$15.00

Language

EnglishModel of Truck

WA480-6Region

USAType of Document

Operate and Maintenance manualType of Truck

4WD Wheeled LoaderIllustrated factory Operate and Maintenance manual for Komatsu 4WD Wheeled Loaders Models WA480-6.

This manual will assist you in operating, and maintaining for your 4wd wheeled loader.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

WA480-6 (SN: A47001-)

Format: PDF, 426 pages

Language: English

Table of Contents:

FOREWORD

SAFETY INFORMATION

APPROVED AND NON-APPROVED USES

Approved Functions

Non-Approved Functions

VISIBILITY STANDARD

Visibility in Immediate Area

12-M Radius Visibility

Front/Rear, Left/Right Directions of Machine

Machine Serial Number/Product Identification Number (PIN)

Engine Serial Number, EPA Regulations

Position of Service Meter

Serial Numbers and Dealer Information

TABLE OF CONTENTS

SAFETY AND WARNING DECALS

Location of Safety Decals

Safety Labels

GENERAL SAFETY RULES AND PRECAUTIONS

General Safety Rules

General Safety at Job Site

Working on Loose Ground

Safety Features

Personal Protective Equipment

Keep Machine Clean

Fire and Explosion Prevention

Fire Caused by Fuel, Oil, Antifreeze, or Window Washer Fluid

Fire Caused by Accumulation of Flammable Material

Fire Coming from Electric Wiring

Fire Coming from Hydraulic Line

Windshield Washer Fluid

Action If Fire Occurs

Fire Extinguisher and First Aid Kit

Fire Prevention and Suppression

Fire Prevention Steps

Fixed Fire Detection System

Fixed Fire Suppression System

Fire Prevention Procedures

Precautions When Cleaning Cab Glass

Dust Hazards Precautions

Keep Operator's Cab Clean

Unauthorized Modifications

Leaving Operator’s Compartment

Mounting and Dismounting

Crush or Pinch Point Dangers

Inside Operator’s Compartment

Precautions When Using ROPS

Emergency Escape From Operator's Cab

PRECAUTIONS BEFORE STARTING OPERATIONS

Pre-Operational Checks

Starting Your Work Operations

Seat Belt Inspection

Work Site Hazards

Avoiding Dangerous Situations

Working Clearances

Operating on Snow or Icy Surfaces

Precautions in Cold Areas

Asbestos Hazard Alert

RULES FOR ROAD TRAVEL

Traveling in Reverse

Travel on Slopes

Parking the Machine

PRECAUTIONS DURING MAINTENANCE OPERATIONS

Warning Tags

Equipment Storage

Working Under the Machine

Using Drop Lamps

Keeping the Machine Clean

HANDLING TIRES

Precautions When Storing Tires

PERFORMING GENERAL MAINTENANCE PROCEDURES

Running the Engine During Maintenance

Proper Tools

Engine System High-Voltage

Welding, Grinding or Cutting

When Using Hammer

Refueling the Machine

Cooling System Precautions

Battery Precautions

Starting the Machine

High-Pressure Hoses

Safety Handling High-Pressure Hoses

Precaution For High Fuel Pressure

High Temperature Areas

Disposal of Waste Materials

Inflating Tires

Accumulator

Critical Parts

TRANSPORTING THE MACHINE

Loading and Unloading a Trailer

Loading Machine

TOWING THE MACHINE

GENERAL VIEW

General View Of Machine

General View of Controls and Gauges

Machine Monitor

Switch Panel

EXPLANATION OF COMPONENTS

Machine Monitor

Types of Warnings

Emergency Stop

Caution

Mistaken Operation

Inspection and Maintenance

Central Warning Lamp

Character Display Portion

Service Meter

Action Code Display

Failure Code Display

Filter, Oil Replacement Time Display

Emergency Stop Items

Brake Oil Pressure Caution Lamp

Engine Oil Pressure Caution Lamp

Battery Charge Circuit Caution Lamp

Steering Oil Pressure Caution Lamp (if equipped)

