$25.00

Language

EnglishModel of Truck

PC3000-6Region

GermanyType of Document

Workshop ManualType of Truck

Crawler ExcavatorIllustrated factory Workshop Manual for Komatsu Crawler Excavators Models PC3000-6.

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

PC3000-6 (SN: 6219)

Format: PDF, 497 pages

Language: English

Table of Contents:

I. INTRODUCTION

I.I CONTENTS OF BINDER

I.II FOREWARD

I.III EXPLANATION OF ABBREVATIONS

I.IV TABLE OF CONTENTS

II. SAFETY

II.I SAFETY INSTRUCTIONS

II.II GENERAL PRECAUTIONS

II.III PREPARATIONS FOR WORK

II.IV PRECAUTIONS DURING WORK

III. SPECIFICATIONS

III.I LIFTING GEARS

III.II STANDARD TIGHTENING TORQUE CHART

III.III CONVERSION TABLE

III.IV EXPLANATION OF ABBREVATIONS

III.V GENERAL SPECIFICATIONS

MAIN ASSEMBLY GROUPS

General layout

Superstructure

Power House

Hydraulic Oil Reservoir

Hydraulic Oil Cooler

Fuel tank (Fuel reservoir)

Counter weight

Cab support

Operators cab

Control blocks

Swing gears

Under carriage

DRIVE

Prime drive assembly

Engine and gearbox mount

Torque supports

Radiator fan Drive Assy.

Pump distributor gearbox (PTO)

Coupling

Air Filter

HYDRAULIC OIL RESERVOIR

Hydraulic oil reservoir

Return and leak oil filter

Breather Filter

Location of electrical components

HYDRAULIC OIL COOLING

General

Hydraulic oil cooling circuit

Back pressure valve adjustment

Fan drive

Cooler fan drive adjustment

CONTROLLING

Pilot pressure supply and adjustment

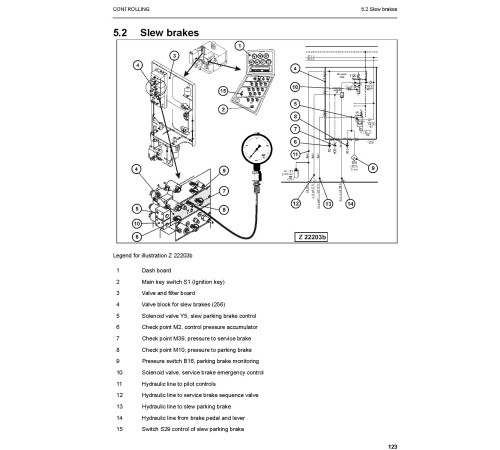

Slew brakes

Travel parking brake

Check of the pilot control logic

COMPONENTS

Main control block and valve arrangement

Distributor manifold

Main control block

Compact valve blocks

Compact valve blocks

Auxiliary gear pumps

Hydraulic cylinder

Swing ring

MAIN HYDRAULIC PUMPS AND PUMP REGULATION

General

Main pump operating principles

Main pump checks and adjustments

Electronic pump regulation

Trouble shooting pump and pump regulation

OPERATING HYDRAULIC

General layout

Floating function of boom and stick only FSA

Check and Adjustments for MRV’s and SRV’s

Hydraulic for the swing circuit

Travel circuit

TRACK TENSION SYSTEM

General layout

Track tensioning function

Truck tensioning adjustment

ACCESS LADDER HYDRAULICALLY OPERATED

Access ladder

Access ladder functional description

CENTRAL REFILLING SYSTEM

Functional description

HINTS FOR READING THE HYDRAULIC CIRCUIT DIAGRAM

General

Symbolic

Hydraulic Diagrams - 942 761 40

HINTS FOR READING THE ELECTRIC CIRCUIT DIAGRAM

Designation of electrical components

Electric symbols

Symbols

Electrical Diagrams - 942 762 40

ELECTRONIC TEXT MONITORING SYSTEM ETM

General Function

AUTOMATIC LUBRICATION SYSTEM

General Function

Function of a lubrication cycle

Lubrication pump drive

Lubrication pump

Lubricant Injector (metering valve)

End line pressure switch

Lubricant in line filter

Lubricant level sensor

Lubrication system function and controlling

Adjustment of the lubrication system with ETM

Trouble shooting lubricating system

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

PC3000-6 (SN: 6219)

Format: PDF, 497 pages

Language: English

Table of Contents:

I. INTRODUCTION

I.I CONTENTS OF BINDER

I.II FOREWARD

I.III EXPLANATION OF ABBREVATIONS

I.IV TABLE OF CONTENTS

II. SAFETY

II.I SAFETY INSTRUCTIONS

II.II GENERAL PRECAUTIONS

II.III PREPARATIONS FOR WORK

II.IV PRECAUTIONS DURING WORK

III. SPECIFICATIONS

III.I LIFTING GEARS

III.II STANDARD TIGHTENING TORQUE CHART

III.III CONVERSION TABLE

III.IV EXPLANATION OF ABBREVATIONS

III.V GENERAL SPECIFICATIONS

MAIN ASSEMBLY GROUPS

General layout

Superstructure

Power House

Hydraulic Oil Reservoir

Hydraulic Oil Cooler

Fuel tank (Fuel reservoir)

Counter weight

Cab support

Operators cab

Control blocks

Swing gears

Under carriage

DRIVE

Prime drive assembly

Engine and gearbox mount

Torque supports

Radiator fan Drive Assy.

Pump distributor gearbox (PTO)

Coupling

Air Filter

HYDRAULIC OIL RESERVOIR

Hydraulic oil reservoir

Return and leak oil filter

Breather Filter

Location of electrical components

HYDRAULIC OIL COOLING

General

Hydraulic oil cooling circuit

Back pressure valve adjustment

Fan drive

Cooler fan drive adjustment

CONTROLLING

Pilot pressure supply and adjustment

Slew brakes

Travel parking brake

Check of the pilot control logic

COMPONENTS

Main control block and valve arrangement

Distributor manifold

Main control block

Compact valve blocks

Compact valve blocks

Auxiliary gear pumps

Hydraulic cylinder

Swing ring

MAIN HYDRAULIC PUMPS AND PUMP REGULATION

General

Main pump operating principles

Main pump checks and adjustments

Electronic pump regulation

Trouble shooting pump and pump regulation

OPERATING HYDRAULIC

General layout

Floating function of boom and stick only FSA

Check and Adjustments for MRV’s and SRV’s

Hydraulic for the swing circuit

Travel circuit

TRACK TENSION SYSTEM

General layout

Track tensioning function

Truck tensioning adjustment

ACCESS LADDER HYDRAULICALLY OPERATED

Access ladder

Access ladder functional description

CENTRAL REFILLING SYSTEM

Functional description

HINTS FOR READING THE HYDRAULIC CIRCUIT DIAGRAM

General

Symbolic

Hydraulic Diagrams - 942 761 40

HINTS FOR READING THE ELECTRIC CIRCUIT DIAGRAM

Designation of electrical components

Electric symbols

Symbols

Electrical Diagrams - 942 762 40

ELECTRONIC TEXT MONITORING SYSTEM ETM

General Function

AUTOMATIC LUBRICATION SYSTEM

General Function

Function of a lubrication cycle

Lubrication pump drive

Lubrication pump

Lubricant Injector (metering valve)

End line pressure switch

Lubricant in line filter

Lubricant level sensor

Lubrication system function and controlling

Adjustment of the lubrication system with ETM

Trouble shooting lubricating system

General

Language

EnglishModel of Truck

PC3000-6Region

GermanyType of Document

Workshop ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.