERIAL NUMBER

SWING REDUCTION GEAR SERIAL NUMBER

CAB SERIAL NUMBER

SERIAL NUMBERS AND DEALER’S ADDRESS

KOMTRAX SYSTEM

GENERAL PRECAUTIONS

TABLE OF CONTENTS

SAFETY, NOISE AND VIBRATION PLATES

POSITION OF THE SAFETY PLATES

PICTOGRAMS AND RELEVANT MEANINGS

POSITION OF THE NOISE PLATES

VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED

GENERAL PRECAUTIONS

SAFETY RULES

HOW TO BEHAVE IN CASE OF ANOMALIES

CLOTHING AND PERSONAL PROTECTION ITEMS

FIRE EXTINGUISHERS AND FIRST AID KIT

SAFETY DEVICES AND GUARDS

CLEANING THE MACHINE

INSIDE OF THE CAB

LEAVING THE OPERATOR SEAT

GETTING ON AND OFF THE MACHINE

IT IS FORBIDDEN TO CLIMB ON THE EQUIPMENT

ARTICULATED PARTS

PREVENTING BURNS

PREVENTING FIRES DUE TO FUEL AND OIL

HOW TO BEHAVE IN CASE OF FIRE

DETERGENT FOR THE WINDOWS

PROTECTION AGAINST FALLING OBJECTS, FLYING OBJECTS, FOREIGN BODIES

PRECAUTIONS CONCERNING THE EQUIPMENT

COMBINING THE WORK EQUIPMENT

WORK LIGHT AND CAB LIGHTS

CAB WINDOWS

PRECAUTIONS CONCERNING THE CAB STRUCTURE

UNAUTHORIZED MODIFICATIONS

SAFETY AT THE WORKPLACE

WORKING ON LOOSE GROUND

PREVENTING ELECTROCUTION

VISIBILITY

ROOM VENTILATION

CHECKING THE SIGNALS OF THE SIGNALMAN AND THE FIXED SIGNS

HAND SIGNALS

EMERGENCY EXIT

PREVENTING DAMAGE DUE TO ASBESTOS POWDER

PRECAUTIONS FOR USE

BEFORE STARTING THE ENGINE

PRECAUTIONS TO BE TAKEN WHEN WORKING

TRANSPORTING THE MACHINE

BATTERY

REMOVAL

PRECAUTIONS FOR MAINTENANCE

WARNING PLATES

KEEP THE WORK PLACE CLEAN AND ORDERLY

APPOINT A SUPERVISOR WHEN WORKING WITH OTHER PEOPLE

STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION

MAINTENANCE OPERATIONS TO BE CARRIED OUT WITH THE ENGINE RUNNING REQUIRE THE PRESENCE OF TWO OPERATORS

TOOLS

HYDRAULIC ACCUMULATOR

MAINTENANCE STAFF

EQUIPMENT

WORKING UNDER THE MACHINE

NOISE

PRECAUTIONS TO BE TAKEN WHEN USING THE HAMMER

REPAIR WELDS

RULES TO BE FOLLOWED WHEN REFUELLING OR ADDING OIL

CHECKING THE COOLANT LEVEL IN THE RADIATOR

USING LAMPS

PRECAUTIONS TO BE TAKEN WHEN HANDLING THE BATTERY AND THE ALTERNATOR

PRECAUTIONS CONCERNING THE STARTER

PRECAUTIONS TO BE TAKEN WHEN USING HIGH-PRESSURE GREASE TO ADJUST THE TRACK TENSION

DO NOT REMOVE THE SHOCK ABSORBING SPRING FROM THE SHOCK ABSORBER UNIT

PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL

HANDLING HIGH-PRESSURE HOSES

PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE

COOLING FAN AND BELT

WASTE MATERIALS

SERVICING THE AIR CONDITIONER

COMPRESSED AIR

PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY

PRECAUTIONS TO BE TAKEN WHEN HANDLING TECHNOPOLYMERS AND ELASTOMERS

PRECAUTIONS TO BE TAKEN WHEN USING SYNTHETIC BIODEGRADABLE OIL TYPE HEES

DESCRIPTION AND USE OF THE MACHINE

GENERAL VIEW OF THE MACHINE WITH MONOBOOM

GENERAL VIEW OF THE MACHINE WITH TWO-PIECE BOOM

CONTROLS AND INDICATORS

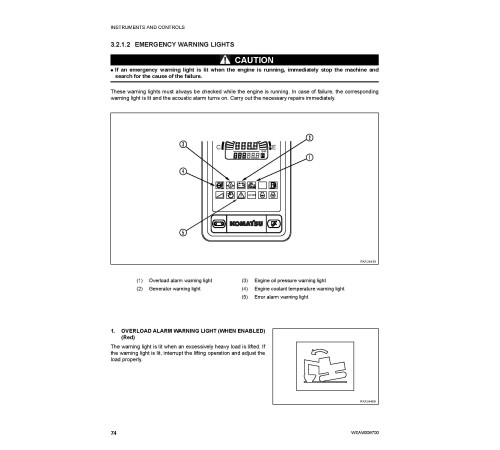

INSTRUMENTS AND CONTROLS

DASHBOARD

SWITCHES AND PUSH BUTTONS

CONTROL LEVERS AND PEDALS

CAB

COVERS WITH LOCK

ENGINE HOOD

TANK COVER

FUSES AND RELAY

CONTROLLER

VENTILATION AND HEATING

AIR CONDITIONER (if installed)

