$25.00

Language

EnglishModel of Truck

FB20HB-11, FB25HB-11Region

WorldWideType of Document

Workshop ManualType of Truck

Forklift TruckIllustrated factory set of Workshop Manuals for Komatsu BE30 Hybrid Forklift Trucks Models FB20HB-11 and FB25HB-11.

This manuals will assist you in diagnosing, repairing, and adjusting for your forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

BE30 Hybrid FB20HB-11 (SN: M254-817001-)

BE30 Hybrid FB25HB-11 (SN: M254-817001-)

The manual comprises two Workshop Manuals

1. Workshop Manual (BBB11E1-02_SM)

Format: PDF, 422 pages

Language: English

Table of Contents:

INDEX

Foreword

PRECAUTIONS WHEN PERFORMING THE SERVICE WORK

description of the symbols

GENERAL AND SPECIFICATIONS

Outside view and specifications

SAFETY ITEMS FOR MAINTENANCE

standard tightening torque for bolts

STANDARD TIGhTENING TORQUE FOR PIPE JOINTS

How to use LOCTITE

conversion table

PERIODIC REPLACEMENT OF CONSUMABLE PARTS

TESTING AND ADJUSTING

Service data (1.0 - 1.75 tON models)

Service data (2.0 - 3.0 tON models)

How to operate lift interrupt function

How to reset electrolyte level indicator function

How to start hour meter

Operation of meter panel

Adjusting lowering speed of fork

(PROPORTIONAL SOLENOID VALVE)

Battery

Fuse

Transfer case

Stationary charger

Brake pedal

Wheel brake

Adjusting parking brake lever

Hydraulic tank

Rear axle (Steering axle)

Mast (1.0 - 1.75 ton models)

Mast (2.0 - 3.0 ton models)

fork carriage (1.0 - 1.75 ton models)

fork carriage (2.0 - 3.0 ton models)

Measuring hydraulic drift of hydraulic cylinder and hydraulic drift of leaning forward

Bleeding air

Removal and installation

Arrangement of units

Weight of each unit (1.0 - 1.75 ton models)

Weight of each unit (2.0 - 3.0 ton models)

General disassembly and assembly drawing

Mast

Lift cylinder

Power train (Front axle + Transfer + Drive motor)

Rear axle

Battery

EPS actuator

Steering gear box

Hydraulic pump + Pump motor

Disassembly and assembly

Transfer (1.0 - 1.75 ton models)

Transfer (2.0 - 2.5 ton models)

Transfer (3.0 ton model)

Differential (1.0 - 1.75 ton models)

Differential (2.0 - 3.0 ton models)

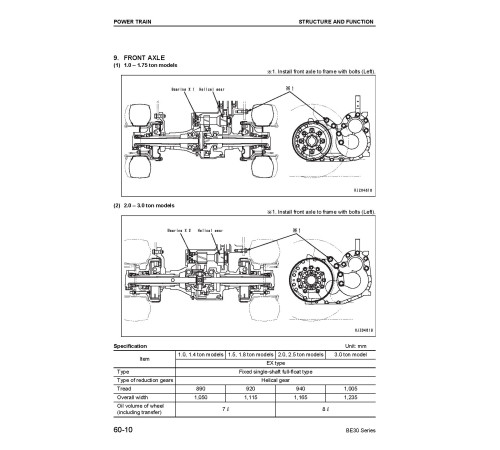

Front axle (1.0 - 1.75 ton models)

Front axle (2.0 - 2.5 ton models)

Front axle (3.0 ton model)

Brake master cylinder

Damping cylinder

Wheel brake (1.0 - 1.75 ton models)

Wheel brake (2.0 - 2.5 ton models)

Steering gear box

EPS actuator

Wheel brake (3.0 ton model)

Rear axle (1.0 - 1.75 ton models)

Rear axle (2.0 - 3.0 ton models)

Lift cylinder

tilt cylinder (6 /12 )

Hydraulic pump

Control valve (Proportional solenoid valve spec.)

Control valve (Manual valve spec.)

pump motor

Drive motor

MAINTENANCE STANDARD

Transfer

Differential (1.0 - 1.75 ton models)

Differential (2.0 - 3.0 ton models)

Front axle (1.0 - 1.75 ton models)

Front axle (2.0 - 2.5 ton models)

Front axle (3.0 ton model)

Brake master cylinder

Damping cylinder

Wheel brake (1.0 - 1.75 ton models)

Wheel brake (2.0 - 2.5 ton models)

Wheel brake (3.0 ton model)

Rear axle (1.0 - 1.75 ton models)

Rear axle (2.0 - 3.0 ton models)

Lift cylinder

Tilt cylinder

Control valve (Proportional solenoid valve spec.)

Control valve (Manual valve spec.)

