Model

WEBD004000SKU

40592Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA6D114E: CEBD000601

$25.00

Language

EnglishModel of Truck

PC75R-2Region

ItalyType of Document

Workshop ManualType of Truck

Crawler ExcavatorIllustrated factory Workshop Manual for Komatsu Crawler Excavators Models PC75R-2.

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Italy):

PC75R-2 (SN: 22E5200763-)

Format: PDF, 364 pages

Language: English

Table of Contents:

LIST OF REVISED PAGES

SAFETY

FOREWORD

HOW TO READ THE SHOP MANUAL

HOISTING INSTRUCTIONS

STANDARD TIGHTENING TORQUE

COATING MATERIALS

ELECTRIC WIRE CODE

WEIGHT TABLE

TABLE OF OIL COOLANT QUANTITIES

STRUCTURE AND FUNCTION

P.T.O.

POWER TRAIN

TRACK FRAME

IDLER AND RECOIL SPRING

CARRIER ROLLER

TRACK ROLLER

TRACK SHOE

SWING CIRCLE

SWING MACHINERY

HYDRAULIC CIRCUIT DIAGRAM (STANDARD)

HYDRAULIC CIRCUIT DIAGRAM (2-PIECE BOOM)

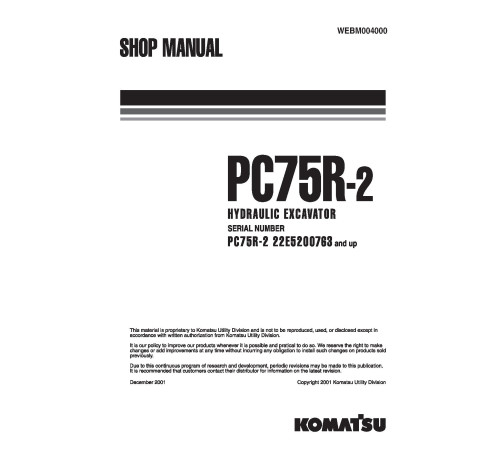

HYDRAULIC PUMP

SPOOL CONTROL VALVE (STANDARD)

SPOOL CONTROL VALVE (STANDARD+2-PIECE BOOM)

SWING MOTOR

CENTER SWIVEL JOINT

TRAVEL MOTOR

PARKING BRAKE

BRAKE VALVE

TRAVEL MOTOR

REDUCTION GEAR

CYLINDERS

SERVOCONTROL FEED UNIT

ACCUMULATOR

PPC VALVE (WORK EQUIPMENT)

PPC VALVE (BLADE, BOOM SWING, 2-PIECE BOOM)

TRAVEL PPC VALVE

BOOM AND ARM SAFETY VALVE

BLADE SAFETY VALVE

PIECE BOOM SAFETY VALVE

OVERLOAD SENSOR SWITCH

SOLENOID VALVE

ELECTRICAL DIAGRAM (1/3)

ELECTRICAL DIAGRAM (2/3)

ELECTRICAL DIAGRAM (3/3)

