Model

SEBM018225SKU

40797Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals:

[cummins-QSK60]

$25.00

Language

EnglishModel of Truck

WA1200-3, WA1200-3-ARegion

JapanType of Document

Workshop ManualType of Truck

4WD Wheeled LoaderIllustrated factory Workshop Manual for Komatsu 4WD Wheeled Loaders Models WA1200-3 and WA1200-3-A.

This manual will assist you in diagnosing, repairing, and adjusting for your 4wd wheeled loader.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

WA1200-3 (SN: 50001-)

WA1200-3-A (SN: 50001-)

Format: PDF, 2398 pages

Language: English

Table of Contents:

GENERAL

GENERAL ASSEMBLY DRAWING

SPECIFICATIONS

WEIGHT TABLE

LIST OF LUBRICANT AND WATER

STRUCTURE AND FUNCTION

OUTLINE

TADIATOR AND HYDRAULIC OIL COOLER

DAMPER

TORQUE CONVERTER AND TRANSMISSION PIPING

TORQUE CONVERTER

MAIN RELIEF VALVE AND TORQUE CONVERTER RELIEF VALVE

TORQUE CONVERTER REGULATOR VALVE

ECMV

TRANSMISSION

TRANSMISSION CONTROL VALVE

LUBRICATING OIL RELIEF VALVE

TRANSFER

TORQUE CONVERTER OIL COOLER

CENTER SUPPORT

AXLE

FINAL DRIVE

AXLE MOUNT

CENTER HINGE PIN

JACK-UP POINT

ARRANGEMENT OF STEERING EQUIPMENT

AJSS (ADVANCED JOYSTICK STEERING SYSTEM)

STEERING PUMP

SWITCH PUMP

SERVO VALVE

STEERING DEMAND VALVE

ROTARY VALVE

EPC VALVE

DIVERTER VALVE

ARRANGEMENT OF BRAKE EQUIPMENT

BRAKE VALVE

HARGE VALVE

ACCUMULATOR (FOR BRAKE)

SLACK ADJUSTER

BRAKE

PARKING BRAKE

PARKING BRAKE OIL CIRCUIT CHECK VALVE ASSEMBLY

ARRANGEMENT OF HYDRAULIC EQUIPMENT

WORK EQUIPMENT LEVER LINKAGE

HYDRAULIC TANK

WORK EQUIPMENT PUMP NO.1

WORK EQUIPMENT PUMP NO.2

WORK EQUIPMENT PUMP NEUTRAL CUT VALVE (NC VALVE)

PPC VALVE (PROPORTIONAL PRESSURE VALVE)

PPC RELIEF VALVE

ACCUMULATOR(FOR PPC VALVE)

MAIN CONTROL VALVE

WORK EQUIPMENT LINKAGE

OPERATION OF PROXIMITY SWITCH

AIR CONDITIONER

MACHINE MONITOR SYSTEM

MAIN MONITOR

CGC MONITOR

MULTI MONITOR

ALL-RANGE ELECTRONIC CONTROL AUTOMATIC TRANSMISSION (ATM) SYSTEM

MODULATED CLUTCH (MOD/C) CONTROL SYSTEM

WORK EQUIPMENT AND JOYSTICK STEERING CONTROL SYSTEM

WORK EQUIPMENT AND JOYSTICK STEERING CONTROLLER

ENGINE STARTING CIRCUIT

ENGINE STOPPING CIRCUIT

ETHER INJECTION CIRCUIT

ELECTRIC PARKING BRAKE CONTROL

PARKING BRAKE SOLENOID VALVE

EMERGENCY PARKING BRAKE RESET SOLENOID VALVE

KICK-DOWN SWITCH AND AUTO SHIFT/MANUAL SHIFT SELECTOR SWITCH

BATTERY DISCONNECTOR SWITCH

EMERGENCY ENGINE STOP SWITCH (FOR RIO TINTO)

HYDRAULIC OIL LEVEL CAUTION DISPLAY (FOR RIO TINTO)