Caution Items

Meter Display Portion

Torque Converter Oil Temperature Gauge

Engine Coolant Temperature Gauge

Hydraulic Temperature Gauge

Fuel Gauge

Speedometer

Meter Display Pilot Lamp

OTHER FUNCTIONS OF MACHINE MONITOR

Overall Menu

Displaying Odometer

Resetting Filter, Oil Replacement Time

Entering Telephone Number

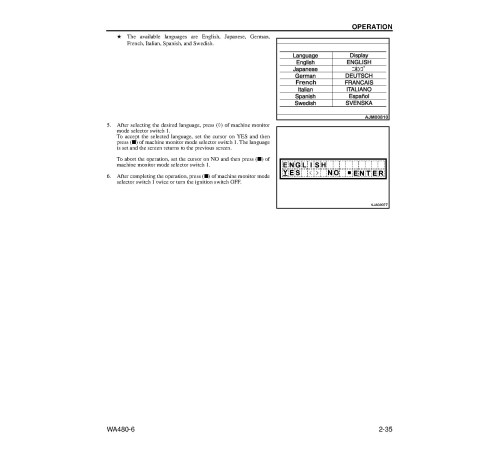

Selecting Language

Adjusting Monitor Brightness

Switching Travel Speed/Engine Speed Display

Switching Travel Speed/Engine Speed Display/Non-Display

SWITCHES AND CONTROLS

General View

Ignition Switch

Power Mode Selector Switch

Transmission Shift Mode Selector Switch

Transmission Cutoff Switch

Transmission Cutoff Set Switch

Lamp Switch

Turn Signal Lever

Dimmer Switch

Horn Button

Hazard Lamp Switch

Parking Brake Switch

Front Working Lamp Switch

Rear Working Lamp Switch

Machine Monitor Mode Selector Switch 1

Machine Monitor Mode Selector Switch 2

Kickdown Switch

Hold Switch

Front Wiper Switch

Rear Wiper Switch

Cigarette Lighter

Room Lamp Switch

Rear Heated Wire Glass Switch

ECSS Switch

Emergency Steering Switch (if equipped)

Cooling Fan Reverse Rotation Switch (If Equipped)

Cooling Fan Auto-Reverse Rotation Switch (If Equipped)

Conditions for Switching Fan Rotation

Torque Converter Lockup Switch (if equipped)

CONTROL LEVERS, PEDALS

General View

Gearshift Lever

Manual Shift

Automatic Shift

Directional Lever

Gearshift Lever Stopper

Work Equipment Lock Lever

Bucket Control Lever

Lift Arm Control Lever

Brake Pedals

Accelerator Pedal

SECURITY LOCKS AND SAFETY FEATURES

Steering Tilt Lock Lever

Frame Lock Bar

Cap with Lock

Fuel Tank Filler Port Cap

Back-Up Alarm

MACHINE FEATURES

Towing Pin

Grease Pump

Cab Door

Emergency Escape Right Door

Left Cab Door, Door Open Lock

Left Cab Door, Knob

Left Cab Door, Handle

Left Cab Sliding Window (Lock Release Knob)

Cab Wiper

ELECTRICAL

Power Outlet

Fuses

Fuse Capacity and Name of Circuit

Slow-Blow Fuse

WORK OPERATIONS

Walk-Around Check

Precautions Before Starting Work Operations

Check Before Starting Engine

Check Machine Monitor

Check Coolant Level, Add Coolant

Check Oil Level in Engine Oil Pan, Add Oil

Check Water Separator, Drain Water

Check Air Cleaner

Electric Air Cleaner Clogging Sensor

Check Fuel Level, Add Fuel

Check Electric Wiring

Check Inflation Pressure of Tires

Check Condition of Window Washer Spray

Check Wiping Efficiency of Wiper

Check Horn

Check Defroster Function

Check Locks

Check Emergency Exit

Adjustments

Adjusting Seat

Removing or Installing Headrest

Adjusting Seat Belt

Adjusting Lever Stand

Adjusting Mirrors

Final Checks Before Starting Engine

Starting Engine

Normal Starting

Starting in Cold Weather

Automatic Warming-Up Operation

Operations and Checks After Starting Engine

Checks After Starting Engine

Breaking in the Machine

Normal Operation

Stopping Engine

Check After Stopping Engine

Moving the Machine (Directional, Speed), Stopping the Machine

Moving the Machine

Changing Gear Speed

Changing Direction

Automatic Shift

Stopping the Machine

Transmission Cut-Off Function

Adjusting Transmission Cut-Off Position

Canceling Transmission Cut-Off Position

Stopping When Transmission Cut-Off Is On

Turning

Emergency Steering (if equipped)