TESTING AND ADJUSTING

NORMAL OR STANDARD TECHNICAL DATA

SPECIAL TOOLS

MEASURING THE ENGINE SPEED

ADJUSTING VALVE CLEARANCE

MEASURING COMPRESSION PRESSURE

TESTING AND ADJUSTING FUEL INJECTION TIMING

TESTING AND ADJUSTING FAN BELT TENSION

ADJUSTING THE STROKE OF THE ACCELERATOR LEVER

ADJUSTING PPC VALVE CLEARANCE

ADJUSTING THE SAFETY MICROSWITCH

MEASURING THE SWING CIRCLE AXIAL CLEARANCE

TESTING AND ADJUSTING TRACK-SHOE TENSION

AIR BLEEDING FROM HYDRAULIC CIRCUITS

RELEASING RESIDUAL PRESSURE FROM THE CIRCUITS

CHECKING AND REGULATING PRESSURE IN THE HYDRAULIC CIRCUITS

TESTING AND SETTING OF MAIN VALVES

ADJUSTING PC VALVE

MEASURING LS DIFFERENTIAL PRESSURE AND ADJUSTING LS VALVE

CHECKING AND ADJUSTING PRESSURES IN THE SERVOCONTROL FEED UNIT

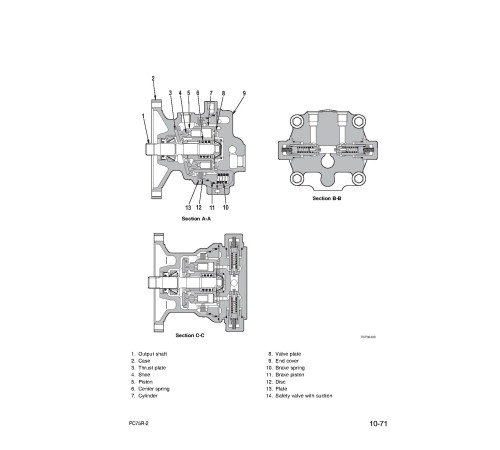

MEASURING PUMPS DELIVERY AND FLOW CONTROL STARTING POINT PUMP P1

MEASURING TRAVEL DEVIATION

ADJUSTING THE MAXIMUM SPEED OF THE TRAVEL MOTORS

MEASURING INNER OIL LEAKAGE OF TRAVEL MOTOR

ADJUSTING BOOM AND ARM SAFETY VALVES

ADJUSTING 2nd BOOM SAFETY VALVES

MEASURING AND SETTING OF PRESSURE SWITCH SIGNAL OVERLOAD OPERATION

MEASUREMENT OF INTERNAL OIL LEAKAGES IN THE SWING MOTOR

CHECKING FOR LEAKAGES INSIDE THE SWIVEL JOINT

ANALYSIS OF THE CAUSES OF HYDRAULIC DRIFTS

DISASSEMBLY AND ASSEMBLY

HOW TO READ THE MANUAL

PRECAUTIONS TO BE TAKEN WHEN WORKING

SPECIAL TOOLS

STARTER MOTOR

ALTERNATOR

INJECTION PUMP

NOZZLE HOLDER

CYLINDER HEAD

SEAT

CABIN

ENGINE HOOD

FRONT HOOD

HEATING FAN

RADIATOR

FUEL TANK

HYDRAULIC OIL TANK

ENGINE-PUMP GROUP

PUMP GROUP

ENGINE-PUMP COUPLING JOINT

MAIN PUMP INPUT SHAFT OIL SEAL

GEAR PUMP

SWIVEL JOINT

SWING MOTOR

SWING MACHINERY

CONTROL VALVE

REVOLVING FRAME

COUNTERWEIGHT

SWING CIRCLE

TRACK SHOES

SPROCKET ASSEMBLY

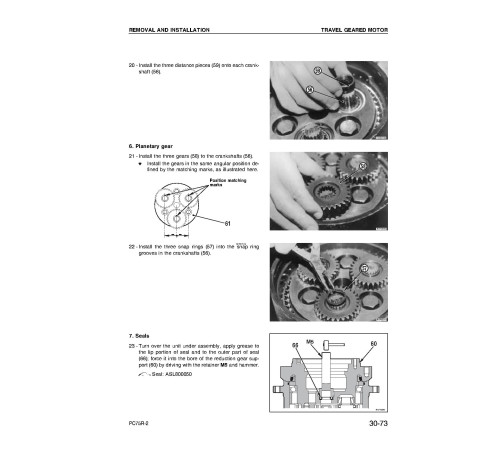

TRAVEL GEAR MOTOR

BALL BEARING PRELOAD

AXIAL CLEARANCE ON TAPERED ROLLER BEARINGS

IDLER AND RECOIL SPRING ASSEMBLY

IDLER

RECOIL SPRING GROUP AND CYLINDER

TRACK ROLLER

CARRIER ROLLER

R.H. PPC VALVE (BOOM-BUCKET)

L.H. PPC VALVE (ARM-SWING)

BLADE PPC VALVE

TRAVEL PEDAL CONTROL

st BOOM SWING PEDAL CONTROL

BOOM CYLINDER (FOR 1-PIECE BOOM)