TECHNICAL DOCUMENTATION COMPARTMENT

TOOL BOX

GREASING PUMP SUPPORT

ASHTRAY

FIRE EXTINGUISHERS

FIRST AID KIT

USE OF THE MACHINE

CHECKS TO BE CARRIED OUT BEFORE STARTING THE ENGINE

DAILY CHECKS

ADJUSTMENTS

SEAT BELT

OPERATIONAL CHECKS

STARTING THE ENGINE

AFTER STARTING THE ENGINE

STOPPING THE ENGINE

CHECKS TO BE CARRIED OUT AFTER STOPPING THE ENGINE

OPERATING THE MACHINE

STEERING THE MACHINE

SWINGING THE TURRET

WORK EQUIPMENT CONTROLS AND FUNCTIONS

WORK MODE

UNAUTHORIZED OPERATIONS

IGENERAL INFORMATION ON THE OPERATION OF THE MACHINE

MOVING ON SLOPES

GETTING THE MACHINE OUT OF MUD

OPERATIONS THAT CAN BE PERFORMED WITH THE HYDRAULIC EXCAVATOR

CHANGING THE BUCKET

PARKING THE MACHINE

CHECKS TO BE CARRIED OUT ON THE MACHINE AT THE END OF THE WORK DAY

LOCKING THE MACHINE

ROAD LINERS AND RUBBER TRACKS

TRANSPORTING THE MACHINE

TRANSPORT PROCEDURE

LOADING AND UNLOADING THE MACHINE

HOW TO LIFT THE MACHINE

USING THE MACHINE IN COLD CLIMATES

PRECAUTIONS TO BE TAKEN WHEN USING THE MACHINE IN THE COLD SEASON

AT THE END OF THE WORK DAY

AT THE END OF THE COLD SEASON

LONG PERIODS OF INACTIVITY

BEFORE A PERIOD OF INACTIVITY

DURING A PERIOD OF INACTIVITY

AFTER A PERIOD OF INACTIVITY

TROUBLESHOOTING

IF FUEL RUNS OUT COMPLETELY

OCCURRENCES THAT ARE NOT FAILURES

REMOVING THE MACHINE

DEMANDING OPERATING CONDITIONS

IF THE BATTERY IS DOWN

REMOVING AND INSTALLING THE BATTERY

CHARGING THE BATTERY

STARTING WITH BOOSTER CABLES

LOWERING THE WORK EQUIPMENT WHEN THE ENGINE STOPS BECAUSE OF A FAILURE

OTHER TROUBLES

GUIDE TO MAINTENANCE

MAINTENANCE NOTES

OIL, FUEL AND COOLANT

NOTES ON THE MAINTENANCE OF THE ELECTRICAL SYSTEM

NOTES ON THE MAINTENANCE OF THE HYDRAULIC SYSTEM

MAINTENANCE NOTES REGARDING LUBRICATION

PARTS SUBJECT TO WEAR

LIST OF THE PARTS SUBJECT TO WEAR

FUEL, COOLANT AND LUBRICANTS

COOLANT

APPROVED SYNTHETIC BIODEGRADABLE LUBRICANTS TYPE HEES

TIGHTENING TORQUES

STANDARD TIGHTENING TORQUES FOR SCREWS AND NUTS

STANDARD TIGHTENING TORQUES FOR HOSES WITH ORFS

LUBRICATION

LUBRICATION DIAGRAM

