Model

SEBM033208SKU

41800Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: SAA6D102E-2-A: SMEE1020K0

$25.00

Language

EnglishModel of Truck

WA250-5, WA250L-5, WA250PT-5, WA250PTL-5Region

JapanType of Document

Workshop ManualType of Truck

Tool CarierIllustrated factory Workshop Manual for Komatsu 4WD Wheeled Loaders Models WA250-5, WA250L-5, Tool Cariers Models WA250PT-5 and WA250PTL-5.

This manual will assist you in diagnosing, repairing, and adjusting for your 4wd wheeled loader or tool carier.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

WA250-5 4WD Wheeled Loader (SN: 70001-)

WA250L-5 4WD Wheeled Loader (SN: 70001-)

WA250PT-5 Tool Carier (SN: 70001-)

WA250PTL-5 Tool Carier (SN: 70001-)

Format: PDF, 832 pages

Language: English

Table of Contents:

GENERAL

GENERAL ASSEMBLY DRAWINGS

SPECIFICATIONS

WEIGHT TABLE

LIST OF LUBRICANT AND COOLANT

STRUCTURE,FUNCTION AND MAINTENANCE STANDARD

ENGINE MOUNT AND TRANSFER MOUNT

DAMPER

COOLING SYSTEM

TRANSFER OIL COOLER

POWER TRAIN

POWER TRAIN SYSTEM DIAGRAM

DRIVE SHAFT (PROPELLER SHAFT)

HST HYDRAULIC PIPING DIAGRAM

HST PUMP

HIGH-PRESSURE RELIEF VALVE

LOW-PRESSURE RELIEF VALVE

HST CHARGE PUMP

SPEED-RELATED VALVE (DA VALVE)

HIGH-PRESSURE CUT-OFF VALVE

HST MOTOR

EP SERVO VALVE

HA SERVO VALVE

FORWARD-REVERSE SHUTTLE VALVE

TRANSFER

CLUTCH SOLENOID VALVE

AXLE

DIFFERENTIAL

LIMITED-SLIP DIFFERENTIAL

FINAL DRIVE

AXLE MOUNTING AND CENTER HINGE PIN

STEERING PIPING

STEERING COLUMN

PRIORITY VALVE

ORBIT-ROLL VALVE

WAY RESTRICTOR VALVE

CUSHION VALVE

STEERING CYLINDER

EMERGENCY STEERING PIPING

EMERGENCY STEERING VALVE

BRAKE PIPING

BRAKE VALVE

INCHING VALVE

CHARGE VALVE

ACCUMULATOR (FOR BRAKE)

SLACK ADJUSTER

BRAKE

PARKING BRAKE CONTROL

PARKING BRAKE

HYDRAULIC PIPING

HYDRAULIC TANK

GEAR PUMP UNIT

ACCUMULATOR (FOR PPC CIRCUIT)

LOCK VALVE

BYPASS VALVE

QUICK COUPLER VALVE

E.C.S.S. VALVE

ACCUMULATOR (FOR E.C.S.S.)

HYDRAULIC PIPING OF COOLING SYSTEM

COOLING FAN MOTOR

WORK EQUIPMENT CONTROL VALVE

WORK EQUIPMENT PPC VALVE

ATTACHMENT PPC VALVE (IF EQUIPPED)

WORK EQUIPMENT LINKAGE

BUCKET

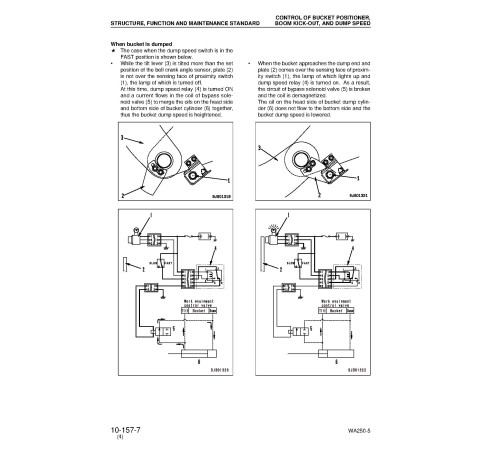

CONTROL OF BUCKET POSITIONER, BOOM KICK-OUT, AND DUMP SPEED

WORK EQUIPMENT CYLINDER

AIR CONDITIONER (IF EQUIPPED)

MACHINE MONITORING SYSTEM

MACHINE MONITOR

LIST OF ITEMS DISPLAYED ON MONITOR

ELECTRICAL SYSTEM (HST CONTROLLER SYSTEM)