Emergency Steering Self-Check Function

Operation of Work Equipment

Work Equipment Lock Lever

Lift Arm Control lever

Bucket Control Lever

Work Possible Using Wheel Loader

Digging Operations

HANDLING TIRES

Precautions When Handling Tires

Tire Pressure

TRANSPORTATION

Transportation Procedure

Loading and Unloading Trailers

Loading Machine

Securing Machine

Unloading Machine

LIFTING MACHINE

Lifting Position

Lifting Procedure

COLD WEATHER OPERATION

Precautions for Low Temperature

Fuel and Lubricants

Coolant

Battery

Precautions After Completion of Work

After Cold Weather

LONG-TERM STORAGE

Before Storage

During Storage

After Storage

AUTOMATIC AIR CONDITIONER

Control Panel

Main Power Switch

Fan Switch

Air Conditioner Switch

Auto Switch

Temperature Switch

FRESH/RECIRC Selector Switch

Mode Selector Switch

Method of Operation

Cooling Operation

Heating Operation

Drying-Heating and Demisting Operation

When Not Using the Air Conditioner Regularly

Precautions When Using Air Conditioner

Inspection and Maintenance

Cool Box

KOMTRAX

Basic Precautions

TROUBLESHOOTING

When Machine Runs Out of Fuel

Towing the Machine

When Engine Can Be Used

When Engine Cannot Be Used

Releasing Parking Brake

Emergency Travel Operation

If Battery is Discharged

Precautions

Removal and Installation of Battery

Precautions for Charging Battery

Starting Engine With Booster Cables

Precautions When Connecting or Disconnecting Booster Cable

Connecting Booster Cable

Starting Engine

Disconnecting Booster Cable

Lowering Work Equipment When Engine Has Stopped

Other Troubleshooting

Electrical System

Chassis

Engine

GUIDES TO MAINTENANCE

Check Service Meter

Komatsu Genuine Replacement Parts

Komatsu Genuine Oils

Always Use Clean Washer Fluid

Always Use Clean Oil And Grease

Checking For Foreign Materials In Drained Oil And On Filters

Fuel Strainer

Welding Instructions

Do Not Drop Things Inside Machine

Dusty Work Sites

Avoid Mixing Oil

Locking Inspection Covers

Bleeding Air From Hydraulic Circuit

Precautions When Installing Hydraulic Hoses

Checks After Inspection and Maintenance

OUTLINES OF SERVICE

Handling Oil, Fuel, Coolant, And Performing Oil Clinic

WEAR PARTS

Wear Parts List

RECOMMENDED FUEL, COOLANT, AND LUBRICANT

Fuel, Coolant, and Lubricant Ambient Temperature Chart

Recommended Brands, Other Than Komatsu Genuine Oil

Biodiesel Usage

Biodiesel Recommendation for Komatsu Engines

Biodiesel Terminology

Certification and Standards

Warranty and Use of Biodiesel Fuel in Komatsu Engines

Requirements for Using Biodiesel Fuel in Komatsu Engines

Properties of Biodiesel

Komatsu Biodiesel Blend Specification for B5 to B20

Summary of Recommendations

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

Torque List

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

Safety Critical Parts List

MAINTENANCE SCHEDULE CHART

SERVICE PROCEDURE

Initial 250 Hours Service

Initial 1000 Hours Service

When Required

Every 50 Hours Service

Drain Water, Sediment from Fuel Tank

Every 100 Hours Service

Lubricate Rear Axle Pivot Pin

Check Oil Level in Hydraulic Tank, Add Oil

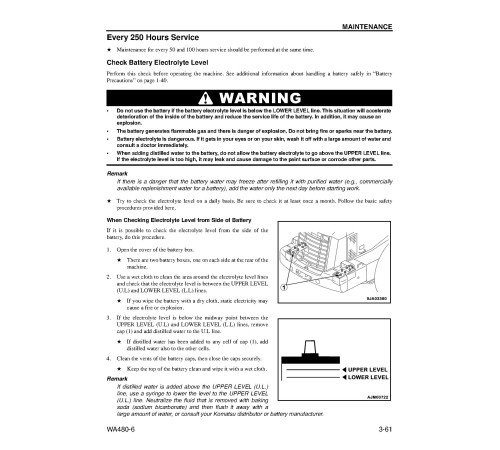

Every 250 Hours Service

Check Battery Electrolyte Level

Check Parking Brake

Check Alternator Belt Tension, Adjust

Check Air Conditioner Compressor Belt Tension, Adjust

Check for Loose Wheel Hub Nuts, Tighten

Clean Element in Air Conditioner Recirculation Filter