PERIODICAL CHANGE OF SAFETY-RELATED COMPONENTS

SAFETY-RELATED PARTS

MAINTENANCE PLAN

MAINTENANCE PLAN

MAINTENANCE INTERVALS IN CASE OF USE OF THE HYDRAULIC BREAKER

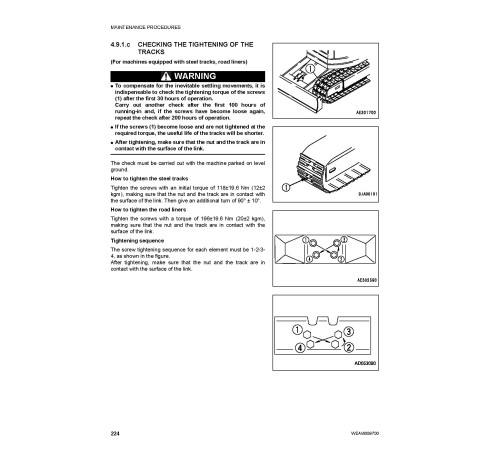

MAINTENANCE PROCEDURES

WHEN REQUIRED

CHECKS TO BE CARRIED OUT BEFORE STARTING THE ENGINE

MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which synthetic biodegradable oil type HEES is used)

MAINTENANCE EVERY 50 HOURS OF OPERATION

MAINTENANCE EVERY 100 HOURS OF OPERATION

MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION

MAINTENANCE EVERY 250 HOURS OF OPERATION

MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which synthetic biodegradable oil type HEES is used)

MAINTENANCE EVERY 500 HOURS OF OPERATION

MAINTENANCE EVERY 1000 HOURS OF OPERATION

MAINTENANCE EVERY 2000 HOURS OF OPERATION

MAINTENANCE EVERY 4000 HOURS OF OPERATION

MAINTENANCE EVERY 5000 HOURS OF OPERATION

TECHNICAL DATA

LIFTING CAPACITIES

LIFTING CAPACITIES WITH MONOBOOM

AUTHORIZED OPTIONAL EQUIPMENT

PRECAUTIONS REGARDING SAFETY

PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT

AUTHORISED TOOLS CHARACTERISTICS

ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER

DESCRIPTION AND CONTROL

USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED

INSTALLING AND REMOVING THE DEMOLITION HAMMER

MAINTENANCE

ARRANGEMENT FOR THE INSTALLATION OF THE CLAMSHELL BUCKET SWING SYSTEM (second hydraulic line)

ARRANGEMENT FOR THE INSTALLATION OF THE BUCKET QUICK COUPLING SYSTEM (Third hydraulic line)

INSTALLING AND REMOVING THE ADDITIONAL COUNTERWEIGHT

This manual will assist you in operating, and maintaining for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Italy):

PC80MR-3 (SN: F00003-)

Format: PDF, 302 pages

Language: English

Table of Contents:

FOREWORD

INFORMATION ON SAFETY

INTRODUCTION

INTENDED USE OF THE MACHINE

IMPROPER OR UNAUTHORIZED USES

RUNNING-IN

POSITIONS AND DIRECTIONS OF THE MACHINE

PRODUCT IDENTIFICATION

MACHINE SERIAL NUMBER

MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN)

ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE

TRAVEL REDUCTION GEAR SERIAL NUMBER

SWING REDUCTION GEAR SERIAL NUMBER

CAB SERIAL NUMBER

SERIAL NUMBERS AND DEALER’S ADDRESS

KOMTRAX SYSTEM

GENERAL PRECAUTIONS

TABLE OF CONTENTS

SAFETY, NOISE AND VIBRATION PLATES

POSITION OF THE SAFETY PLATES

PICTOGRAMS AND RELEVANT MEANINGS

POSITION OF THE NOISE PLATES

VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED

GENERAL PRECAUTIONS

SAFETY RULES

HOW TO BEHAVE IN CASE OF ANOMALIES

CLOTHING AND PERSONAL PROTECTION ITEMS

FIRE EXTINGUISHERS AND FIRST AID KIT

SAFETY DEVICES AND GUARDS

CLEANING THE MACHINE

INSIDE OF THE CAB

LEAVING THE OPERATOR SEAT

GETTING ON AND OFF THE MACHINE

IT IS FORBIDDEN TO CLIMB ON THE EQUIPMENT

ARTICULATED PARTS

PREVENTING BURNS

PREVENTING FIRES DUE TO FUEL AND OIL

HOW TO BEHAVE IN CASE OF FIRE

DETERGENT FOR THE WINDOWS

PROTECTION AGAINST FALLING OBJECTS, FLYING OBJECTS, FOREIGN BODIES

PRECAUTIONS CONCERNING THE EQUIPMENT

COMBINING THE WORK EQUIPMENT

WORK LIGHT AND CAB LIGHTS

CAB WINDOWS

PRECAUTIONS CONCERNING THE CAB STRUCTURE

UNAUTHORIZED MODIFICATIONS

SAFETY AT THE WORKPLACE

WORKING ON LOOSE GROUND

PREVENTING ELECTROCUTION

VISIBILITY

ROOM VENTILATION

CHECKING THE SIGNALS OF THE SIGNALMAN AND THE FIXED SIGNS

HAND SIGNALS

EMERGENCY EXIT

PREVENTING DAMAGE DUE TO ASBESTOS POWDER

PRECAUTIONS FOR USE

BEFORE STARTING THE ENGINE

PRECAUTIONS TO BE TAKEN WHEN WORKING

TRANSPORTING THE MACHINE

BATTERY

REMOVAL

PRECAUTIONS FOR MAINTENANCE

WARNING PLATES

KEEP THE WORK PLACE CLEAN AND ORDERLY

APPOINT A SUPERVISOR WHEN WORKING WITH OTHER PEOPLE

STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION

MAINTENANCE OPERATIONS TO BE CARRIED OUT WITH THE ENGINE RUNNING REQUIRE THE PRESENCE OF TWO OPERATORS

TOOLS

HYDRAULIC ACCUMULATOR

MAINTENANCE STAFF

EQUIPMENT

WORKING UNDER THE MACHINE

NOISE

PRECAUTIONS TO BE TAKEN WHEN USING THE HAMMER

REPAIR WELDS

RULES TO BE FOLLOWED WHEN REFUELLING OR ADDING OIL

CHECKING THE COOLANT LEVEL IN THE RADIATOR

USING LAMPS

PRECAUTIONS TO BE TAKEN WHEN HANDLING THE BATTERY AND THE ALTERNATOR

PRECAUTIONS CONCERNING THE STARTER

PRECAUTIONS TO BE TAKEN WHEN USING HIGH-PRESSURE GREASE TO ADJUST THE TRACK TENSION

DO NOT REMOVE THE SHOCK ABSORBING SPRING FROM THE SHOCK ABSORBER UNIT

PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL

HANDLING HIGH-PRESSURE HOSES

PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE

COOLING FAN AND BELT

WASTE MATERIALS

SERVICING THE AIR CONDITIONER

COMPRESSED AIR

PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY

PRECAUTIONS TO BE TAKEN WHEN HANDLING TECHNOPOLYMERS AND ELASTOMERS

PRECAUTIONS TO BE TAKEN WHEN USING SYNTHETIC BIODEGRADABLE OIL TYPE HEES

DESCRIPTION AND USE OF THE MACHINE

GENERAL VIEW OF THE MACHINE WITH MONOBOOM

GENERAL VIEW OF THE MACHINE WITH TWO-PIECE BOOM

CONTROLS AND INDICATORS

INSTRUMENTS AND CONTROLS

DASHBOARD

SWITCHES AND PUSH BUTTONS

CONTROL LEVERS AND PEDALS

CAB

COVERS WITH LOCK

ENGINE HOOD

TANK COVER

FUSES AND RELAY

CONTROLLER

VENTILATION AND HEATING

AIR CONDITIONER (if installed)

