Model

VEBM470104SKU

40977Brand

KomatsuAvailability:

Ready for Instant DownloadThis manual does not contain engine information. Depending on the engine used, see the manuals: Cummins 6CTA8.3:

[cummins-6CTA8.3]

$25.00

Language

EnglishModel of Truck

WA420-3Region

GermanyType of Document

Workshop ManualType of Truck

4WD Wheeled LoaderIllustrated factory Workshop Manual for Komatsu 4WD Wheeled Loaders Models WA420-3.

This manual will assist you in diagnosing, repairing, and adjusting for your 4wd wheeled loader.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

WA420-3 (SN: H30051-)

Format: PDF, 970 pages

Language: English

Table of Contents:

General

Up to SN WA420H30296

Dimensions and weights

Specifications

Weight table

SN WA420H30297 and up

Dimensions and weights

Specifications

Weight table

List of lubricant and water

Outlines of service

General view of controls and gauges

Torque list

Structure and function

Power train

Power train system

Torque converter, transmission piping

Transmission hydraulic system diagram

Transmission hydraulic circuit diagram

Torque converter

Transmission

Clutch

Transmission control valve

Transmission solenoid valve

Pilot reducing valve

Main relief valve

Torque converter outlet port valve

Priority valve

Transmission oil pressure system diagram

H-L selector valve and range selector valve

Emergency manual spool

Electronic control modulation valve

Pilot oil filter

Accumulator valve

Flow valve

Check valve

Drive shaft

Axle

Differential

Final drive

Axle mount, center hinge pin

Steering piping

Steering column, orbit roll

Hydraulic circuit diagram for steering

Orbit-roll valve

Steering demand valve

Overload relief valve

Steering relief valve

Operation of demand valve

Emergency steering

Brake piping

Brake circuit diagram

Brake valve

Charge valve

Accumulator for system brake

Slack adjuster

Brake circuit diagram

Brake valve (dual circuit)

Brake valve (single circuit)

Brake pressure regulating valve

Accumulator (for brake)

Accumulator for PPC valve

Brake accumulator unit

Brake

Parking brake control

Parking brake

Parking brake valve

Hydraulic piping

Work equipment hydraulic circuit diagram

Work equipment lever linkage

Hydraulic tank

PPC valve

PPC relief valve

Accumulator for PPC valve

Main control valve (up to H30296)

Relief valve (up to H30296

Safety valve (with suction)

Suction valve

Main control valve (H30297 and up)

Safety valve with suction (H30297 and up)

Anticavitation valve (H30297 and up)

Safety valve (H30297 and up)

Hydraulic safety system

Hydraulic safety system location (up to H30431)

Hydraulic safety valve (up to H30431)

Work equipment linkage

Bucket

Bucket positioner and boom kick-out

Machine monitor system

Main monitor

Maintenance monitor

Transmission auto-shift control system

Transmission controller

E.C.S.S.

Sensors

Engine start circuit

Ether start

Electric transmission control

Combination switch

Kick-down, hold switch

Transmission electric circuit diagram

Transmission cut-off switch

Transmission cut-off function

Electric parking brake control

Air-conditioner

Wiring diagrams

Testing and adjusting

Standard value table for engine

Standard value table for chassis

Test certificate

Standard value table for electrical parts

Tools for testing, adjusting and troubleshooting

Adjusting valve clearance

Measuring compression pressure

Measuring blow-by pressure

Testing and adjusting fuel injection timing

Mesuring exhaust color

Measuring intake air pressure (boost pressure)

Measuring engine oil pressure

Testing the fan belt tension

Measuring accelerator pedal

Basic adjustment of accelerator pedal

Measuring operating force, travel of speed lever

Measuring stall speed

Measuring torque converter, transmission, parking brake oil pressure

Method of operating emergency manual spool

Measuring clearance between tyre and wheel

Measuring operating force of steering wheel

Measuring steering oil pressure

Measuring operating force, travel of brake pedal

Measuring brake performance

Testing brake oil pressure

Measuring brake disc wear

Bleeding air from brake system

Measuring parking brake performance

Method of manual release of parking brake

Testing wear of parking brake disc

Measuring work equipment control lever

Measuring PPC valve pressure

Measuring work equipment

Testing and adjusting bucket positioner

Testing and adjusting boom kick-out

Adjusting main monitor (speedometer modul)

Checking for abnormality in fuel level sensor

Troubleshooting

Points to remember when troubleshooting

Sequence of events in troubleshooting

Precautions when carrying out maintenance

Handling connectors

Checks before troubleshooting

Method of using troubleshooting charts

Connector types and mounting locations, connector pin arrangement diagram

Connection table for connector pin numbers

Troubleshooting of engine system (S mode)

