$25.00

Language

EnglishModel of Truck

PW200-7, PW220-7Region

GermanyType of Document

Workshop ManualType of Truck

Wheeled ExcavatorIllustrated factory Workshop Manual for Komatsu Wheeled Excavators Models PW200-7 and PW220-7.

This manual will assist you in diagnosing, repairing, and adjusting for your wheeled excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

PW200-7 (SN: H55051-)

PW220-7 (SN: H65051-)

Format: PDF, 1242 pages

Language: English

Table of Contents:

FOREWORD

Safety

List of revised pages

General

How to read the shop manual

Hoisting instructions

Coating materials

Standard tightening torque

Electric wire code

Conversion tables

Units

GENERAL

Specification dimension drawings

Working ranges

Specifications

Weight table

STRUCTURE AND FUNCTION, MAINTENANCE STANDARD

Engine related parts

Radiator - Oil cooler - Charge air cooler

Power train

Swing circle

Swing machinery and motor

Swing motor

Undercarriage

Transmission

Travel motor

Clutch control circuit

Axle

Suspension lock cylinder

Braking system

Brake/steer pump

Priority valve

Power brake valve

Accumulator for brake system

Steering system

Steering column

Orbitrol valve

Hydraulic equipment layout drawings

Hydraulic circuit diagram

Hydraulic tank

Hydraulic pump

Pilot pressure control (PPC) system

Control valve

CLSS

Centre swivel joint

Travel PPC pedal

Work equipment - Swing PPC valve

Solenoid valves

Boom Safety valve

Hydraulic cylinder

Outrigger cylinder

Dozer cylinder

Work equipment

Air conditioner

Electrical wiring diagram

Electrical system

Engine control system

Machine monitor system

Overload warning device

Sensor

st attachment circuit hydraulic performance (main valve bypassed)

Travel circuit

Steering system

Service brake and suspension system

Quick coupler control valve

ATT EPC valve assembly

KOMTRAX terminal system

Standard value table for engine related parts

Standard value table for chassis related parts

Flow control characteristic of PC valve (STD)

TESTING AND ADJUSTING

Preparations for troubleshooting of electrical system

TESTING AND ADJUSTING

Measuring engine speed

Measuring intake air pressure (boost pressure)

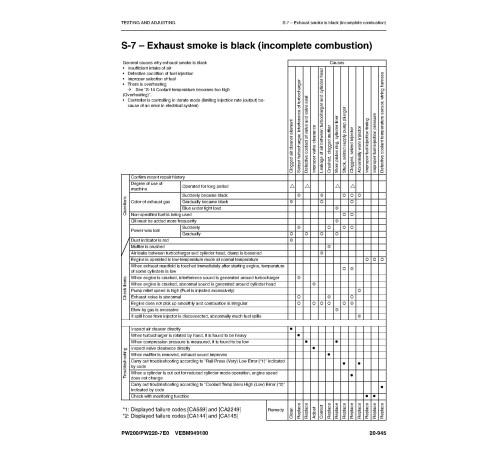

Measurement of exhaust gas color

Adjusting valve clearance

Measuring compression pressure

Measurement of blow-by pressure

Measure engine oil pressure

Handling fuel system parts

Releasing residual pressure from fuel system

Measuring fuel pressure

Measuring fuel return rate and leakage

Bleeding air from fuel circuit

Checking fuel circuit for leakage

Checking and adjusting air conditioner compressor belt tension

Replacing the fan belt

Measurement of clearance in swing circle bearings

Inspection and adjustment of hydraulic oil pressure in hydraulic circuit for work equipment, swing and travel