HST CONTROLLER

ENGINE START CIRCUIT

ENGINE STOP CIRCUIT

PREHEATING CIRCUIT (AUTOMATIC PREHEATING SYSTEM)

PARKING BRAKE CIRCUIT

ELECTRONICALLY CONTROLLED SUSPENSION SYSTEM

SENSORS

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR ENGINE

STANDARD VALUE TABLE FOR CHASSIS

TESTING AND ADJUSTING

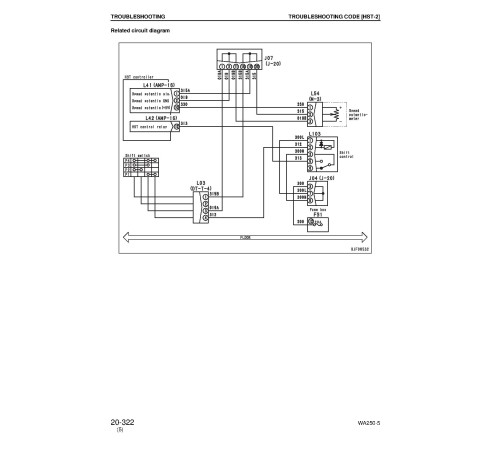

TROUBLESHOOTING

DISASSEMBLY AND ASSEMBLY

HOW TO READ THIS MANUAL

PRECAUTIONS WHEN PERFORMING OPERATION

SPECIAL TOOL LIST

SKETCHES OF SPECIAL TOOLS

REMOVAL, INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

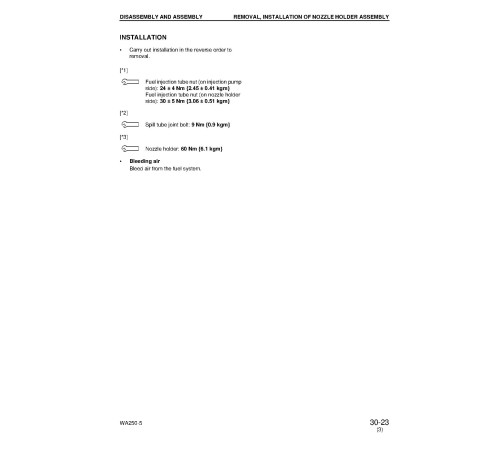

REMOVAL, INSTALLATION OF NOZZLE HOLDER ASSEMBLY

REMOVAL, INSTALLATION OF CYLINDER HEAD ASSEMBLY

REMOVAL, INSTALLATION OF ENGINE ASSEMBLY

REMOVAL, INSTALLATION OF RADIATOR ASSEMBLY

REMOVAL, INSTALLATION OF AIR AFTERCOOLER

REMOVAL, INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY

REMOVAL, INSTALLATION OF COOLING FAN AND FAN MOTOR ASSEMBLY

REMOVAL, INSTALLATION OF FUEL TANK ASSEMBLY

REMOVAL, INSTALLATION OF TRANSFER

DISASSEMBLY, ASSEMBLY OF TRANSFER ASSEMBLY

REMOVAL, INSTALLATION OF PARKING BRAKE ASSEMBLY

DISASSEMBLY, ASSEMBLY OF PARKING BRAKE ASSEMBLY

REMOVAL, INSTALLATION OF FRONT AXLE ASSEMBLY

REMOVAL, INSTALLATION OF REAR AXLE ASSEMBLY

DISASSEMBLY, ASSEMBLY OF AXLE HOUSING ASSEMBLY

DISASSEMBLY, ASSEMBLY OF DIFFERENTIAL ASSEMBLY

DISASSEMBLY AND ASSEMBLY OF HST PUMP ASSEMBLY

DISASSEMBLY AND ASSEMBLY OF HST MOTOR ASSEMBLY

REMOVAL, INSTALLATION OF WORK EQUIPMENT CONTROL VALVE ASSEMBLY

REMOVAL, INSTALLATION OF TRAVEL DAMPER VALVE ASSEMBLY (IF EQUIPPED)

REMOVAL, INSTALLATION OF HYDRAULIC TANK ASSEMBLY

REMOVAL, INSTALLATION OF WORK EQUIPMENT ASSEMBLY

DISASSEMBLY, ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

REMOVAL, INSTALLATION OF OPERATOR`S CAB ASSEMBLY

REMOVAL, INSTALLATION OF OPERATOR`S CAB GLASS (STUCK GLASS)