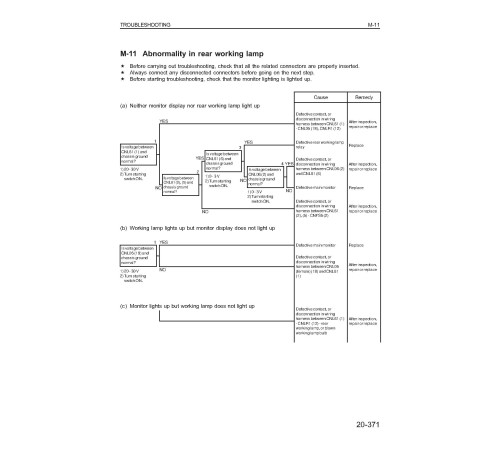

Troubleshooting of main monitor system (M mode)

Troubleshooting of maintenance monitor system (K mode)

Troubleshooting of electrical system (E mode)

Troubleshooting of transmission controller system (A mode)

Troubleshooting of hydraulic and mechanical system (Chassis related) (T mode)

Troubleshooting of ECSS (Electronically Controlled Suspension System) (D mode)

Disassembly and assembly

Method of using manual

Precautions when carrying out operation

Special tool list

Starting motor

Alternator

Engine oil cooler

Fuel injection pump

Water pump

Turbocharger

Thermostat

Cylinder head

Torque converter charging pump

Torque converter, transmission

Torque converter

Tranmission

Transmission clutch pack

Parking brake

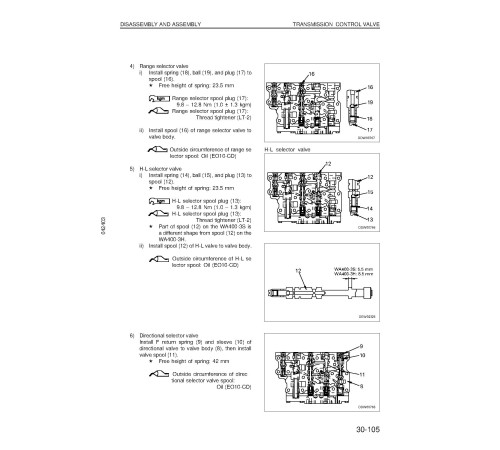

Transmission control valve

Transmission accumulator valve

Drive shaft

Front axle

Rear axle

Front differential

Rear differential

Differential

Final drive

Center hinge pin

Steering, orbit roll

Steering valve

Steering, switch pump

Steering cylinder

Brake valve

Right brake valve (tandem)

Left brake valve (single)

Slack adjuster

Brake

Parking brake disc

Hydraulic tank

Work equipment, PPC pump

PPC valve

Main control valve

Bucket cylinder

Boom cylinder

Hydraulic cylinder

Work equipment

Counterweight

Fuel tank

Cab

Main monitor

Maintenance monitor

Air conditioner unit

Air conditioner condenser

Dry receiver

Air conditioner compressor

Maintenance standard

Engine mount, transmission mount

Torque converter

Transmission

Transmission control valve

Drive shaft

Diffential

Final drive

Axle mount

Steerig column, orbit roll

Steering valve

Steering cylinder mount

Slack adjuster

Brake valve

Brake

Parking brake

Torque converter, transmission pump

Steering, switch pump

Hydraulic, PPC pump

PPC valve

Cut-off valve

Main control valve

Boom cylinder

Bucket cylinder

Center hinge pin

Work equipment linkage

Bucket

Bucket positioner and boom kick-out

This manual will assist you in diagnosing, repairing, and adjusting for your 4wd wheeled loader.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models (Germany):

WA420-3 (SN: H30051-)

Format: PDF, 970 pages

Language: English

Table of Contents:

General

Up to SN WA420H30296

Dimensions and weights

Specifications

Weight table

SN WA420H30297 and up

Dimensions and weights

Specifications

Weight table

List of lubricant and water

Outlines of service

General view of controls and gauges

Torque list

Structure and function

Power train

Power train system

Torque converter, transmission piping

Transmission hydraulic system diagram

Transmission hydraulic circuit diagram

Torque converter

Transmission

Clutch

Transmission control valve

Transmission solenoid valve

Pilot reducing valve

Main relief valve

Torque converter outlet port valve

Priority valve

Transmission oil pressure system diagram

H-L selector valve and range selector valve

Emergency manual spool

Electronic control modulation valve

Pilot oil filter

Accumulator valve

Flow valve

Check valve

Drive shaft

Axle

Differential

Final drive

Axle mount, center hinge pin

Steering piping

Steering column, orbit roll

Hydraulic circuit diagram for steering

Orbit-roll valve

Steering demand valve

Overload relief valve

Steering relief valve

Operation of demand valve

Emergency steering

Brake piping

Brake circuit diagram

Brake valve

Charge valve

Accumulator for system brake

Slack adjuster

Brake circuit diagram

Brake valve (dual circuit)

Brake valve (single circuit)