Inspection and adjustment of control circuit oil pressure

Inspection and adjustment of pump pc (valve inlet) control oil pressure

Inspection and adjustment of pump ls valve control oil pressure

Measurement of solenoid valve output pressure

Measurement of PPC valve output pressure

Adjustment of work equipment and swing PPC valve

Measuring and adjusting quick coupler control valve output pressure

Testing travel motor relief pressure

Adjusting travel motor relief pressure

Testing propshaft speed

Testing transmission clutch control circuit

Inspection of locations of hydraulic drift of work equipment

Release of remaining pressure in hydraulic circuit

Measurement of oil leakage amount

Air bleeding of various parts

Inspection procedures for diode

Special function of monitor panel

Procedure for turning on KOMTRAX terminal

TESTING AND ADJUSTING

Troubleshooting

Points to remember when troubleshooting

Sequence of events in troubleshooting

Points to remember when carrying out maintenance

Checks before troubleshooting

Classification and steps for troubleshooting

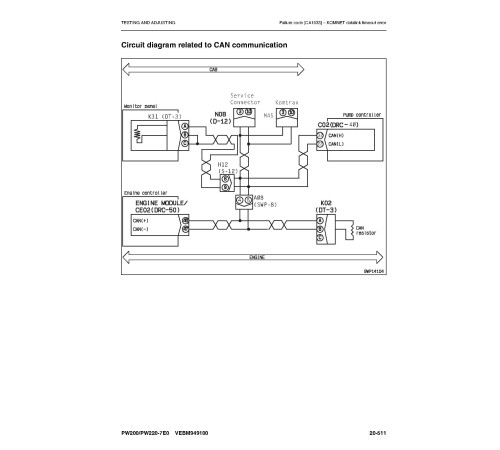

Connector location chart and electrical circuit diagram by system

Connection table for connector pin numbers

Information contained in troubleshooting table

Failure code [6B2JMA] - Abnormality in travel PPC switch hydraulics

Failure code [989L00] - Engine controller lock caution 1

Failure code [989M00] - Engine controller lock caution 2

Failure code [989N00] - Engine controller lock caution 3

Failure code [AA10NX] - Air cleaner clogging

Failure code [AB00KE] - Charging voltage abnormally low

Failure code [B@BAZG] - Abnormally lowered engine oil pressure

Failure code [B@BAZK] - Abnormally lowered engine oil level

Failure code [B@BCNS] - Engine cooling water overheating

Failure code [B@BCZK] - Abnormally low radiator water level

Failure code [B@HANS] - Hydraulic oil overheating

Failure code [CA111] - EMC critical internal failure

Failure code [CA115] - Engine neutral and backup speed sensor error

Failure code [CA122] - Chg air press sensor high error

Failure code [CA123] - Chg air press sensor low error

Failure code [CA131] - Throttle sensor high error

Failure code [CA132] - Throttle sensor low error

Failure code [CA144] - Coolant temp sens high error

Failure code [CA145] - Coolant temp sens low error

Failure code [CA153] - Chg air temp sensor high error

Failure code [CA154] - Chg air temp sensor low error

Failure code [CA155] - Chg air temp high speed derate

Failure code [CA187] - Sens supply 2 volt low error

Failure code [CA221] - Ambient press sens high error

Failure code [CA222] - Ambient press sens low error

Failure code [CA227] - Sens supply 2 volt high error

Failure code [CA234] - Eng overspeed

Failure code [CA238] - Ne speed sens supply volt error

Failure code [CA271] - IMV/PCV1 short error

Failure code [CA272] - IMV/PCV1 open error

Failure code [CA322] - Inj #1 (L#1) open/short error

Failure code [CA323] - Inj #5 (L#5) open/short error

Failure code [CA324] - Inj #3 (L#3) open/short error

Failure code [CA325] - Inj #6 (L#6) open/short error

Failure code [CA331] - Inj #2 (L#2) open/short error

Failure code [CA332] - Inj #4 (L#4) open/short error

Failure code [CA342] - Calibration code incompatibility

Failure code [CA351] - Injectors drive circuit error

Failure code [CA352] - Sens supply 1 volt low error

Failure code [CA386] - Sens supply 1 volt high error

Failure code [CA428] - Water in fuel sensor high error

Failure code [CA429] - Water in fuel sensor low error

Failure code [CA435] - Eng oil press sw error

Failure code [CA441] - Battery voltage low error

