$25.00

Language

EnglishModel of Truck

PC8000E-6Region

GermanyType of Document

Workshop ManualType of Truck

Crawler ExcavatorIllustrated factory Workshop Manual for Komatsu Crawler Excavators Models PC8000E-6.

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

PC8000E-6 (SN: 12089-12093)

Format: PDF, 768 pages

Language: English

Table of Contents:

INTRODUCTION.

CONTENTS OF THE BINDER

FOREWORD

RECOMMENDATIONS FOR ENVIRONMENTALLY FRIENDLY OPERATION AND MAINTENANCE OF HYDRAULIC MINING SHOVELS

EXPLANATION OF ABBREVIATIONS

DIAGRAMS AND ILLUSTRATIONS IN THIS MANUAL

SAFETY

SAFETY INFORMATION

OVERVIEW

SOUND PRESSURE LEVEL IN THE OPERATOR’S CAB.

GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR

PRECAUTION FOR MAINTENANCE

ADDITIONAL SAFETY INFORMATION FORTROUBLESHOOTING AND ADJUSTMENTS

SPECIAL SAFETY EQUIPMENT

SPECIFICATIONS

LIFTING GEARS

SAFETY HINTS FOR SLING ACCESSORY

STANDARD TIGHTENING TORQUE CHART

CONVERSION TABLE

BLIND PLUGS

CLASSIFICATION OF THREADS TO THE NOMINAL WIDTH

PLUGS AND FITTINGS ACCORDING TO ISO 8434-1 / DIN 2353

MAIN ASSEMBLY GROUPS

GENERAL LAYOUT

SUPERSTRUCTURE

MACHINE HOUSE

HYDRAULIC OIL TANK

HYDRAULIC OIL COOLER

HIGH VOLTAGE SWITCH CABINET

CAB SUPPORT

SLIP RING UNIT

OPERATOR’S CAB

CONTROL BLOCKS

SWING MACHINERY

UNDERCARRIAGE

ATTACHMENTS

DRIVE

ELECTRIC DRIVE - SAFETY AND OPERATION INSTRUCTION DOCUMENTS

PRIME DRIVE ASSEMBLY

ELECTRIC MOTORS

AIR-TO-AIR MOTOR COOLING SYSTEM

INITIAL START-UP PROCEDURE

FLEXIBLE COUPLING

PUMP DISTRIBUTOR GEARBOX (PTO)

HYDRAULIC OIL TANK

GENERAL LAYOUT

LOCATION OF THE ELECTRIC EQUIPMENT

SUCTION OIL TANK WITH STRAINERS

RETURN OIL COLLECTOR PIPE WITH STRAINER

BACK PRESSURE VALVE

TRANSFER PUMP

RETURN AND LEAK OIL FILTER

BREATHER FILTER

HYDRAULIC OIL COOLING

OVERALL VIEW OF THE HYDRAULIC OIL COOLING

FUNCTION OF THE HYDRAULIC OIL COOLING CIRCUIT

ADJUSTMENT OF THE BACK PRESSURE VALVE

FAN DRIVE - STANDARD OIL COOLER

ADJUSTMENT OF THE COOLER FAN DRIVE SPEED

FAN DRIVE - ADDITIONAL OIL COOLER

CONTROLLING

GENERAL LAYOUT

CONTROL AND FILTER PANELS – LOCATION OF COMPONENTS

PILOT PRESSURE SUPPLY AND ADJUSTMENTS

FUNCTION OF THE ELECTRO-HYDRAULIC CONTROL SYSTEM

HAND LEVER (JOYSTICK) CONTROL

FOOT PEDAL CONTROL

PROPORTIONAL AMPLIFIER MODULE, TYPE A

PROPORTIONAL AMPLIFIER MODULE, TYPE B

RAMP TIME MODULE

ADJUSTMENT OF AMPLIFIER MODULES

ADJUSTING THE RAMP TIME MODULE

COMPONENTS

MAIN CONTROL BLOCKS AND HIGH PRESSURE FILTERS (FSA)

DISTRIBUTOR MANIFOLD – LOCATION OF RESTRICTOR BLOCKS AND ANTI-CAVITATION VALVES

RESTRICTOR BLOCK WITH SECONDARY RELIEF VALVE

ANTI-CAVITATION VALVE (ACV) BLOCK

REMOTE CONTROL VALVES

/3 DIRECTIONAL SOLENOID VALVES

PROPORTIONAL SOLENOID VALVES

HIGH-PRESSURE FILTER (SCREEN)