Brake pressure regulating valve

Accumulator (for brake)

Accumulator for PPC valve

Brake accumulator unit

Brake

Parking brake control

Parking brake

Parking brake valve

Hydraulic piping

Work equipment hydraulic circuit diagram

Work equipment lever linkage

Hydraulic tank

PPC valve

PPC relief valve

Accumulator for PPC valve

Main control valve (up to H30296)

Relief valve (up to H30296

Safety valve (with suction)

Suction valve

Main control valve (H30297 and up)

Safety valve with suction (H30297 and up)

Anticavitation valve (H30297 and up)

Safety valve (H30297 and up)

Hydraulic safety system

Hydraulic safety system location (up to H30431)

Hydraulic safety valve (up to H30431)

Work equipment linkage

Bucket

Bucket positioner and boom kick-out

Machine monitor system

Main monitor

Maintenance monitor

Transmission auto-shift control system

Transmission controller

E.C.S.S.

Sensors

Engine start circuit

Ether start

Electric transmission control

Combination switch

Kick-down, hold switch

Transmission electric circuit diagram

Transmission cut-off switch

Transmission cut-off function

Electric parking brake control

Air-conditioner

Wiring diagrams

Testing and adjusting

Standard value table for engine

Standard value table for chassis

Test certificate

Standard value table for electrical parts

Tools for testing, adjusting and troubleshooting

Adjusting valve clearance

Measuring compression pressure

Measuring blow-by pressure

Testing and adjusting fuel injection timing

Mesuring exhaust color

Measuring intake air pressure (boost pressure)

Measuring engine oil pressure

Testing the fan belt tension

Measuring accelerator pedal

Basic adjustment of accelerator pedal

Measuring operating force, travel of speed lever

Measuring stall speed

Measuring torque converter, transmission, parking brake oil pressure

Method of operating emergency manual spool

Measuring clearance between tyre and wheel

Measuring operating force of steering wheel

Measuring steering oil pressure

Measuring operating force, travel of brake pedal

Measuring brake performance

Testing brake oil pressure

Measuring brake disc wear

Bleeding air from brake system

Measuring parking brake performance

Method of manual release of parking brake

Testing wear of parking brake disc

Measuring work equipment control lever

Measuring PPC valve pressure

Measuring work equipment

Testing and adjusting bucket positioner

Testing and adjusting boom kick-out

Adjusting main monitor (speedometer modul)

Checking for abnormality in fuel level sensor

Troubleshooting

Points to remember when troubleshooting

Sequence of events in troubleshooting

Precautions when carrying out maintenance

Handling connectors

Checks before troubleshooting

Method of using troubleshooting charts

Connector types and mounting locations, connector pin arrangement diagram

Connection table for connector pin numbers

Troubleshooting of engine system (S mode)

Troubleshooting of main monitor system (M mode)

Troubleshooting of maintenance monitor system (K mode)

Troubleshooting of electrical system (E mode)

Troubleshooting of transmission controller system (A mode)

Troubleshooting of hydraulic and mechanical system (Chassis related) (T mode)

Troubleshooting of ECSS (Electronically Controlled Suspension System) (D mode)

Disassembly and assembly

Method of using manual

Precautions when carrying out operation

Special tool list

Starting motor

Alternator

Engine oil cooler

Fuel injection pump

Water pump

Turbocharger

Thermostat

Cylinder head

Torque converter charging pump

Torque converter, transmission

Torque converter

Tranmission

Transmission clutch pack

Parking brake

Transmission control valve

Transmission accumulator valve

Drive shaft

Front axle

Rear axle

Front differential

Rear differential

Differential

Final drive

Center hinge pin

Steering, orbit roll

Steering valve

Steering, switch pump

Steering cylinder

Brake valve

Right brake valve (tandem)

Left brake valve (single)

Slack adjuster

Brake

Parking brake disc

Hydraulic tank

Work equipment, PPC pump

PPC valve

Main control valve

Bucket cylinder

Boom cylinder

Hydraulic cylinder

Work equipment

Counterweight

Fuel tank

Cab

Main monitor

Maintenance monitor

Air conditioner unit

Air conditioner condenser

Dry receiver

Air conditioner compressor

Maintenance standard

Engine mount, transmission mount

Torque converter

Transmission

Transmission control valve

Drive shaft

Diffential

Final drive

Axle mount

Steerig column, orbit roll

Steering valve

Steering cylinder mount

Slack adjuster

Brake valve

Brake

Parking brake

Torque converter, transmission pump

Steering, switch pump

Hydraulic, PPC pump

PPC valve

Cut-off valve

Main control valve

Boom cylinder

Bucket cylinder

Center hinge pin

Work equipment linkage

Bucket

Bucket positioner and boom kick-out

General

Language

EnglishModel of Truck

WA420-3Region

GermanyType of Document

Workshop ManualType of Truck

4WD Wheeled LoaderReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.