Check Function of Brake Accumulator

Lubricating

Every 500 Hours Service

Change Oil in Engine Oil Pan, Replace Engine Oil Filter Cartridge

Replace Fuel Prefilter Cartridge

Every 1000 Hours Service

Replace Fuel Main Filter Cartridge

Change Oil in Transmission Case, Replace Oil Filter Cartridge, Clean Strainer

Clean Transmission Case Breather

Lubricating

Replace Corrosion Resistor Cartridge

Check Engine Air Intake Piping Clamps for Looseness

Every 2000 Hours Service

Change Oil in Hydraulic Tank, Replace Hydraulic Filter Element

Replace Hydraulic Tank Breather Element

Change Axle Oil

Replace Element in Air Conditioner Recirculation Filter, Fresh Air Filter

Check Brake Disc Wear

Check Function of PPC Accumulator

Check Alternator

Check Engine Valve Clearance, Adjust

Check Starting Motor

Check Vibration Damper

Every 4000 Hours Service

Lubricating

Check Water Pump

Check Air Conditioner Compressor, Adjust

Check for Loose Engine High-Pressure Piping Clamps, Hardening of Rubber

Check for Missing Fuel Spray Prevention Cap, Hardening of Rubber

Every 8000 Hours Service

Replace High-Pressure Piping Clamps

Replace Fuel Spray Prevention Cap

SPECIFICATIONS

JOYSTICK STEERING SYSTEM

Structure and Function

Components

Shift UP, Shift DOWN Switches

Directional Selector Switch

Joystick Steering Lever

Joystick ON/OFF Switch

HI/LOW Selector Switch

Horn Switch

Console Tilt Lever

Console Fore-and-Aft Adjustment Lever

Joystick Pilot Lamp

Armrest Adjustment Lever

Steering with Joystick Lever or Steering Wheel

Precautions for Steering with Joystick

Operating the Joystick Steering System

Getting In and Out of Operator’s Cab

Adjustments

Adjusting Joystick Console

Adjusting Seat

LOAD METER

Outline of Load Meter

Principle of Load Meter Measurement

Conditions for Starting Measurement

Conditions for Completing Measurement

Conditions for Successful Measurement

Method of Calculation and Display

Points to Remember to Ensure High Accuracy

Calibration

When Measuring

Using Load Meter

Setting Addition Mode

Setting Subtraction Mode

Total Load Data Display

Clearing Total Load

Stopping Load Meter Calculation

Selecting Load Material Category Display

Calibrating With Empty Bucket

Calibrating with 1/2 Rated Load

Calibrating With Rated Load

Resetting Calibration

Method of Using Addition Mode

Method of Using Subtraction Mode

Printout from Load Meter

Selection of Printout Mode

TORQUE CONVERTER LOCK-UP

Components

Torque Converter Lock-Up Switch

Torque Converter Lock-Up Pilot Lamp

Shift Indicator

Character Display

Method of Operation

Warning/Limit Functions for Travel Speed

Travel Speed Warning Function

Travel Speed Limit Function

AM/FM RADIO CASSETTE STEREO SOUND SYSTEM

Sound System Components

Power Switch/Volume

Auto-Store/Preset Scan Button

Bass Control Knob

Treble Control Knob

Loudness Button

Time/Radio Display Selector Button

Tape Eject Button

Cassette Door

Fast-Forward, Rewind Buttons

Preset Buttons

Metal Tape Button

Manual Tuning Buttons

Seek Tuning Buttons

Band Selector Button

Method of Operation

Setting Preset Buttons

Using Auto-Preset

Using Manual Preset

Listening to Radio

Listening to Cassette Tape

Reversing the Tape

Precautions When Using

Handling Cassette Tape

MULTI-FUNCTION LEVER

Components

Work Equipment Lever

Kickdown Switch

Hold Switch

FNR Switch

Directional Selector Switch Actuation Switch