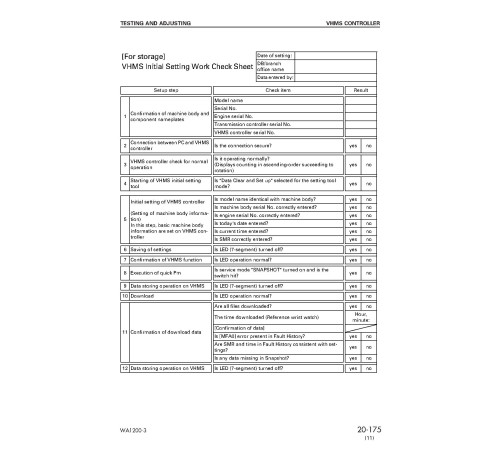

TESTING AND ADJUSTING

STANDARD VALUE TABLE

TESTING AND ADJUSTING

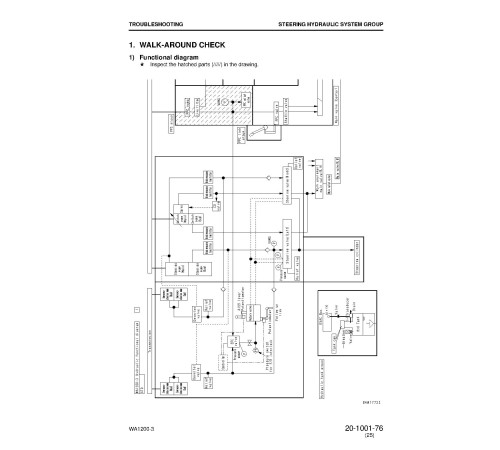

TROUBLESHOOTING

DISASSEMBLY AND ASSEMBLY

How to read this manual

Coating materials list

Special tool list

Sketches of special tools

Procedure for flushing work equipment and steering hydraulic circuit

Procedure for flushing brake hydraulic circuit

Bleeding air from piston pump

Bleeding air from work equipment circuit and steering circuit

Bleeding air from brake circuit

Removal and installation of DT connector pin

Removal and installation of HD connector pin

Repair procedure of HD connector pin harness

Removal and installation of engine assembly

Removal and installation of damper assembly

Disassembly and assembly of damper assembly

Removal and installation of radiator and hydraulic oil cooler assembly

Procedure for disassembly and assembly of MESABI oil cooler assembly

Disassembly and assembly of MESABI oil cooler assembly

Removal and installation of fuel cooler assembly

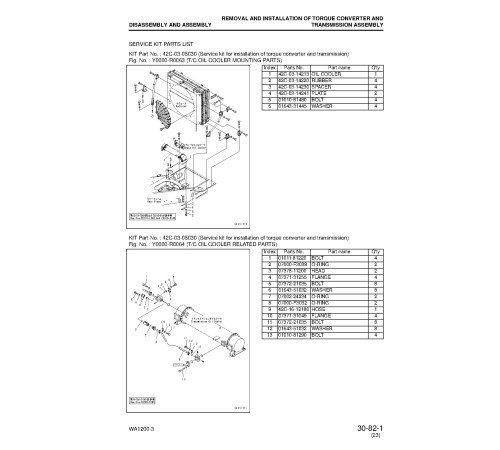

Removal and installation of torque converter and transmission oil cooler assembly

Removal and installation of bumper and fuel tank assembly

Removal and installation of hood assembly

Removal and installation of bulkhead assembly

Disassembly and assembly of ECMV

Removal and installation of torque converter and transmission assembly

Disconnection and connection of transmission assembly and torque converter assembly

Disconnection and connection of torque converter assembly and PTO • transfer assembly

Disassembly and assembly of torque converter assembly

Disassembly and assembly of modulated clutch assembly

Disassembly and assembly of PTO and transfer assembly

Disconnection and connection of transmission assembly and transfer • parking brake assembly

Disassembly and assembly of transmission assembly

Disassembly and assembly of transfer assembly

Disassembly and assembly of parking brake assembly

Removal and installation of parking brake assembly (from machine body)