CONTROL BLOCKS AND VALVES

TRAVEL BRAKE VALVE

PRESSURE REDUCING VALVE

/2 DIRECTIONAL VALVES

PRESSURE DOUBLE STAGE VALVE

HYDRAULIC CYLINDER

MAIN HYDRAULIC PUMPS AND PUMP REGULATION

GENERAL

MAIN PUMPS

ELECTRONIC PUMP REGULATION SYSTEM

HYDRAULIC CONSTANT REGULATION SYSTEM (EMERGENCY MODE)

PUMP REGULATION SYSTEM, CHECKSAND ADJUSTMENTS

ENERGY EFFICIENCY

OPERATING HYDRAULICS

GENERAL

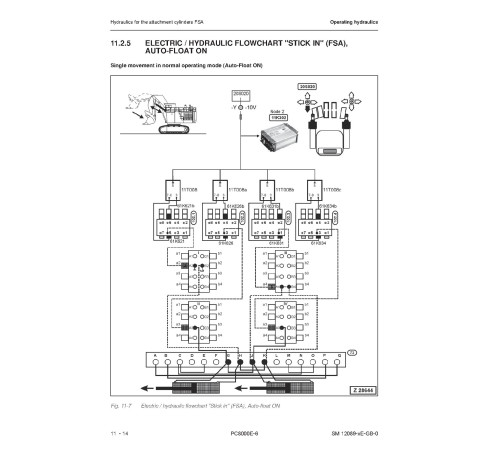

HYDRAULICS FOR THE ATTACHMENT CYLINDERS FSA

HYDRAULICS FOR THE SWING CIRCUIT

HYDRAULICS FOR THE TRAVEL CIRCUIT

HYDRAULIC TRACK TENSIONING SYSTEM

GENERAL

FUNCTIONAL DESCRIPTION

DOUBLE-STAGE VALVE

TENSIONING CYLINDER

ADJUSTMENTS / CHECKS

ACCESS LADDER, HYDRAULICALLY OPERATED

GENERAL

FUNCTION OF THE HYDRAULICALLY OPERATED ACCESS LADDER

ADJUSTMENTS / CHECKS

CENTRAL REFILLING SYSTEM (SERVICE ARM)

SERVICE ARM

MONITORING AND CONTROL BOX

FUNCTION

CHECKS AND ADJUSTMENTS

HINTS FOR READING THE HYDRAULIC DIAGRAM

GENERAL

HYDRAULIC SYMBOLS

HINTS FOR READING THE ELECTRIC WIRING DIAGRAM

GENERAL

REFERENCE CODE OF THE ELECTRICAL COMPONENTS

GRAPHICAL SYMBOLS

DRAWING CONCEPT

CABLE MARKING

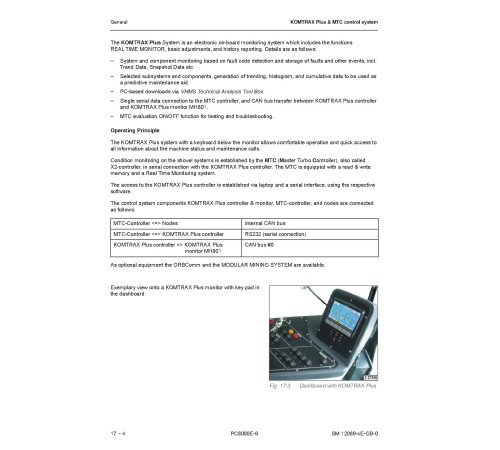

KOMTRAX PLUS & MTC CONTROL SYSTEM

GENERAL

SPECIFICATIONS FOR OPERATORS

TABLES OF ALL PROVIDED MESSAGES

FLOW CHARTS (1-4) OF KOMTRAX PLUS MAIN SCREENS

KOMTRAX PLUS SERVICE LEVEL

INTERFACE-CONNECTION KOMTRAX PLUS CONTROLLER

MTC CONTROL SYSTEM GLOBAL LAYOUT

GLOBAL LAYOUT OF THE INTERNAL CAN BUS

THE NODES IN THE CAN BUS SYSTEM

LUBRICATION SYSTEM

GENERAL OVERVIEW (SLS & CLS1/2)

BASIC FUNCTION OF THE LUBRICATION SYSTEMS

CENTRAL LUBRICATION SYSTEM (CLS 1&2)