Directional Selector Pilot Lamp

Work Equipment Lock Switch

Using FNR Switch to Change Between Forward and Reverse

BUCKET AND TIRES

This manual will assist you in operating, and maintaining for your 4wd wheeled loader.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (USA):

WA480-6 (SN: A47001-)

Format: PDF, 426 pages

Language: English

Table of Contents:

FOREWORD

SAFETY INFORMATION

APPROVED AND NON-APPROVED USES

Approved Functions

Non-Approved Functions

VISIBILITY STANDARD

Visibility in Immediate Area

12-M Radius Visibility

Front/Rear, Left/Right Directions of Machine

Machine Serial Number/Product Identification Number (PIN)

Engine Serial Number, EPA Regulations

Position of Service Meter

Serial Numbers and Dealer Information

TABLE OF CONTENTS

SAFETY AND WARNING DECALS

Location of Safety Decals

Safety Labels

GENERAL SAFETY RULES AND PRECAUTIONS

General Safety Rules

General Safety at Job Site

Working on Loose Ground

Safety Features

Personal Protective Equipment

Keep Machine Clean

Fire and Explosion Prevention

Fire Caused by Fuel, Oil, Antifreeze, or Window Washer Fluid

Fire Caused by Accumulation of Flammable Material

Fire Coming from Electric Wiring

Fire Coming from Hydraulic Line

Windshield Washer Fluid

Action If Fire Occurs

Fire Extinguisher and First Aid Kit

Fire Prevention and Suppression

Fire Prevention Steps

Fixed Fire Detection System

Fixed Fire Suppression System

Fire Prevention Procedures

Precautions When Cleaning Cab Glass

Dust Hazards Precautions

Keep Operator's Cab Clean

Unauthorized Modifications

Leaving Operator’s Compartment

Mounting and Dismounting

Crush or Pinch Point Dangers

Inside Operator’s Compartment

Precautions When Using ROPS

Emergency Escape From Operator's Cab

PRECAUTIONS BEFORE STARTING OPERATIONS

Pre-Operational Checks

Starting Your Work Operations

Seat Belt Inspection

Work Site Hazards

Avoiding Dangerous Situations

Working Clearances

Operating on Snow or Icy Surfaces

Precautions in Cold Areas

Asbestos Hazard Alert

RULES FOR ROAD TRAVEL

Traveling in Reverse

Travel on Slopes

Parking the Machine

PRECAUTIONS DURING MAINTENANCE OPERATIONS

Warning Tags

Equipment Storage

Working Under the Machine

Using Drop Lamps

Keeping the Machine Clean

HANDLING TIRES

Precautions When Storing Tires

PERFORMING GENERAL MAINTENANCE PROCEDURES

Running the Engine During Maintenance

Proper Tools

Engine System High-Voltage

Welding, Grinding or Cutting

When Using Hammer

Refueling the Machine

Cooling System Precautions

Battery Precautions

Starting the Machine

High-Pressure Hoses

Safety Handling High-Pressure Hoses

Precaution For High Fuel Pressure

High Temperature Areas

Disposal of Waste Materials

Inflating Tires

Accumulator

Critical Parts

TRANSPORTING THE MACHINE

Loading and Unloading a Trailer

Loading Machine

TOWING THE MACHINE

GENERAL VIEW

General View Of Machine

General View of Controls and Gauges

Machine Monitor

Switch Panel

EXPLANATION OF COMPONENTS

Machine Monitor

Types of Warnings

Emergency Stop

Caution

Mistaken Operation

Inspection and Maintenance

Central Warning Lamp

Character Display Portion

Service Meter

Action Code Display

Failure Code Display

Filter, Oil Replacement Time Display

Emergency Stop Items

Brake Oil Pressure Caution Lamp

Engine Oil Pressure Caution Lamp

Battery Charge Circuit Caution Lamp

Steering Oil Pressure Caution Lamp (if equipped)