Disassembly and assembly of drive shaft assembly

Removal and installation of front axle assembly

Removal and installation of front final drive assembly

Removal and installation of rear axle assembly

Disconnection and connection of differential assembly

Disassembly and assembly of differential assembly

Removal and installation of rear final drive assembly

Disassembly and assembly of final drive and brake assembly

Removal and installation of center support assembly

Disassembly and assembly of center support assembly

Removal and installation of steering demand valve assembly

Removal and installation of steering cylinder assembly

Removal and installation of steering pump, control pump and PPC pump assembly

Removal and installation of switching pump assembly

Removal and installation of emergency diverter valve assembly

Removal and installation of emergency steering pump assembly

Removal and installation of brake accumulator charge valve assembly

Removal and installation of brake oil cooler assembly

Removal and installation of brake oil tank assembly

Removal and installation of transmission, brake cooling and brake pump assembly

Disconnecting procedure for front frame and rear frame

Removal and installation of center hinge pin

Removal and installation of work equipment control valve assembly

Removal and installation of work equipment pump assembly (Right side)

Removal and installation of work equipment pump assembly (Left side)

Removal and installation of hydraulic tank and filter case assembly

Removal and installation of bucket cylinder assembly

Removal and installation of lift cylinder assembly

Disassembly and assembly of hydraulic cylinder assembly

Removal and installation of work equipment assembly

Run-in procedure for bucket pin

Run-in procedure for lift arm pin

Removal and installation of air conditioner unit assembly

Removal and installation of operator`s cab and floor assembly1

Removal and installation of operator`s cab assembly

Disassembly and assembly of operator`s seat assembly

Removal and installation of controller assemblies

SERVICE KIT PARTS LIST

MAINTENANCE STANDARD

ENGINE MOUNT

TRANSMISSION MOUNT

RADIATOR AND OIL COOLER

DAMPER

TORQUE CONVERTER, TRANSMISSION, BRAKE COOLING AND BRAKE PUMP

INPUT TRANSFER. PTO

MODULATED CLUTCH

TORQUE CONVERTER

TRANSMISSION

TRANSFER

MAINRELIEF, TORQUE CONVERTER RELIEF VALVE

TORQUE CONVERTER REGULATOR VALVE

BY-PASS FILL VALVE

BY-PASS FILL VALVE AND BY-PASS DRAIN VALVE

ECMV

LUBRICATIONG OIL RELIEF VALVE

DRIVE SHAFT

CENTER SUPPORT

DIFFERENTIAL

FINAL DRIVE

AXLE MOUNT

CENTER HINGE PIN

STEERING PUMP

SWITCH PUMP

STEERING DEMAND VALVE

DIVERTER VALVE

STEERING CYLINDER MOUNT

EMERGENCY STEERING PUMP

BRAKE VALVE

SLACK ADJUSTER

BRAKE

PARDING BRAKE

WORK EQUIPMENT PUMP NO.1

WORK EQUIPMENT PUMP NO.2

PPC VALVE

PPC RELIEF VALVE

PUMP CONTROL RELIEF VALVE

MAIN CONTROL VALVE

HYDRAULIC CYLINDER

BUCKET POSITIONER AND REMOTE POSITIONER

BUCKET LINKAGE

OTHERS

TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM

BRAKE CIRCUIT DIAGRAM

WORK EUIPMENT HYDRAULIC CIRCUIT DIAGRAM (1/2) Serial No. : 50001 - 50084

WORK

This manual will assist you in diagnosing, repairing, and adjusting for your 4wd wheeled loader.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Japan):

WA1200-3 (SN: 50001-)

WA1200-3-A (SN: 50001-)

Format: PDF, 2398 pages

Language: English

Table of Contents:

GENERAL

GENERAL ASSEMBLY DRAWING

SPECIFICATIONS

WEIGHT TABLE

LIST OF LUBRICANT AND WATER

STRUCTURE AND FUNCTION

OUTLINE

TADIATOR AND HYDRAULIC OIL COOLER

DAMPER

TORQUE CONVERTER AND TRANSMISSION PIPING

TORQUE CONVERTER

MAIN RELIEF VALVE AND TORQUE CONVERTER RELIEF VALVE

TORQUE CONVERTER REGULATOR VALVE

ECMV

TRANSMISSION

TRANSMISSION CONTROL VALVE

LUBRICATING OIL RELIEF VALVE

TRANSFER

TORQUE CONVERTER OIL COOLER

CENTER SUPPORT

AXLE

FINAL DRIVE

AXLE MOUNT

CENTER HINGE PIN

JACK-UP POINT

ARRANGEMENT OF STEERING EQUIPMENT

AJSS (ADVANCED JOYSTICK STEERING SYSTEM)