SWING CIRCLE LUBRICATION SYSTEM (SLS)

LUBRICATION CYCLE

HYDRAULICALLY DRIVEN LUBE PUMP

LUBRICANT INJECTORS

VENT VALVE

END-LINE SWITCH

IN-LINE FILTER

DESCRIPTION

MAINTENANCE PROCEDURE

LUBRICANT LEVEL SENSOR

COMMISSIONING

DEEP TEMPERATURE EQUIPMENT (OPTION)

GENERAL INFORMATION

PREHEATING PROCEDURE

CONSTANT HEATING OF TRAVEL MOTORS (TTT EQUIPMENT BELOW-40°C ONLY)

COMPONENT LOCATION

COMPONENTS OF TT EQUIPMENT

This manual will assist you in diagnosing, repairing, and adjusting for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

PC8000E-6 (SN: 12089-12093)

Format: PDF, 768 pages

Language: English

Table of Contents:

INTRODUCTION.

CONTENTS OF THE BINDER

FOREWORD

RECOMMENDATIONS FOR ENVIRONMENTALLY FRIENDLY OPERATION AND MAINTENANCE OF HYDRAULIC MINING SHOVELS

EXPLANATION OF ABBREVIATIONS

DIAGRAMS AND ILLUSTRATIONS IN THIS MANUAL

SAFETY

SAFETY INFORMATION

OVERVIEW

SOUND PRESSURE LEVEL IN THE OPERATOR’S CAB.

GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR

PRECAUTION FOR MAINTENANCE

ADDITIONAL SAFETY INFORMATION FORTROUBLESHOOTING AND ADJUSTMENTS

SPECIAL SAFETY EQUIPMENT

SPECIFICATIONS

LIFTING GEARS

SAFETY HINTS FOR SLING ACCESSORY

STANDARD TIGHTENING TORQUE CHART

CONVERSION TABLE

BLIND PLUGS

CLASSIFICATION OF THREADS TO THE NOMINAL WIDTH

PLUGS AND FITTINGS ACCORDING TO ISO 8434-1 / DIN 2353

MAIN ASSEMBLY GROUPS

GENERAL LAYOUT

SUPERSTRUCTURE

MACHINE HOUSE

HYDRAULIC OIL TANK

HYDRAULIC OIL COOLER

HIGH VOLTAGE SWITCH CABINET

CAB SUPPORT

SLIP RING UNIT

OPERATOR’S CAB

CONTROL BLOCKS

SWING MACHINERY

UNDERCARRIAGE

ATTACHMENTS

DRIVE

ELECTRIC DRIVE - SAFETY AND OPERATION INSTRUCTION DOCUMENTS

PRIME DRIVE ASSEMBLY

ELECTRIC MOTORS

AIR-TO-AIR MOTOR COOLING SYSTEM

INITIAL START-UP PROCEDURE

FLEXIBLE COUPLING

PUMP DISTRIBUTOR GEARBOX (PTO)

HYDRAULIC OIL TANK

GENERAL LAYOUT

LOCATION OF THE ELECTRIC EQUIPMENT

SUCTION OIL TANK WITH STRAINERS

RETURN OIL COLLECTOR PIPE WITH STRAINER

BACK PRESSURE VALVE

TRANSFER PUMP

RETURN AND LEAK OIL FILTER

BREATHER FILTER

HYDRAULIC OIL COOLING

OVERALL VIEW OF THE HYDRAULIC OIL COOLING

FUNCTION OF THE HYDRAULIC OIL COOLING CIRCUIT

ADJUSTMENT OF THE BACK PRESSURE VALVE

FAN DRIVE - STANDARD OIL COOLER

ADJUSTMENT OF THE COOLER FAN DRIVE SPEED

FAN DRIVE - ADDITIONAL OIL COOLER

CONTROLLING

GENERAL LAYOUT

CONTROL AND FILTER PANELS – LOCATION OF COMPONENTS

PILOT PRESSURE SUPPLY AND ADJUSTMENTS

FUNCTION OF THE ELECTRO-HYDRAULIC CONTROL SYSTEM

HAND LEVER (JOYSTICK) CONTROL

FOOT PEDAL CONTROL

PROPORTIONAL AMPLIFIER MODULE, TYPE A

PROPORTIONAL AMPLIFIER MODULE, TYPE B

RAMP TIME MODULE

ADJUSTMENT OF AMPLIFIER MODULES

ADJUSTING THE RAMP TIME MODULE

COMPONENTS

MAIN CONTROL BLOCKS AND HIGH PRESSURE FILTERS (FSA)