Caution Items

Meter Display Portion

Torque Converter Oil Temperature Gauge

Engine Coolant Temperature Gauge

Hydraulic Temperature Gauge

Fuel Gauge

Speedometer

Meter Display Pilot Lamp

OTHER FUNCTIONS OF MACHINE MONITOR

Overall Menu

Displaying Odometer

Resetting Filter, Oil Replacement Time

Entering Telephone Number

Selecting Language

Adjusting Monitor Brightness

Switching Travel Speed/Engine Speed Display

Switching Travel Speed/Engine Speed Display/Non-Display

SWITCHES AND CONTROLS

General View

Ignition Switch

Power Mode Selector Switch

Transmission Shift Mode Selector Switch

Transmission Cutoff Switch

Transmission Cutoff Set Switch

Lamp Switch

Turn Signal Lever

Dimmer Switch

Horn Button

Hazard Lamp Switch

Parking Brake Switch

Front Working Lamp Switch

Rear Working Lamp Switch

Machine Monitor Mode Selector Switch 1

Machine Monitor Mode Selector Switch 2

Kickdown Switch

Hold Switch

Front Wiper Switch

Rear Wiper Switch

Cigarette Lighter

Room Lamp Switch

Rear Heated Wire Glass Switch

ECSS Switch

Emergency Steering Switch (if equipped)

Cooling Fan Reverse Rotation Switch (If Equipped)

Cooling Fan Auto-Reverse Rotation Switch (If Equipped)

Conditions for Switching Fan Rotation

Torque Converter Lockup Switch (if equipped)

CONTROL LEVERS, PEDALS

General View

Gearshift Lever

Manual Shift

Automatic Shift

Directional Lever

Gearshift Lever Stopper

Work Equipment Lock Lever

Bucket Control Lever

Lift Arm Control Lever

Brake Pedals

Accelerator Pedal

SECURITY LOCKS AND SAFETY FEATURES

Steering Tilt Lock Lever

Frame Lock Bar

Cap with Lock

Fuel Tank Filler Port Cap

Back-Up Alarm

MACHINE FEATURES

Towing Pin

Grease Pump

Cab Door

Emergency Escape Right Door

Left Cab Door, Door Open Lock

Left Cab Door, Knob

Left Cab Door, Handle

Left Cab Sliding Window (Lock Release Knob)

Cab Wiper

ELECTRICAL

Power Outlet

Fuses

Fuse Capacity and Name of Circuit

Slow-Blow Fuse

WORK OPERATIONS

Walk-Around Check

Precautions Before Starting Work Operations

Check Before Starting Engine

Check Machine Monitor

Check Coolant Level, Add Coolant

Check Oil Level in Engine Oil Pan, Add Oil

Check Water Separator, Drain Water

Check Air Cleaner

Electric Air Cleaner Clogging Sensor

Check Fuel Level, Add Fuel

Check Electric Wiring

Check Inflation Pressure of Tires

Check Condition of Window Washer Spray

Check Wiping Efficiency of Wiper

Check Horn

Check Defroster Function

Check Locks

Check Emergency Exit

Adjustments

Adjusting Seat

Removing or Installing Headrest

Adjusting Seat Belt

Adjusting Lever Stand

Adjusting Mirrors

Final Checks Before Starting Engine

Starting Engine

Normal Starting

Starting in Cold Weather

Automatic Warming-Up Operation

Operations and Checks After Starting Engine

Checks After Starting Engine

Breaking in the Machine

Normal Operation

Stopping Engine

Check After Stopping Engine

Moving the Machine (Directional, Speed), Stopping the Machine

Moving the Machine

Changing Gear Speed

Changing Direction

Automatic Shift

Stopping the Machine

Transmission Cut-Off Function

Adjusting Transmission Cut-Off Position

Canceling Transmission Cut-Off Position

Stopping When Transmission Cut-Off Is On

Turning

Emergency Steering (if equipped)