Failure code [CA442] - Battery voltage high error

Failure code [CA449] - Rail press very high error

Failure code [CA451] - Rail press sensor high error

Failure code [CA452] - Rail press sensor low error

Failure code [CA488] - Chg air temp high torque derate

Failure code [CA553] - Rail press high error

Failure code [CA559] - Rail press low error

Failure code [CA689] - Eng ne speed sensor error

Failure code [CA731] - Eng bkup speed sens phase error

Failure code [CA757] - All continuous data lost error

Failure code [CA778] - Eng G speed sensor error

Failure code [CA1633] - KOMNET datalink timeout error

Failure code [CA2185] - Throttle sensor supply voltage high error

Failure code [CA2186] - Throttle sensor supply voltage low error

Failure code [CA2249] - Rail press very low error

Failure code [CA2311] - IMV solenoid error

Failure code [CA2555] - Grid htr relay volt high error

Failure code [CA2556] - Grid heater relay volt low error

Failure code [D110KB] - Short-circuiting in battery relay

Failure code [D19JKZ] - Personal code relay abnormality

Failure code [D862KA] - GPS ante

This manual will assist you in diagnosing, repairing, and adjusting for your wheeled excavator.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

PW200-7 (SN: H55051-)

PW220-7 (SN: H65051-)

Format: PDF, 1242 pages

Language: English

Table of Contents:

FOREWORD

Safety

List of revised pages

General

How to read the shop manual

Hoisting instructions

Coating materials

Standard tightening torque

Electric wire code

Conversion tables

Units

GENERAL

Specification dimension drawings

Working ranges

Specifications

Weight table

STRUCTURE AND FUNCTION, MAINTENANCE STANDARD

Engine related parts

Radiator - Oil cooler - Charge air cooler

Power train

Swing circle

Swing machinery and motor

Swing motor

Undercarriage

Transmission

Travel motor

Clutch control circuit

Axle

Suspension lock cylinder

Braking system

Brake/steer pump

Priority valve

Power brake valve

Accumulator for brake system

Steering system

Steering column

Orbitrol valve

Hydraulic equipment layout drawings

Hydraulic circuit diagram

Hydraulic tank

Hydraulic pump

Pilot pressure control (PPC) system

Control valve

CLSS

Centre swivel joint

Travel PPC pedal

Work equipment - Swing PPC valve

Solenoid valves

Boom Safety valve

Hydraulic cylinder

Outrigger cylinder

Dozer cylinder

Work equipment

Air conditioner

Electrical wiring diagram

Electrical system

Engine control system

Machine monitor system

Overload warning device

Sensor

st attachment circuit hydraulic performance (main valve bypassed)

Travel circuit

Steering system

Service brake and suspension system

Quick coupler control valve

ATT EPC valve assembly

KOMTRAX terminal system

Standard value table for engine related parts

Standard value table for chassis related parts

Flow control characteristic of PC valve (STD)

TESTING AND ADJUSTING

Preparations for troubleshooting of electrical system

TESTING AND ADJUSTING

Measuring engine speed

Measuring intake air pressure (boost pressure)

Measurement of exhaust gas color

Adjusting valve clearance

Measuring compression pressure

Measurement of blow-by pressure

Measure engine oil pressure

Handling fuel system parts

Releasing residual pressure from fuel system

Measuring fuel pressure

Measuring fuel return rate and leakage

Bleeding air from fuel circuit

Checking fuel circuit for leakage

Checking and adjusting air conditioner compressor belt tension

Replacing the fan belt

Measurement of clearance in swing circle bearings

Inspection and adjustment of hydraulic oil pressure in hydraulic circuit for work equipment, swing and travel