STEERING PUMP

SWITCH PUMP

SERVO VALVE

STEERING DEMAND VALVE

ROTARY VALVE

EPC VALVE

DIVERTER VALVE

ARRANGEMENT OF BRAKE EQUIPMENT

BRAKE VALVE

HARGE VALVE

ACCUMULATOR (FOR BRAKE)

SLACK ADJUSTER

BRAKE

PARKING BRAKE

PARKING BRAKE OIL CIRCUIT CHECK VALVE ASSEMBLY

ARRANGEMENT OF HYDRAULIC EQUIPMENT

WORK EQUIPMENT LEVER LINKAGE

HYDRAULIC TANK

WORK EQUIPMENT PUMP NO.1

WORK EQUIPMENT PUMP NO.2

WORK EQUIPMENT PUMP NEUTRAL CUT VALVE (NC VALVE)

PPC VALVE (PROPORTIONAL PRESSURE VALVE)

PPC RELIEF VALVE

ACCUMULATOR(FOR PPC VALVE)

MAIN CONTROL VALVE

WORK EQUIPMENT LINKAGE

OPERATION OF PROXIMITY SWITCH

AIR CONDITIONER

MACHINE MONITOR SYSTEM

MAIN MONITOR

CGC MONITOR

MULTI MONITOR

ALL-RANGE ELECTRONIC CONTROL AUTOMATIC TRANSMISSION (ATM) SYSTEM

MODULATED CLUTCH (MOD/C) CONTROL SYSTEM

WORK EQUIPMENT AND JOYSTICK STEERING CONTROL SYSTEM

WORK EQUIPMENT AND JOYSTICK STEERING CONTROLLER

ENGINE STARTING CIRCUIT

ENGINE STOPPING CIRCUIT

ETHER INJECTION CIRCUIT

ELECTRIC PARKING BRAKE CONTROL

PARKING BRAKE SOLENOID VALVE

EMERGENCY PARKING BRAKE RESET SOLENOID VALVE

KICK-DOWN SWITCH AND AUTO SHIFT/MANUAL SHIFT SELECTOR SWITCH

BATTERY DISCONNECTOR SWITCH

EMERGENCY ENGINE STOP SWITCH (FOR RIO TINTO)

HYDRAULIC OIL LEVEL CAUTION DISPLAY (FOR RIO TINTO)

TESTING AND ADJUSTING

STANDARD VALUE TABLE

TESTING AND ADJUSTING

TROUBLESHOOTING

DISASSEMBLY AND ASSEMBLY

How to read this manual

Coating materials list

Special tool list

Sketches of special tools

Procedure for flushing work equipment and steering hydraulic circuit

Procedure for flushing brake hydraulic circuit

Bleeding air from piston pump

Bleeding air from work equipment circuit and steering circuit

Bleeding air from brake circuit

Removal and installation of DT connector pin

Removal and installation of HD connector pin

Repair procedure of HD connector pin harness

Removal and installation of engine assembly

Removal and installation of damper assembly

Disassembly and assembly of damper assembly

Removal and installation of radiator and hydraulic oil cooler assembly

Procedure for disassembly and assembly of MESABI oil cooler assembly

Disassembly and assembly of MESABI oil cooler assembly

Removal and installation of fuel cooler assembly

Removal and installation of torque converter and transmission oil cooler assembly

Removal and installation of bumper and fuel tank assembly

Removal and installation of hood assembly

Removal and installation of bulkhead assembly

Disassembly and assembly of ECMV

Removal and installation of torque converter and transmission assembly

Disconnection and connection of transmission assembly and torque converter assembly