Emergency Steering Self-Check Function

Operation of Work Equipment

Work Equipment Lock Lever

Lift Arm Control lever

Bucket Control Lever

Work Possible Using Wheel Loader

Digging Operations

HANDLING TIRES

Precautions When Handling Tires

Tire Pressure

TRANSPORTATION

Transportation Procedure

Loading and Unloading Trailers

Loading Machine

Securing Machine

Unloading Machine

LIFTING MACHINE

Lifting Position

Lifting Procedure

COLD WEATHER OPERATION

Precautions for Low Temperature

Fuel and Lubricants

Coolant

Battery

Precautions After Completion of Work

After Cold Weather

LONG-TERM STORAGE

Before Storage

During Storage

After Storage

AUTOMATIC AIR CONDITIONER

Control Panel

Main Power Switch

Fan Switch

Air Conditioner Switch

Auto Switch

Temperature Switch

FRESH/RECIRC Selector Switch

Mode Selector Switch

Method of Operation

Cooling Operation

Heating Operation

Drying-Heating and Demisting Operation

When Not Using the Air Conditioner Regularly

Precautions When Using Air Conditioner

Inspection and Maintenance

Cool Box

KOMTRAX

Basic Precautions

TROUBLESHOOTING

When Machine Runs Out of Fuel

Towing the Machine

When Engine Can Be Used

When Engine Cannot Be Used

Releasing Parking Brake

Emergency Travel Operation

If Battery is Discharged

Precautions

Removal and Installation of Battery

Precautions for Charging Battery

Starting Engine With Booster Cables

Precautions When Connecting or Disconnecting Booster Cable

Connecting Booster Cable

Starting Engine

Disconnecting Booster Cable

Lowering Work Equipment When Engine Has Stopped

Other Troubleshooting

Electrical System

Chassis

Engine

GUIDES TO MAINTENANCE

Check Service Meter

Komatsu Genuine Replacement Parts

Komatsu Genuine Oils

Always Use Clean Washer Fluid

Always Use Clean Oil And Grease

Checking For Foreign Materials In Drained Oil And On Filters

Fuel Strainer

Welding Instructions

Do Not Drop Things Inside Machine

Dusty Work Sites

Avoid Mixing Oil

Locking Inspection Covers

Bleeding Air From Hydraulic Circuit

Precautions When Installing Hydraulic Hoses

Checks After Inspection and Maintenance

OUTLINES OF SERVICE

Handling Oil, Fuel, Coolant, And Performing Oil Clinic

WEAR PARTS

Wear Parts List

RECOMMENDED FUEL, COOLANT, AND LUBRICANT

Fuel, Coolant, and Lubricant Ambient Temperature Chart

Recommended Brands, Other Than Komatsu Genuine Oil

Biodiesel Usage

Biodiesel Recommendation for Komatsu Engines

Biodiesel Terminology

Certification and Standards

Warranty and Use of Biodiesel Fuel in Komatsu Engines

Requirements for Using Biodiesel Fuel in Komatsu Engines

Properties of Biodiesel

Komatsu Biodiesel Blend Specification for B5 to B20

Summary of Recommendations

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

Torque List

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

Safety Critical Parts List

MAINTENANCE SCHEDULE CHART

SERVICE PROCEDURE

Initial 250 Hours Service

Initial 1000 Hours Service

When Required

Every 50 Hours Service

Drain Water, Sediment from Fuel Tank

Every 100 Hours Service

Lubricate Rear Axle Pivot Pin

Check Oil Level in Hydraulic Tank, Add Oil

Every 250 Hours Service

Check Battery Electrolyte Level

Check Parking Brake

Check Alternator Belt Tension, Adjust

Check Air Conditioner Compressor Belt Tension, Adjust

Check for Loose Wheel Hub Nuts, Tighten

Clean Element in Air Conditioner Recirculation Filter

Check Function of Brake Accumulator

Lubricating

Every 500 Hours Service

Change Oil in Engine Oil Pan, Replace Engine Oil Filter Cartridge

Replace Fuel Prefilter Cartridge