BOOM CYLINDER (FOR 2-PIECE BOOM)

nd BOOM CYLINDERS

ARM CYLINDER

BUCKET CYLINDER

BOOM SWING CYLINDER

BLADE CYLINDER

WORK EQUIPMENT CYLINDERS

WORK EQUIPMENT (FOR 1-PIECE BOOM)

WORK EQUIPMENT (FOR 2-PIECE BOOM)

BUCKET

ARM

nd BOOM

BOOM (FOR 1-PIECE BOOM)

st BOOM

SWING BRACKET

BLADE

MAINTENANCE STANDARD

P.T.O.

SWING CIRCLE

TRACK FRAME

IDLER

CARRIER ROLLER

TRACK ROLLER

TRACK SHOE

SPROCKET

SWING MACHINERY

HYDRAULIC PUMP

CONTROL VALVE

SWING MOTOR

SWIVEL JOINT

TRAVEL MOTOR

SERVOCONTROL FEED UNIT

TRAVEL PPC VALVE

PPC VALVE

BLADE SAFETY VALVE

CYLINDERS

WORK EQUIPMENT (1-PIECE BOOM)

WORK EQUIPMENT (2-PIECE BOOM)

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Italy):

PC75R-2 (SN: 22E5200763-)

Format: PDF, 364 pages

Language: English

Table of Contents:

LIST OF REVISED PAGES

SAFETY

FOREWORD

HOW TO READ THE SHOP MANUAL

HOISTING INSTRUCTIONS

STANDARD TIGHTENING TORQUE

COATING MATERIALS

ELECTRIC WIRE CODE

WEIGHT TABLE

TABLE OF OIL COOLANT QUANTITIES

STRUCTURE AND FUNCTION

P.T.O.

POWER TRAIN

TRACK FRAME

IDLER AND RECOIL SPRING

CARRIER ROLLER

TRACK ROLLER

TRACK SHOE

SWING CIRCLE

SWING MACHINERY

HYDRAULIC CIRCUIT DIAGRAM (STANDARD)

HYDRAULIC CIRCUIT DIAGRAM (2-PIECE BOOM)

HYDRAULIC PUMP

SPOOL CONTROL VALVE (STANDARD)

SPOOL CONTROL VALVE (STANDARD+2-PIECE BOOM)

SWING MOTOR

CENTER SWIVEL JOINT

TRAVEL MOTOR

PARKING BRAKE

BRAKE VALVE

TRAVEL MOTOR

REDUCTION GEAR

CYLINDERS

SERVOCONTROL FEED UNIT

ACCUMULATOR

PPC VALVE (WORK EQUIPMENT)

PPC VALVE (BLADE, BOOM SWING, 2-PIECE BOOM)

TRAVEL PPC VALVE

BOOM AND ARM SAFETY VALVE

BLADE SAFETY VALVE

PIECE BOOM SAFETY VALVE

OVERLOAD SENSOR SWITCH

SOLENOID VALVE

ELECTRICAL DIAGRAM (1/3)

ELECTRICAL DIAGRAM (2/3)

ELECTRICAL DIAGRAM (3/3)