Inspection and adjustment of control circuit oil pressure

Inspection and adjustment of pump pc (valve inlet) control oil pressure

Inspection and adjustment of pump ls valve control oil pressure

Measurement of solenoid valve output pressure

Measurement of PPC valve output pressure

Adjustment of work equipment and swing PPC valve

Measuring and adjusting quick coupler control valve output pressure

Testing travel motor relief pressure

Adjusting travel motor relief pressure

Testing propshaft speed

Testing transmission clutch control circuit

Inspection of locations of hydraulic drift of work equipment

Release of remaining pressure in hydraulic circuit

Measurement of oil leakage amount

Air bleeding of various parts

Inspection procedures for diode

Special function of monitor panel

Procedure for turning on KOMTRAX terminal

TESTING AND ADJUSTING

Troubleshooting

Points to remember when troubleshooting

Sequence of events in troubleshooting

Points to remember when carrying out maintenance

Checks before troubleshooting

Classification and steps for troubleshooting

Connector location chart and electrical circuit diagram by system

Connection table for connector pin numbers

Information contained in troubleshooting table

Failure code [6B2JMA] - Abnormality in travel PPC switch hydraulics

Failure code [989L00] - Engine controller lock caution 1

Failure code [989M00] - Engine controller lock caution 2

Failure code [989N00] - Engine controller lock caution 3

Failure code [AA10NX] - Air cleaner clogging

Failure code [AB00KE] - Charging voltage abnormally low

Failure code [B@BAZG] - Abnormally lowered engine oil pressure

Failure code [B@BAZK] - Abnormally lowered engine oil level

Failure code [B@BCNS] - Engine cooling water overheating

Failure code [B@BCZK] - Abnormally low radiator water level

Failure code [B@HANS] - Hydraulic oil overheating

Failure code [CA111] - EMC critical internal failure

Failure code [CA115] - Engine neutral and backup speed sensor error

Failure code [CA122] - Chg air press sensor high error

Failure code [CA123] - Chg air press sensor low error

Failure code [CA131] - Throttle sensor high error

Failure code [CA132] - Throttle sensor low error

Failure code [CA144] - Coolant temp sens high error

Failure code [CA145] - Coolant temp sens low error

Failure code [CA153] - Chg air temp sensor high error

Failure code [CA154] - Chg air temp sensor low error

Failure code [CA155] - Chg air temp high speed derate

Failure code [CA187] - Sens supply 2 volt low error

Failure code [CA221] - Ambient press sens high error

Failure code [CA222] - Ambient press sens low error

Failure code [CA227] - Sens supply 2 volt high error

Failure code [CA234] - Eng overspeed

Failure code [CA238] - Ne speed sens supply volt error

Failure code [CA271] - IMV/PCV1 short error

Failure code [CA272] - IMV/PCV1 open error

Failure code [CA322] - Inj #1 (L#1) open/short error

Failure code [CA323] - Inj #5 (L#5) open/short error

Failure code [CA324] - Inj #3 (L#3) open/short error

Failure code [CA325] - Inj #6 (L#6) open/short error

Failure code [CA331] - Inj #2 (L#2) open/short error

Failure code [CA332] - Inj #4 (L#4) open/short error

Failure code [CA342] - Calibration code incompatibility

Failure code [CA351] - Injectors drive circuit error

Failure code [CA352] - Sens supply 1 volt low error

Failure code [CA386] - Sens supply 1 volt high error

Failure code [CA428] - Water in fuel sensor high error

Failure code [CA429] - Water in fuel sensor low error

Failure code [CA435] - Eng oil press sw error

Failure code [CA441] - Battery voltage low error

Failure code [CA442] - Battery voltage high error

Failure code [CA449] - Rail press very high error

Failure code [CA451] - Rail press sensor high error

Failure code [CA452] - Rail press sensor low error

Failure code [CA488] - Chg air temp high torque derate

Failure code [CA553] - Rail press high error

Failure code [CA559] - Rail press low error

Failure code [CA689] - Eng ne speed sensor error

Failure code [CA731] - Eng bkup speed sens phase error

Failure code [CA757] - All continuous data lost error

Failure code [CA778] - Eng G speed sensor error

Failure code [CA1633] - KOMNET datalink timeout error

Failure code [CA2185] - Throttle sensor supply voltage high error

Failure code [CA2186] - Throttle sensor supply voltage low error

Failure code [CA2249] - Rail press very low error

Failure code [CA2311] - IMV solenoid error

Failure code [CA2555] - Grid htr relay volt high error

Failure code [CA2556] - Grid heater relay volt low error

Failure code [D110KB] - Short-circuiting in battery relay

Failure code [D19JKZ] - Personal code relay abnormality

Failure code [D862KA] - GPS ante

General

Language

EnglishModel of Truck

PW200-7, PW220-7Region

GermanyType of Document

Workshop ManualType of Truck

Wheeled ExcavatorReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.