Every 1000 Hours Service

Replace Fuel Main Filter Cartridge

Change Oil in Transmission Case, Replace Oil Filter Cartridge, Clean Strainer

Clean Transmission Case Breather

Lubricating

Replace Corrosion Resistor Cartridge

Check Engine Air Intake Piping Clamps for Looseness

Every 2000 Hours Service

Change Oil in Hydraulic Tank, Replace Hydraulic Filter Element

Replace Hydraulic Tank Breather Element

Change Axle Oil

Replace Element in Air Conditioner Recirculation Filter, Fresh Air Filter

Check Brake Disc Wear

Check Function of PPC Accumulator

Check Alternator

Check Engine Valve Clearance, Adjust

Check Starting Motor

Check Vibration Damper

Every 4000 Hours Service

Lubricating

Check Water Pump

Check Air Conditioner Compressor, Adjust

Check for Loose Engine High-Pressure Piping Clamps, Hardening of Rubber

Check for Missing Fuel Spray Prevention Cap, Hardening of Rubber

Every 8000 Hours Service

Replace High-Pressure Piping Clamps

Replace Fuel Spray Prevention Cap

SPECIFICATIONS

JOYSTICK STEERING SYSTEM

Structure and Function

Components

Shift UP, Shift DOWN Switches

Directional Selector Switch

Joystick Steering Lever

Joystick ON/OFF Switch

HI/LOW Selector Switch

Horn Switch

Console Tilt Lever

Console Fore-and-Aft Adjustment Lever

Joystick Pilot Lamp

Armrest Adjustment Lever

Steering with Joystick Lever or Steering Wheel

Precautions for Steering with Joystick

Operating the Joystick Steering System

Getting In and Out of Operator’s Cab

Adjustments

Adjusting Joystick Console

Adjusting Seat

LOAD METER

Outline of Load Meter

Principle of Load Meter Measurement

Conditions for Starting Measurement

Conditions for Completing Measurement

Conditions for Successful Measurement

Method of Calculation and Display

Points to Remember to Ensure High Accuracy

Calibration

When Measuring

Using Load Meter

Setting Addition Mode

Setting Subtraction Mode

Total Load Data Display

Clearing Total Load

Stopping Load Meter Calculation

Selecting Load Material Category Display

Calibrating With Empty Bucket

Calibrating with 1/2 Rated Load

Calibrating With Rated Load

Resetting Calibration

Method of Using Addition Mode

Method of Using Subtraction Mode

Printout from Load Meter

Selection of Printout Mode

TORQUE CONVERTER LOCK-UP

Components

Torque Converter Lock-Up Switch

Torque Converter Lock-Up Pilot Lamp

Shift Indicator

Character Display

Method of Operation

Warning/Limit Functions for Travel Speed

Travel Speed Warning Function

Travel Speed Limit Function

AM/FM RADIO CASSETTE STEREO SOUND SYSTEM

Sound System Components

Power Switch/Volume

Auto-Store/Preset Scan Button

Bass Control Knob

Treble Control Knob

Loudness Button

Time/Radio Display Selector Button

Tape Eject Button

Cassette Door

Fast-Forward, Rewind Buttons

Preset Buttons

Metal Tape Button

Manual Tuning Buttons

Seek Tuning Buttons

Band Selector Button

Method of Operation

Setting Preset Buttons

Using Auto-Preset

Using Manual Preset

Listening to Radio

Listening to Cassette Tape

Reversing the Tape

Precautions When Using

Handling Cassette Tape

MULTI-FUNCTION LEVER

Components

Work Equipment Lever

Kickdown Switch

Hold Switch

FNR Switch

Directional Selector Switch Actuation Switch

Directional Selector Pilot Lamp

Work Equipment Lock Switch

Using FNR Switch to Change Between Forward and Reverse

BUCKET AND TIRES

General

Language

EnglishModel of Truck

WA480-6Region

USAType of Document

Operate and Maintenance manualType of Truck

4WD Wheeled LoaderReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.