TESTING AND ADJUSTING

NORMAL OR STANDARD TECHNICAL DATA

SPECIAL TOOLS

MEASURING THE ENGINE SPEED

ADJUSTING VALVE CLEARANCE

MEASURING COMPRESSION PRESSURE

TESTING AND ADJUSTING FUEL INJECTION TIMING

TESTING AND ADJUSTING FAN BELT TENSION

ADJUSTING THE STROKE OF THE ACCELERATOR LEVER

ADJUSTING PPC VALVE CLEARANCE

ADJUSTING THE SAFETY MICROSWITCH

MEASURING THE SWING CIRCLE AXIAL CLEARANCE

TESTING AND ADJUSTING TRACK-SHOE TENSION

AIR BLEEDING FROM HYDRAULIC CIRCUITS

RELEASING RESIDUAL PRESSURE FROM THE CIRCUITS

CHECKING AND REGULATING PRESSURE IN THE HYDRAULIC CIRCUITS

TESTING AND SETTING OF MAIN VALVES

ADJUSTING PC VALVE

MEASURING LS DIFFERENTIAL PRESSURE AND ADJUSTING LS VALVE

CHECKING AND ADJUSTING PRESSURES IN THE SERVOCONTROL FEED UNIT

MEASURING PUMPS DELIVERY AND FLOW CONTROL STARTING POINT PUMP P1

MEASURING TRAVEL DEVIATION

ADJUSTING THE MAXIMUM SPEED OF THE TRAVEL MOTORS

MEASURING INNER OIL LEAKAGE OF TRAVEL MOTOR

ADJUSTING BOOM AND ARM SAFETY VALVES

ADJUSTING 2nd BOOM SAFETY VALVES

MEASURING AND SETTING OF PRESSURE SWITCH SIGNAL OVERLOAD OPERATION

MEASUREMENT OF INTERNAL OIL LEAKAGES IN THE SWING MOTOR

CHECKING FOR LEAKAGES INSIDE THE SWIVEL JOINT

ANALYSIS OF THE CAUSES OF HYDRAULIC DRIFTS

DISASSEMBLY AND ASSEMBLY

HOW TO READ THE MANUAL

PRECAUTIONS TO BE TAKEN WHEN WORKING

SPECIAL TOOLS

STARTER MOTOR

ALTERNATOR

INJECTION PUMP

NOZZLE HOLDER

CYLINDER HEAD

SEAT

CABIN

ENGINE HOOD

FRONT HOOD

HEATING FAN

RADIATOR

FUEL TANK

HYDRAULIC OIL TANK

ENGINE-PUMP GROUP

PUMP GROUP

ENGINE-PUMP COUPLING JOINT

MAIN PUMP INPUT SHAFT OIL SEAL

GEAR PUMP

SWIVEL JOINT

SWING MOTOR

SWING MACHINERY

CONTROL VALVE

REVOLVING FRAME

COUNTERWEIGHT

SWING CIRCLE

TRACK SHOES

SPROCKET ASSEMBLY

TRAVEL GEAR MOTOR

BALL BEARING PRELOAD

AXIAL CLEARANCE ON TAPERED ROLLER BEARINGS

IDLER AND RECOIL SPRING ASSEMBLY

IDLER

RECOIL SPRING GROUP AND CYLINDER

TRACK ROLLER

CARRIER ROLLER

R.H. PPC VALVE (BOOM-BUCKET)

L.H. PPC VALVE (ARM-SWING)

BLADE PPC VALVE

TRAVEL PEDAL CONTROL

st BOOM SWING PEDAL CONTROL

BOOM CYLINDER (FOR 1-PIECE BOOM)

BOOM CYLINDER (FOR 2-PIECE BOOM)

nd BOOM CYLINDERS

ARM CYLINDER

BUCKET CYLINDER

BOOM SWING CYLINDER

BLADE CYLINDER

WORK EQUIPMENT CYLINDERS

WORK EQUIPMENT (FOR 1-PIECE BOOM)

WORK EQUIPMENT (FOR 2-PIECE BOOM)

BUCKET

ARM

nd BOOM

BOOM (FOR 1-PIECE BOOM)

st BOOM

SWING BRACKET

BLADE

MAINTENANCE STANDARD

P.T.O.

SWING CIRCLE

TRACK FRAME

IDLER

CARRIER ROLLER

TRACK ROLLER

TRACK SHOE

SPROCKET

SWING MACHINERY

HYDRAULIC PUMP

CONTROL VALVE

SWING MOTOR

SWIVEL JOINT

TRAVEL MOTOR

SERVOCONTROL FEED UNIT

TRAVEL PPC VALVE

PPC VALVE

BLADE SAFETY VALVE

CYLINDERS

WORK EQUIPMENT (1-PIECE BOOM)

WORK EQUIPMENT (2-PIECE BOOM)

General

Language

EnglishModel of Truck

PC75R-2Region

ItalyType of Document

Workshop ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.