$10.00

Language

EnglishModel of Truck

PC2000-8Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler ExcavatorIllustrated factory Field Assembly Manual for Komatsu Crawler Excavators Models PC2000-8.

This manual will assist you in for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

PC2000-8 (SN: 20001-)

Format: PDF, 332 pages

Language: English

Table of Contents:

FOREWORD

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

DISPOSAL OF REMOVED PARTS

ASSEMBLY PROCEDURE, ASSEMBLY EQUIPMENT AND SCHEDULE

FLOWCHART OF MAIN ASSEMBLY PROCEDURE

KIT LAYOUT DIAGRAM

TRANSPORTATION POSTURES

LIST OF PARTS SENT INDIVIDUALLY

TOOLS AND EQUIPMENT TO BE USED FOR LOCAL ASSEMBLY

TIGHTENING TORQUE

COATING MATERIALS LIST

A. ASSEMBLY OF CHASSIS

C. ASSEMBLY OF BACKHOE

LS. ASSEMBLY OF LOADING SHOVEL WORK EQUIPMENT

LS- 1. Installation of arm cylinder bottom parts

LS- 2. Installation of boom cylinder to machine body

LS- 3. Installation of boom cylinder hoses

LS- 4. Installation of boom cylinder piping

LS- 5. Installation of boom assembly

LS- 6. Installation of boom cylinder head pins

LS- 7. Installation of hose between machine body and boom

LS- 8. Installation of bucket cylinder assembly

LS- 9. Installation of arm assembly

LS-10. Installation of arm cylinder assembly

LS-11. Installation of hoses between boom and arm

LS-12. Installation of bucket cylinder hoses

LS-13. Installation of grease feed hose of bucket cylinder

LS-14. Installation of bucket assembly

LS-15. Installation of arm cylinder junction hoses

LS-16. Installation of bottom dump hose and grease feed hose between arm and bucket

LS-17. Installation of arm dump cushion (proximity switch)

M. INSPECTION AND SERVICING PROCEDURES AFTER ASSEMBLY

M- 1. Inspection of oil levels and coolant levels and using standard of fuel and lubricant

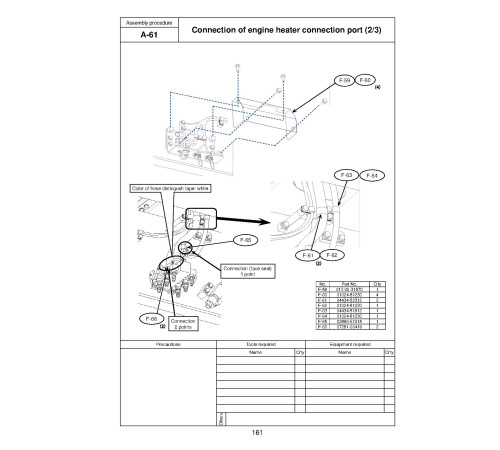

M- 2. Flushing of hydraulic circuit

M- 3. Releasing residual pressure from hydraulic circuit

M- 4. Releasing residual pressure from HIC circuit and check of gas pressure in HIC accumulator

M- 5. Charging air conditioner with refrigerant

M- 6. Installed angles of mirrors

M- 7. Installed angles of lights

VHMS CONTOROLLER INITIAL SETTING PROCEDURE

PC2000-8 Main pump air bleeding check sheet

FIELD ASSEMBLY INSPECTION REPORT (BACKHOE)

FIELD ASSEMBLY INSPECTION REPORT (LOADING SHOVEL)

This manual will assist you in for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

PC2000-8 (SN: 20001-)

Format: PDF, 332 pages

Language: English

Table of Contents:

FOREWORD

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

DISPOSAL OF REMOVED PARTS

ASSEMBLY PROCEDURE, ASSEMBLY EQUIPMENT AND SCHEDULE

FLOWCHART OF MAIN ASSEMBLY PROCEDURE

KIT LAYOUT DIAGRAM

TRANSPORTATION POSTURES

LIST OF PARTS SENT INDIVIDUALLY

TOOLS AND EQUIPMENT TO BE USED FOR LOCAL ASSEMBLY

TIGHTENING TORQUE

COATING MATERIALS LIST

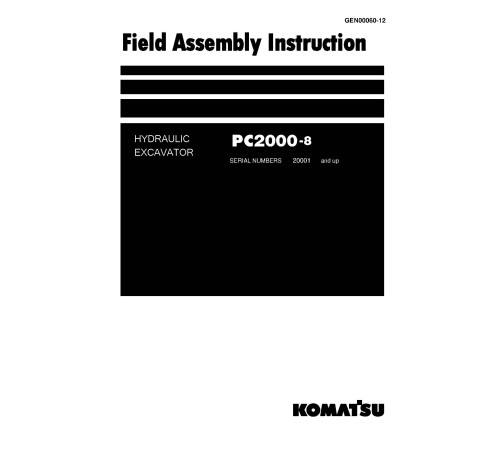

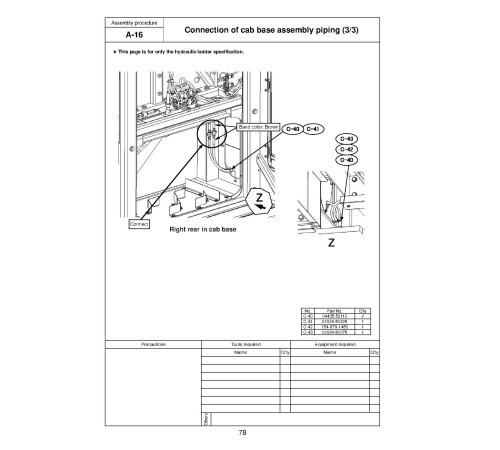

A. ASSEMBLY OF CHASSIS

C. ASSEMBLY OF BACKHOE

LS. ASSEMBLY OF LOADING SHOVEL WORK EQUIPMENT

LS- 1. Installation of arm cylinder bottom parts

LS- 2. Installation of boom cylinder to machine body

LS- 3. Installation of boom cylinder hoses

LS- 4. Installation of boom cylinder piping

LS- 5. Installation of boom assembly

LS- 6. Installation of boom cylinder head pins

LS- 7. Installation of hose between machine body and boom

LS- 8. Installation of bucket cylinder assembly

LS- 9. Installation of arm assembly

LS-10. Installation of arm cylinder assembly

LS-11. Installation of hoses between boom and arm

LS-12. Installation of bucket cylinder hoses

LS-13. Installation of grease feed hose of bucket cylinder

LS-14. Installation of bucket assembly

LS-15. Installation of arm cylinder junction hoses

LS-16. Installation of bottom dump hose and grease feed hose between arm and bucket

LS-17. Installation of arm dump cushion (proximity switch)

M. INSPECTION AND SERVICING PROCEDURES AFTER ASSEMBLY

M- 1. Inspection of oil levels and coolant levels and using standard of fuel and lubricant

M- 2. Flushing of hydraulic circuit

M- 3. Releasing residual pressure from hydraulic circuit

M- 4. Releasing residual pressure from HIC circuit and check of gas pressure in HIC accumulator

M- 5. Charging air conditioner with refrigerant

M- 6. Installed angles of mirrors

M- 7. Installed angles of lights

VHMS CONTOROLLER INITIAL SETTING PROCEDURE

PC2000-8 Main pump air bleeding check sheet

FIELD ASSEMBLY INSPECTION REPORT (BACKHOE)

FIELD ASSEMBLY INSPECTION REPORT (LOADING SHOVEL)

General

Language

EnglishModel of Truck

PC2000-8Region

JapanType of Document

Field Assembly ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.