Hydraulic pump

Mast, fork carriage, and fork (1.0 - 1.75 ton models)

Mast, fork carriage, and fork (2.0 - 3.0 ton models)

Drive motor (1.0 - 2.5 ton models)

Drive motor (3.0 ton model)

Pump motor (1.0 - 1.75 ton models)

Pump motor (2.0 - 3.0 ton models)

Power steering motor

Structure and function

Power train

Travel system

Braking device

Steering system

Hydraulic system

Hydraulic control valve (Proportional solenoid valve spec.)

Work equipment

Power connector for optional devices

Control unit

Operating device (Meter panel, switches, etc.)

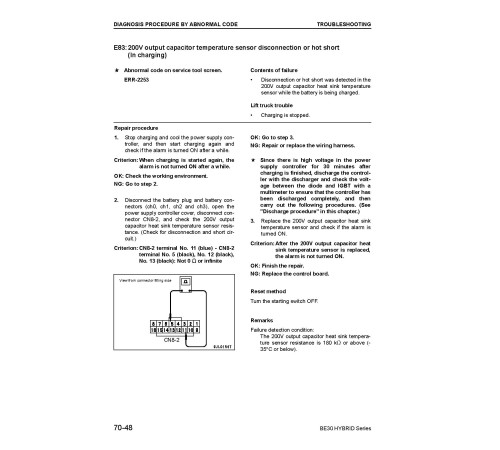

TROUBLESHOOTING

Controller

Main controller

Drive motor

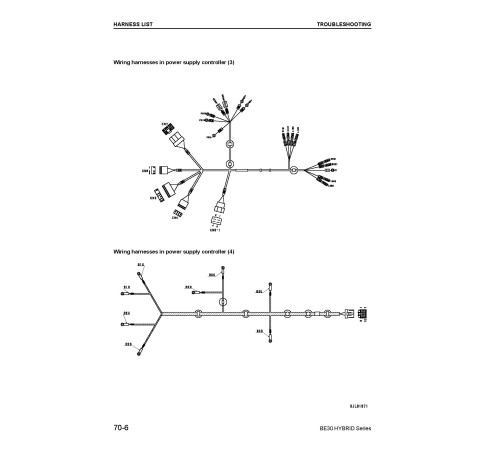

Electric circuit diagram (A3)

Electric circuit diagram (A3)

Electric circuit diagram (A3)

Electric circuit diagram (A3)

Electric circuit diagram (A3)

Sub controller

Troubleshooting

SELF-DIAGNOSIS LOGIC TABLE (1.0 - 3.0 ton models)

CHARGER

Yearly inspection criteria

Starting motor and pump motor

Battery

Controller

Power train

Travel system

Steering system

Brake system

Cargo handling system

2. Workshop Manual: SUPPLEMENT for BE30 Hybrid Series (BHB11E1-02_SM)

Format: PDF, 167 pages

Language: English

Table of Contents:

FOREWORD

GENERAL AND SPECIFICATIONS (Use along with Shop Manual BBB11E1-02.)

TESTING AND ADJUSTMENT (Use along with Shop Manual BBB11E1-02.)

REMOVAL AND INSTALLATION (Use along with Shop Manual BBB11E1-02.)

DISASSEMBLY AND ASSEMBLY (See Shop Manual BBB11E1-02.)

MAINTENANCE STANDARD (See Shop Manual BBB11E1-02.)

STRUCTURE AND FUNCTION (See Shop Manual BBB11E1-02.)

TROUBLESHOOTING (Use along with Shop Manual BBB11E1-02.)

YEARLY INSPECTION CRITERIA

CONVERSION TABLE

This manuals will assist you in diagnosing, repairing, and adjusting for your forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

BE30 Hybrid FB20HB-11 (SN: M254-817001-)

BE30 Hybrid FB25HB-11 (SN: M254-817001-)

The manual comprises two Workshop Manuals

1. Workshop Manual (BBB11E1-02_SM)

Format: PDF, 422 pages

Language: English

Table of Contents:

INDEX

Foreword

PRECAUTIONS WHEN PERFORMING THE SERVICE WORK

description of the symbols

GENERAL AND SPECIFICATIONS

Outside view and specifications

SAFETY ITEMS FOR MAINTENANCE

standard tightening torque for bolts

STANDARD TIGhTENING TORQUE FOR PIPE JOINTS

How to use LOCTITE

conversion table

PERIODIC REPLACEMENT OF CONSUMABLE PARTS

TESTING AND ADJUSTING

Service data (1.0 - 1.75 tON models)

Service data (2.0 - 3.0 tON models)

How to operate lift interrupt function

How to reset electrolyte level indicator function

How to start hour meter

Operation of meter panel

Adjusting lowering speed of fork

(PROPORTIONAL SOLENOID VALVE)