Disconnection and connection of torque converter assembly and PTO • transfer assembly

Disassembly and assembly of torque converter assembly

Disassembly and assembly of modulated clutch assembly

Disassembly and assembly of PTO and transfer assembly

Disconnection and connection of transmission assembly and transfer • parking brake assembly

Disassembly and assembly of transmission assembly

Disassembly and assembly of transfer assembly

Disassembly and assembly of parking brake assembly

Removal and installation of parking brake assembly (from machine body)

Disassembly and assembly of drive shaft assembly

Removal and installation of front axle assembly

Removal and installation of front final drive assembly

Removal and installation of rear axle assembly

Disconnection and connection of differential assembly

Disassembly and assembly of differential assembly

Removal and installation of rear final drive assembly

Disassembly and assembly of final drive and brake assembly

Removal and installation of center support assembly

Disassembly and assembly of center support assembly

Removal and installation of steering demand valve assembly

Removal and installation of steering cylinder assembly

Removal and installation of steering pump, control pump and PPC pump assembly

Removal and installation of switching pump assembly

Removal and installation of emergency diverter valve assembly

Removal and installation of emergency steering pump assembly

Removal and installation of brake accumulator charge valve assembly

Removal and installation of brake oil cooler assembly

Removal and installation of brake oil tank assembly

Removal and installation of transmission, brake cooling and brake pump assembly

Disconnecting procedure for front frame and rear frame

Removal and installation of center hinge pin

Removal and installation of work equipment control valve assembly

Removal and installation of work equipment pump assembly (Right side)

Removal and installation of work equipment pump assembly (Left side)

Removal and installation of hydraulic tank and filter case assembly

Removal and installation of bucket cylinder assembly

Removal and installation of lift cylinder assembly

Disassembly and assembly of hydraulic cylinder assembly

Removal and installation of work equipment assembly

Run-in procedure for bucket pin

Run-in procedure for lift arm pin

Removal and installation of air conditioner unit assembly

Removal and installation of operator`s cab and floor assembly1

Removal and installation of operator`s cab assembly

Disassembly and assembly of operator`s seat assembly

Removal and installation of controller assemblies

SERVICE KIT PARTS LIST

MAINTENANCE STANDARD

ENGINE MOUNT

TRANSMISSION MOUNT

RADIATOR AND OIL COOLER

DAMPER

TORQUE CONVERTER, TRANSMISSION, BRAKE COOLING AND BRAKE PUMP

INPUT TRANSFER. PTO

MODULATED CLUTCH

TORQUE CONVERTER

TRANSMISSION

TRANSFER

MAINRELIEF, TORQUE CONVERTER RELIEF VALVE

TORQUE CONVERTER REGULATOR VALVE

BY-PASS FILL VALVE

BY-PASS FILL VALVE AND BY-PASS DRAIN VALVE

ECMV

LUBRICATIONG OIL RELIEF VALVE

DRIVE SHAFT

CENTER SUPPORT

DIFFERENTIAL

FINAL DRIVE

AXLE MOUNT

CENTER HINGE PIN

STEERING PUMP

SWITCH PUMP

STEERING DEMAND VALVE

DIVERTER VALVE

STEERING CYLINDER MOUNT

EMERGENCY STEERING PUMP

BRAKE VALVE

SLACK ADJUSTER

BRAKE

PARDING BRAKE

WORK EQUIPMENT PUMP NO.1

WORK EQUIPMENT PUMP NO.2

PPC VALVE

PPC RELIEF VALVE

PUMP CONTROL RELIEF VALVE

MAIN CONTROL VALVE

HYDRAULIC CYLINDER

BUCKET POSITIONER AND REMOTE POSITIONER

BUCKET LINKAGE

OTHERS

TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM

BRAKE CIRCUIT DIAGRAM

WORK EUIPMENT HYDRAULIC CIRCUIT DIAGRAM (1/2) Serial No. : 50001 - 50084

WORK

General

Language

EnglishModel of Truck

WA1200-3, WA1200-3-ARegion

JapanType of Document

Workshop ManualType of Truck

4WD Wheeled LoaderReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.