DISTRIBUTOR MANIFOLD – LOCATION OF RESTRICTOR BLOCKS AND ANTI-CAVITATION VALVES

RESTRICTOR BLOCK WITH SECONDARY RELIEF VALVE

ANTI-CAVITATION VALVE (ACV) BLOCK

REMOTE CONTROL VALVES

/3 DIRECTIONAL SOLENOID VALVES

PROPORTIONAL SOLENOID VALVES

HIGH-PRESSURE FILTER (SCREEN)

CONTROL BLOCKS AND VALVES

TRAVEL BRAKE VALVE

PRESSURE REDUCING VALVE

/2 DIRECTIONAL VALVES

PRESSURE DOUBLE STAGE VALVE

HYDRAULIC CYLINDER

MAIN HYDRAULIC PUMPS AND PUMP REGULATION

GENERAL

MAIN PUMPS

ELECTRONIC PUMP REGULATION SYSTEM

HYDRAULIC CONSTANT REGULATION SYSTEM (EMERGENCY MODE)

PUMP REGULATION SYSTEM, CHECKSAND ADJUSTMENTS

ENERGY EFFICIENCY

OPERATING HYDRAULICS

GENERAL

HYDRAULICS FOR THE ATTACHMENT CYLINDERS FSA

HYDRAULICS FOR THE SWING CIRCUIT

HYDRAULICS FOR THE TRAVEL CIRCUIT

HYDRAULIC TRACK TENSIONING SYSTEM

GENERAL

FUNCTIONAL DESCRIPTION

DOUBLE-STAGE VALVE

TENSIONING CYLINDER

ADJUSTMENTS / CHECKS

ACCESS LADDER, HYDRAULICALLY OPERATED

GENERAL

FUNCTION OF THE HYDRAULICALLY OPERATED ACCESS LADDER

ADJUSTMENTS / CHECKS

CENTRAL REFILLING SYSTEM (SERVICE ARM)

SERVICE ARM

MONITORING AND CONTROL BOX

FUNCTION

CHECKS AND ADJUSTMENTS

HINTS FOR READING THE HYDRAULIC DIAGRAM

GENERAL

HYDRAULIC SYMBOLS

HINTS FOR READING THE ELECTRIC WIRING DIAGRAM

GENERAL

REFERENCE CODE OF THE ELECTRICAL COMPONENTS

GRAPHICAL SYMBOLS

DRAWING CONCEPT

CABLE MARKING

KOMTRAX PLUS & MTC CONTROL SYSTEM

GENERAL

SPECIFICATIONS FOR OPERATORS

TABLES OF ALL PROVIDED MESSAGES

FLOW CHARTS (1-4) OF KOMTRAX PLUS MAIN SCREENS

KOMTRAX PLUS SERVICE LEVEL

INTERFACE-CONNECTION KOMTRAX PLUS CONTROLLER

MTC CONTROL SYSTEM GLOBAL LAYOUT

GLOBAL LAYOUT OF THE INTERNAL CAN BUS

THE NODES IN THE CAN BUS SYSTEM

LUBRICATION SYSTEM

GENERAL OVERVIEW (SLS & CLS1/2)

BASIC FUNCTION OF THE LUBRICATION SYSTEMS

CENTRAL LUBRICATION SYSTEM (CLS 1&2)

SWING CIRCLE LUBRICATION SYSTEM (SLS)

LUBRICATION CYCLE

HYDRAULICALLY DRIVEN LUBE PUMP

LUBRICANT INJECTORS

VENT VALVE

END-LINE SWITCH

IN-LINE FILTER

DESCRIPTION

MAINTENANCE PROCEDURE

LUBRICANT LEVEL SENSOR

COMMISSIONING

DEEP TEMPERATURE EQUIPMENT (OPTION)

GENERAL INFORMATION

PREHEATING PROCEDURE

CONSTANT HEATING OF TRAVEL MOTORS (TTT EQUIPMENT BELOW-40°C ONLY)

COMPONENT LOCATION

COMPONENTS OF TT EQUIPMENT

General

Language

EnglishModel of Truck

PC8000E-6Region

GermanyType of Document

Workshop ManualType of Truck

Crawler ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.