Battery

Fuse

Transfer case

Stationary charger

Brake pedal

Wheel brake

Adjusting parking brake lever

Hydraulic tank

Rear axle (Steering axle)

Mast (1.0 - 1.75 ton models)

Mast (2.0 - 3.0 ton models)

fork carriage (1.0 - 1.75 ton models)

fork carriage (2.0 - 3.0 ton models)

Measuring hydraulic drift of hydraulic cylinder and hydraulic drift of leaning forward

Bleeding air

Removal and installation

Arrangement of units

Weight of each unit (1.0 - 1.75 ton models)

Weight of each unit (2.0 - 3.0 ton models)

General disassembly and assembly drawing

Mast

Lift cylinder

Power train (Front axle + Transfer + Drive motor)

Rear axle

Battery

EPS actuator

Steering gear box

Hydraulic pump + Pump motor

Disassembly and assembly

Transfer (1.0 - 1.75 ton models)

Transfer (2.0 - 2.5 ton models)

Transfer (3.0 ton model)

Differential (1.0 - 1.75 ton models)

Differential (2.0 - 3.0 ton models)

Front axle (1.0 - 1.75 ton models)

Front axle (2.0 - 2.5 ton models)

Front axle (3.0 ton model)

Brake master cylinder

Damping cylinder

Wheel brake (1.0 - 1.75 ton models)

Wheel brake (2.0 - 2.5 ton models)

Steering gear box

EPS actuator

Wheel brake (3.0 ton model)

Rear axle (1.0 - 1.75 ton models)

Rear axle (2.0 - 3.0 ton models)

Lift cylinder

tilt cylinder (6 /12 )

Hydraulic pump

Control valve (Proportional solenoid valve spec.)

Control valve (Manual valve spec.)

pump motor

Drive motor

MAINTENANCE STANDARD

Transfer

Differential (1.0 - 1.75 ton models)

Differential (2.0 - 3.0 ton models)

Front axle (1.0 - 1.75 ton models)

Front axle (2.0 - 2.5 ton models)

Front axle (3.0 ton model)

Brake master cylinder

Damping cylinder

Wheel brake (1.0 - 1.75 ton models)

Wheel brake (2.0 - 2.5 ton models)

Wheel brake (3.0 ton model)

Rear axle (1.0 - 1.75 ton models)

Rear axle (2.0 - 3.0 ton models)

Lift cylinder

Tilt cylinder

Control valve (Proportional solenoid valve spec.)

Control valve (Manual valve spec.)

Hydraulic pump

Mast, fork carriage, and fork (1.0 - 1.75 ton models)

Mast, fork carriage, and fork (2.0 - 3.0 ton models)

Drive motor (1.0 - 2.5 ton models)

Drive motor (3.0 ton model)

Pump motor (1.0 - 1.75 ton models)

Pump motor (2.0 - 3.0 ton models)

Power steering motor

Structure and function

Power train

Travel system

Braking device

Steering system

Hydraulic system

Hydraulic control valve (Proportional solenoid valve spec.)

Work equipment

Power connector for optional devices

Control unit

Operating device (Meter panel, switches, etc.)

TROUBLESHOOTING

Controller

Main controller

Drive motor

Electric circuit diagram (A3)

Electric circuit diagram (A3)

Electric circuit diagram (A3)

Electric circuit diagram (A3)

Electric circuit diagram (A3)

Sub controller

Troubleshooting

SELF-DIAGNOSIS LOGIC TABLE (1.0 - 3.0 ton models)

CHARGER

Yearly inspection criteria

Starting motor and pump motor

Battery

Controller

Power train

Travel system

Steering system

Brake system

Cargo handling system

2. Workshop Manual: SUPPLEMENT for BE30 Hybrid Series (BHB11E1-02_SM)

Format: PDF, 167 pages

Language: English

Table of Contents:

FOREWORD

GENERAL AND SPECIFICATIONS (Use along with Shop Manual BBB11E1-02.)

TESTING AND ADJUSTMENT (Use along with Shop Manual BBB11E1-02.)

REMOVAL AND INSTALLATION (Use along with Shop Manual BBB11E1-02.)

DISASSEMBLY AND ASSEMBLY (See Shop Manual BBB11E1-02.)

MAINTENANCE STANDARD (See Shop Manual BBB11E1-02.)

STRUCTURE AND FUNCTION (See Shop Manual BBB11E1-02.)

TROUBLESHOOTING (Use along with Shop Manual BBB11E1-02.)

YEARLY INSPECTION CRITERIA

CONVERSION TABLE

General

Language

EnglishModel of Truck

FB20HB-11, FB25HB-11Region

WorldWideType of Document

Workshop ManualType of Truck

Forklift TruckReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.