REMOVAL, NSTALLATION OF CENTER HINGE PIN

REMOVAL, INSTALLATION OF COUNTERWEIGHT

REMOVAL, INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY

REMOVAL, INSTALLATION OF CONDITIONER COMPRESSOR ASSEMBLY

REMOVAL, INSTALLATION OF MONITOR PANEL

REMOVAL, INSTALLATION OF HST CONTROLLER ASSEMBLY

OTHERS

HYDRAULIC CIRCUIT DIAGRAM WA250-5

HYDRAULIC CIRCUIT DIAGRAM WA250PT-5

ELECTRICAL CIRCUIT DIAGRAM 1/4 (1/4) (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 1/4 (2/4) (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CRICUIT DIAGRAM 1/4 (3/4) (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CRICUIT DIAGRAM 1/4 (4/4) (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 2/4 (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 3/4 (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 4/4 (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 1/4 (1/4) (MACHINES EQUIPPED WITH ROPS CANOPY

ELECTRICAL CIRCUIT DIAGRAM 1/4 (2/4) (MACHINES EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 1/4 (3/4) (MACHINE EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 1/4 (4/4) (MACHINE EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 2/4 (MACHINES EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 3/4 (MACHINES EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 4/4 (MACHINES EQUIPPED WITH ROPS CANOPY)

This manual will assist you in diagnosing, repairing, and adjusting for your 4wd wheeled loader or tool carier.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

WA250-5 4WD Wheeled Loader (SN: 70001-)

WA250L-5 4WD Wheeled Loader (SN: 70001-)

WA250PT-5 Tool Carier (SN: 70001-)

WA250PTL-5 Tool Carier (SN: 70001-)

Format: PDF, 832 pages

Language: English

Table of Contents:

GENERAL

GENERAL ASSEMBLY DRAWINGS

SPECIFICATIONS

WEIGHT TABLE

LIST OF LUBRICANT AND COOLANT

STRUCTURE,FUNCTION AND MAINTENANCE STANDARD

ENGINE MOUNT AND TRANSFER MOUNT

DAMPER

COOLING SYSTEM

TRANSFER OIL COOLER

POWER TRAIN

POWER TRAIN SYSTEM DIAGRAM

DRIVE SHAFT (PROPELLER SHAFT)

HST HYDRAULIC PIPING DIAGRAM

HST PUMP

HIGH-PRESSURE RELIEF VALVE

LOW-PRESSURE RELIEF VALVE

HST CHARGE PUMP

SPEED-RELATED VALVE (DA VALVE)

HIGH-PRESSURE CUT-OFF VALVE

HST MOTOR

EP SERVO VALVE

HA SERVO VALVE

FORWARD-REVERSE SHUTTLE VALVE

TRANSFER

CLUTCH SOLENOID VALVE

AXLE

DIFFERENTIAL

LIMITED-SLIP DIFFERENTIAL

FINAL DRIVE

AXLE MOUNTING AND CENTER HINGE PIN

STEERING PIPING

STEERING COLUMN

PRIORITY VALVE

ORBIT-ROLL VALVE

WAY RESTRICTOR VALVE

CUSHION VALVE

STEERING CYLINDER

EMERGENCY STEERING PIPING

EMERGENCY STEERING VALVE

BRAKE PIPING

BRAKE VALVE

INCHING VALVE

CHARGE VALVE

ACCUMULATOR (FOR BRAKE)

SLACK ADJUSTER

BRAKE

PARKING BRAKE CONTROL

PARKING BRAKE

HYDRAULIC PIPING

HYDRAULIC TANK

GEAR PUMP UNIT

ACCUMULATOR (FOR PPC CIRCUIT)

LOCK VALVE

BYPASS VALVE

QUICK COUPLER VALVE

E.C.S.S. VALVE

ACCUMULATOR (FOR E.C.S.S.)

HYDRAULIC PIPING OF COOLING SYSTEM

COOLING FAN MOTOR

WORK EQUIPMENT CONTROL VALVE

WORK EQUIPMENT PPC VALVE

ATTACHMENT PPC VALVE (IF EQUIPPED)

WORK EQUIPMENT LINKAGE

BUCKET

CONTROL OF BUCKET POSITIONER, BOOM KICK-OUT, AND DUMP SPEED

WORK EQUIPMENT CYLINDER

AIR CONDITIONER (IF EQUIPPED)

MACHINE MONITORING SYSTEM

MACHINE MONITOR

LIST OF ITEMS DISPLAYED ON MONITOR

ELECTRICAL SYSTEM (HST CONTROLLER SYSTEM)