TECHNICAL DOCUMENTATION COMPARTMENT

TOOL BOX

GREASING PUMP SUPPORT

ASHTRAY

FIRE EXTINGUISHERS

FIRST AID KIT

USE OF THE MACHINE

CHECKS TO BE CARRIED OUT BEFORE STARTING THE ENGINE

DAILY CHECKS

ADJUSTMENTS

SEAT BELT

OPERATIONAL CHECKS

STARTING THE ENGINE

AFTER STARTING THE ENGINE

STOPPING THE ENGINE

CHECKS TO BE CARRIED OUT AFTER STOPPING THE ENGINE

OPERATING THE MACHINE

STEERING THE MACHINE

SWINGING THE TURRET

WORK EQUIPMENT CONTROLS AND FUNCTIONS

WORK MODE

UNAUTHORIZED OPERATIONS

IGENERAL INFORMATION ON THE OPERATION OF THE MACHINE

MOVING ON SLOPES

GETTING THE MACHINE OUT OF MUD

OPERATIONS THAT CAN BE PERFORMED WITH THE HYDRAULIC EXCAVATOR

CHANGING THE BUCKET

PARKING THE MACHINE

CHECKS TO BE CARRIED OUT ON THE MACHINE AT THE END OF THE WORK DAY

LOCKING THE MACHINE

ROAD LINERS AND RUBBER TRACKS

TRANSPORTING THE MACHINE

TRANSPORT PROCEDURE

LOADING AND UNLOADING THE MACHINE

HOW TO LIFT THE MACHINE

USING THE MACHINE IN COLD CLIMATES

PRECAUTIONS TO BE TAKEN WHEN USING THE MACHINE IN THE COLD SEASON

AT THE END OF THE WORK DAY

AT THE END OF THE COLD SEASON

LONG PERIODS OF INACTIVITY

BEFORE A PERIOD OF INACTIVITY

DURING A PERIOD OF INACTIVITY

AFTER A PERIOD OF INACTIVITY

TROUBLESHOOTING

IF FUEL RUNS OUT COMPLETELY

OCCURRENCES THAT ARE NOT FAILURES

REMOVING THE MACHINE

DEMANDING OPERATING CONDITIONS

IF THE BATTERY IS DOWN

REMOVING AND INSTALLING THE BATTERY

CHARGING THE BATTERY

STARTING WITH BOOSTER CABLES

LOWERING THE WORK EQUIPMENT WHEN THE ENGINE STOPS BECAUSE OF A FAILURE

OTHER TROUBLES

GUIDE TO MAINTENANCE

MAINTENANCE NOTES

OIL, FUEL AND COOLANT

NOTES ON THE MAINTENANCE OF THE ELECTRICAL SYSTEM

NOTES ON THE MAINTENANCE OF THE HYDRAULIC SYSTEM

MAINTENANCE NOTES REGARDING LUBRICATION

PARTS SUBJECT TO WEAR

LIST OF THE PARTS SUBJECT TO WEAR

FUEL, COOLANT AND LUBRICANTS

COOLANT

APPROVED SYNTHETIC BIODEGRADABLE LUBRICANTS TYPE HEES

TIGHTENING TORQUES

STANDARD TIGHTENING TORQUES FOR SCREWS AND NUTS

STANDARD TIGHTENING TORQUES FOR HOSES WITH ORFS

LUBRICATION

LUBRICATION DIAGRAM

PERIODICAL CHANGE OF SAFETY-RELATED COMPONENTS

SAFETY-RELATED PARTS

MAINTENANCE PLAN

MAINTENANCE PLAN

MAINTENANCE INTERVALS IN CASE OF USE OF THE HYDRAULIC BREAKER

MAINTENANCE PROCEDURES

WHEN REQUIRED

CHECKS TO BE CARRIED OUT BEFORE STARTING THE ENGINE

MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which synthetic biodegradable oil type HEES is used)

MAINTENANCE EVERY 50 HOURS OF OPERATION

MAINTENANCE EVERY 100 HOURS OF OPERATION

MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION

MAINTENANCE EVERY 250 HOURS OF OPERATION

MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which synthetic biodegradable oil type HEES is used)

MAINTENANCE EVERY 500 HOURS OF OPERATION

MAINTENANCE EVERY 1000 HOURS OF OPERATION

MAINTENANCE EVERY 2000 HOURS OF OPERATION

MAINTENANCE EVERY 4000 HOURS OF OPERATION

MAINTENANCE EVERY 5000 HOURS OF OPERATION

TECHNICAL DATA

LIFTING CAPACITIES

LIFTING CAPACITIES WITH MONOBOOM

AUTHORIZED OPTIONAL EQUIPMENT

PRECAUTIONS REGARDING SAFETY

PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT

AUTHORISED TOOLS CHARACTERISTICS

ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER

DESCRIPTION AND CONTROL

USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED

INSTALLING AND REMOVING THE DEMOLITION HAMMER

MAINTENANCE

ARRANGEMENT FOR THE INSTALLATION OF THE CLAMSHELL BUCKET SWING SYSTEM (second hydraulic line)

ARRANGEMENT FOR THE INSTALLATION OF THE BUCKET QUICK COUPLING SYSTEM (Third hydraulic line)

INSTALLING AND REMOVING THE ADDITIONAL COUNTERWEIGHT

General

Language

EnglishModel of Truck

PC80MR-3Region

ItalyType of Document

Operate and Maintenance manualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.