HST CONTROLLER

ENGINE START CIRCUIT

ENGINE STOP CIRCUIT

PREHEATING CIRCUIT (AUTOMATIC PREHEATING SYSTEM)

PARKING BRAKE CIRCUIT

ELECTRONICALLY CONTROLLED SUSPENSION SYSTEM

SENSORS

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR ENGINE

STANDARD VALUE TABLE FOR CHASSIS

TESTING AND ADJUSTING

TROUBLESHOOTING

DISASSEMBLY AND ASSEMBLY

HOW TO READ THIS MANUAL

PRECAUTIONS WHEN PERFORMING OPERATION

SPECIAL TOOL LIST

SKETCHES OF SPECIAL TOOLS

REMOVAL, INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

REMOVAL, INSTALLATION OF NOZZLE HOLDER ASSEMBLY

REMOVAL, INSTALLATION OF CYLINDER HEAD ASSEMBLY

REMOVAL, INSTALLATION OF ENGINE ASSEMBLY

REMOVAL, INSTALLATION OF RADIATOR ASSEMBLY

REMOVAL, INSTALLATION OF AIR AFTERCOOLER

REMOVAL, INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY

REMOVAL, INSTALLATION OF COOLING FAN AND FAN MOTOR ASSEMBLY

REMOVAL, INSTALLATION OF FUEL TANK ASSEMBLY

REMOVAL, INSTALLATION OF TRANSFER

DISASSEMBLY, ASSEMBLY OF TRANSFER ASSEMBLY

REMOVAL, INSTALLATION OF PARKING BRAKE ASSEMBLY

DISASSEMBLY, ASSEMBLY OF PARKING BRAKE ASSEMBLY

REMOVAL, INSTALLATION OF FRONT AXLE ASSEMBLY

REMOVAL, INSTALLATION OF REAR AXLE ASSEMBLY

DISASSEMBLY, ASSEMBLY OF AXLE HOUSING ASSEMBLY

DISASSEMBLY, ASSEMBLY OF DIFFERENTIAL ASSEMBLY

DISASSEMBLY AND ASSEMBLY OF HST PUMP ASSEMBLY

DISASSEMBLY AND ASSEMBLY OF HST MOTOR ASSEMBLY

REMOVAL, INSTALLATION OF WORK EQUIPMENT CONTROL VALVE ASSEMBLY

REMOVAL, INSTALLATION OF TRAVEL DAMPER VALVE ASSEMBLY (IF EQUIPPED)

REMOVAL, INSTALLATION OF HYDRAULIC TANK ASSEMBLY

REMOVAL, INSTALLATION OF WORK EQUIPMENT ASSEMBLY

DISASSEMBLY, ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

REMOVAL, INSTALLATION OF OPERATOR`S CAB ASSEMBLY

REMOVAL, INSTALLATION OF OPERATOR`S CAB GLASS (STUCK GLASS)

REMOVAL, NSTALLATION OF CENTER HINGE PIN

REMOVAL, INSTALLATION OF COUNTERWEIGHT

REMOVAL, INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY

REMOVAL, INSTALLATION OF CONDITIONER COMPRESSOR ASSEMBLY

REMOVAL, INSTALLATION OF MONITOR PANEL

REMOVAL, INSTALLATION OF HST CONTROLLER ASSEMBLY

OTHERS

HYDRAULIC CIRCUIT DIAGRAM WA250-5

HYDRAULIC CIRCUIT DIAGRAM WA250PT-5

ELECTRICAL CIRCUIT DIAGRAM 1/4 (1/4) (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 1/4 (2/4) (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CRICUIT DIAGRAM 1/4 (3/4) (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CRICUIT DIAGRAM 1/4 (4/4) (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 2/4 (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 3/4 (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 4/4 (MACHINES EQUIPPED WITH ROPS CAB)

ELECTRICAL CIRCUIT DIAGRAM 1/4 (1/4) (MACHINES EQUIPPED WITH ROPS CANOPY

ELECTRICAL CIRCUIT DIAGRAM 1/4 (2/4) (MACHINES EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 1/4 (3/4) (MACHINE EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 1/4 (4/4) (MACHINE EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 2/4 (MACHINES EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 3/4 (MACHINES EQUIPPED WITH ROPS CANOPY)

ELECTRICAL CIRCUIT DIAGRAM 4/4 (MACHINES EQUIPPED WITH ROPS CANOPY)

General

Language

EnglishModel of Truck

WA250-5, WA250L-5, WA250PT-5, WA250PTL-5Region

JapanType of Document

Workshop ManualType of Truck

Tool CarierReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.